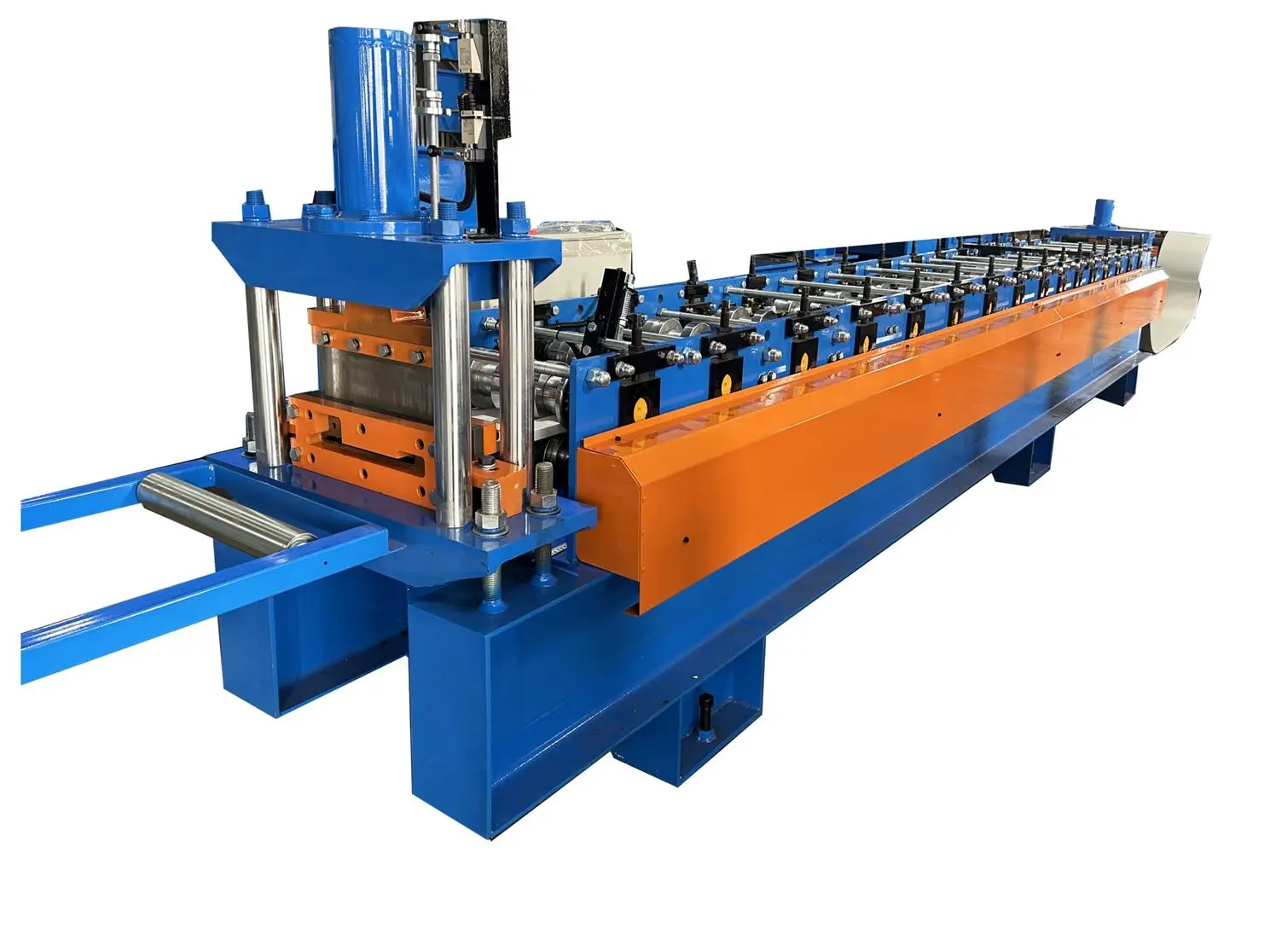

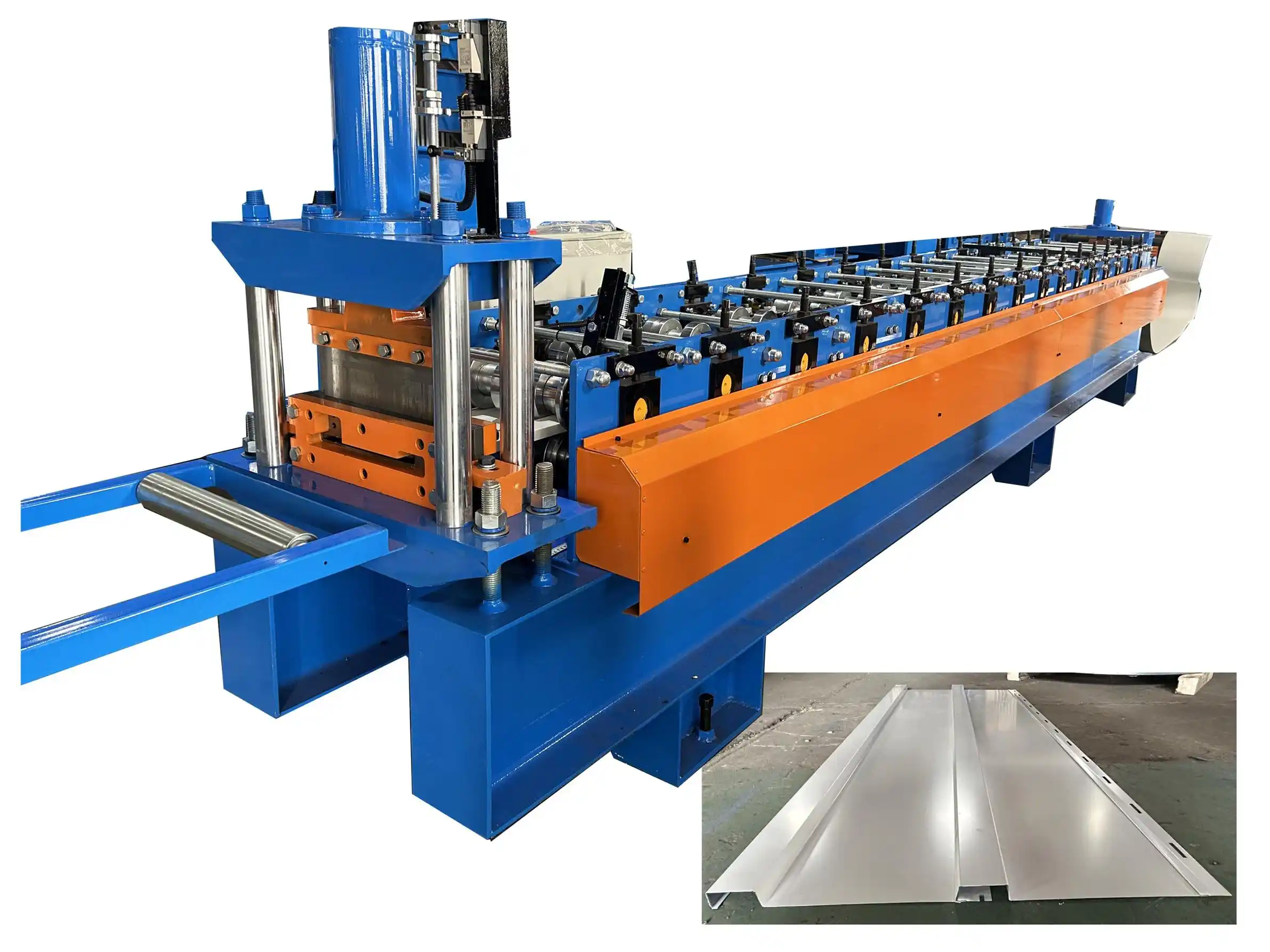

The C Purlin Roll Forming Machine is a high-efficiency, multifunctional metal forming device designed for the production of various specifications of C-shaped purlins. This machine integrates multiple processes, including decoiling, leveling, forming, punching, and cutting, achieving a fully automated production flow that significantly enhances both productivity and product quality.

Our C Purlin Roll Forming Machine is equipped with advanced hydraulic cutting technology, ensuring precise geometric profiles of the formed sheets while generating zero waste, effectively reducing production costs. The computer-controlled length measurement system guarantees high precision and user-friendly operation. Additionally, the machine features an automatic flying saw punching function, enabling precise elliptical or custom-shaped hole punching on the purlins with adjustable hole spacing to meet diverse customer needs.

The C-shaped purlins produced by this machine offer excellent bending and compression resistance, ensuring superior straightness and easy installation. They are widely used as primary load-bearing structures in large and medium-sized industrial and civil buildings, such as factories, warehouses, locomotive garages, and aircraft hangars. This machine is an indispensable piece of equipment in the steel structure construction industry.

Our Advantages

Since 2010, we have been dedicated to the professional manufacturing of various cold roll forming machines, accumulating extensive experience in design and production. With a highly skilled technical team, we offer customized design services, including personalized color and logo customization, to meet the unique needs of our clients. Our expert professionals and skilled workers work diligently to ensure that every machine meets the highest quality standards.

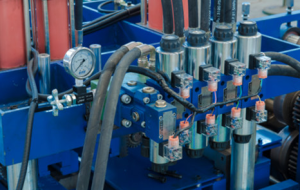

We utilize the Schneider PLC system, ensuring high-precision operation and user-friendly control. With a fully automated mode, simply input the required sheet length and quantity, and the machine will start working according to your order requirements, significantly improving production efficiency.

Our machines have been successfully exported to more than 20 countries and regions, including Southeast Asia, the Middle East, Africa, North America, and South America, earning widespread recognition and trust. We take pride in our professional team, well-established production system, high-quality products, and excellent service, all aimed at providing comprehensive solutions for our customers.

Additionally, we guarantee that within one year, any damaged parts caused by quality issues will be replaced free of charge, ensuring that our customers’ rights and interests are fully protected.

Technical | |

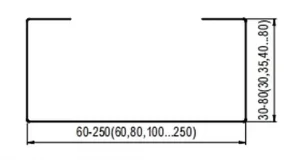

| Size | C60-250 |

| Dimension | 7800*1600*1600mm |

| Hydraulic Motor Power | 15KW |

| Motor Power for adjusting C size | 0.37kw*2+0.75kw |

| Motor Power for guiding | 0.18kw*2 |

| Motor Power for adjusting punching hole | 0.18kw*2 |

| Forming Speed | 0-30m/min |

| Voltage | 380V/50HZ/3PH |

| Effective Width | 60-250mm |

| Material Width | 122-402mm |

| Flange Height of Purlin | 30-80mm |

| Material Thickness | 0.8-2.2mm |

| Control System | PLC Computer Control |

| Material for All Roller | 45# Steel Chrome-faced |

| Material for Shaft | 40Cr steel |

| Material for cutter | Cr12Mov |

Components of the C Purlin Roll Forming Machine

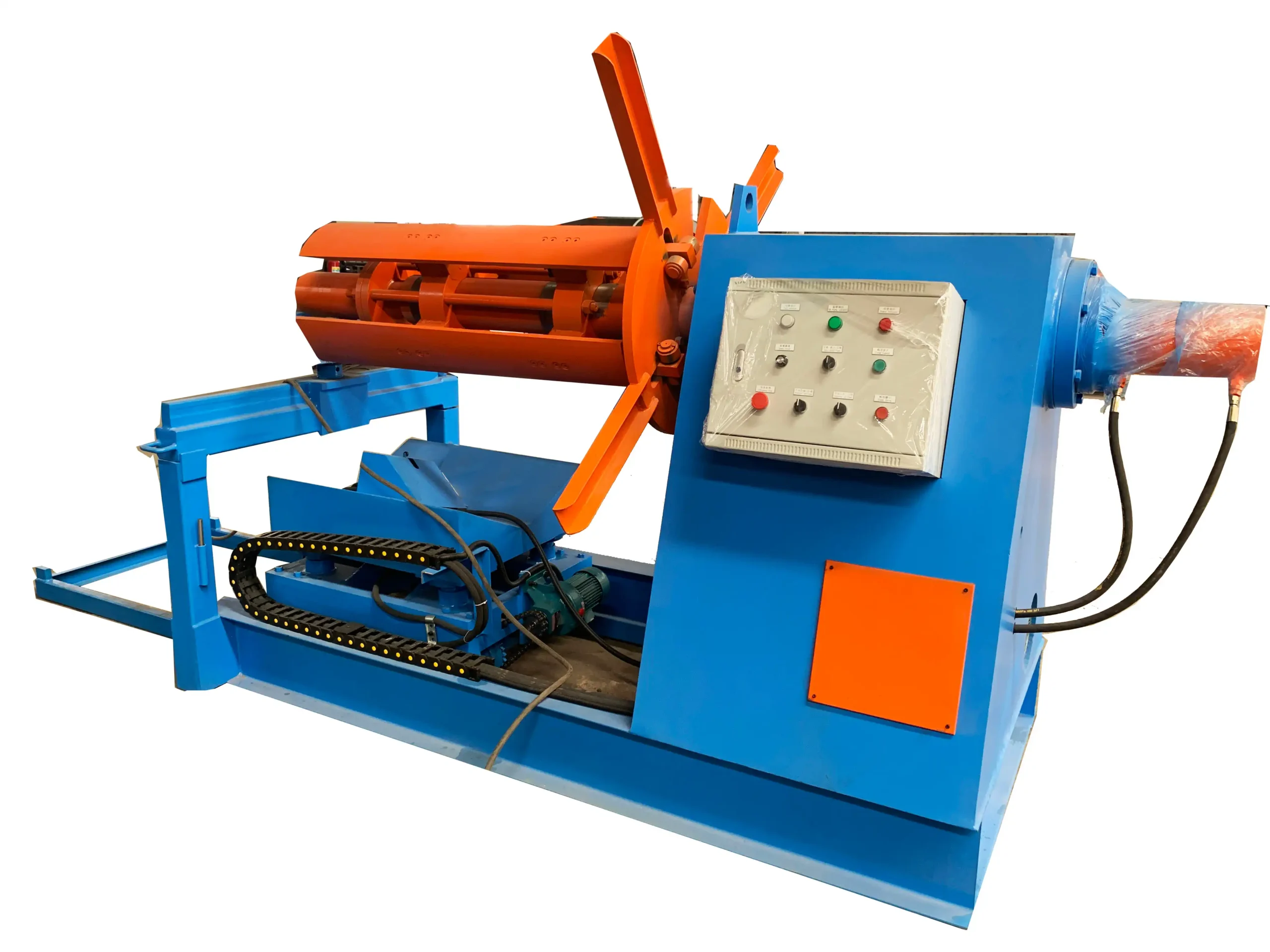

C purlin machine feed material leveling

Function: Leveling the material before feeding it into the roll forming machine to ensure uniform flatness and correct shape of the material when it enters the machine.

Features: The machine may be equipped with an automatic adjusting device that can adaptively adjust to the characteristics and thickness of different materials to achieve the best leveling effect.

Pre-punching device

Function: Performs punching operations on the flat sheet according to preset specifications and positions.

Control mode:

PLC controls the number of punching holes and horizontal position to ensure the accuracy and consistency of punching position.

The vertical position is manually adjusted to suit different punching needs and material thickness.

Punching Parameters:

The number and size of punched holes can be customized according to specific customer requirements.

The range of hole diameters may cover from 0.5 mm to 15 mm and the hole spacing can be adjusted from 1 mm to 50 mm.

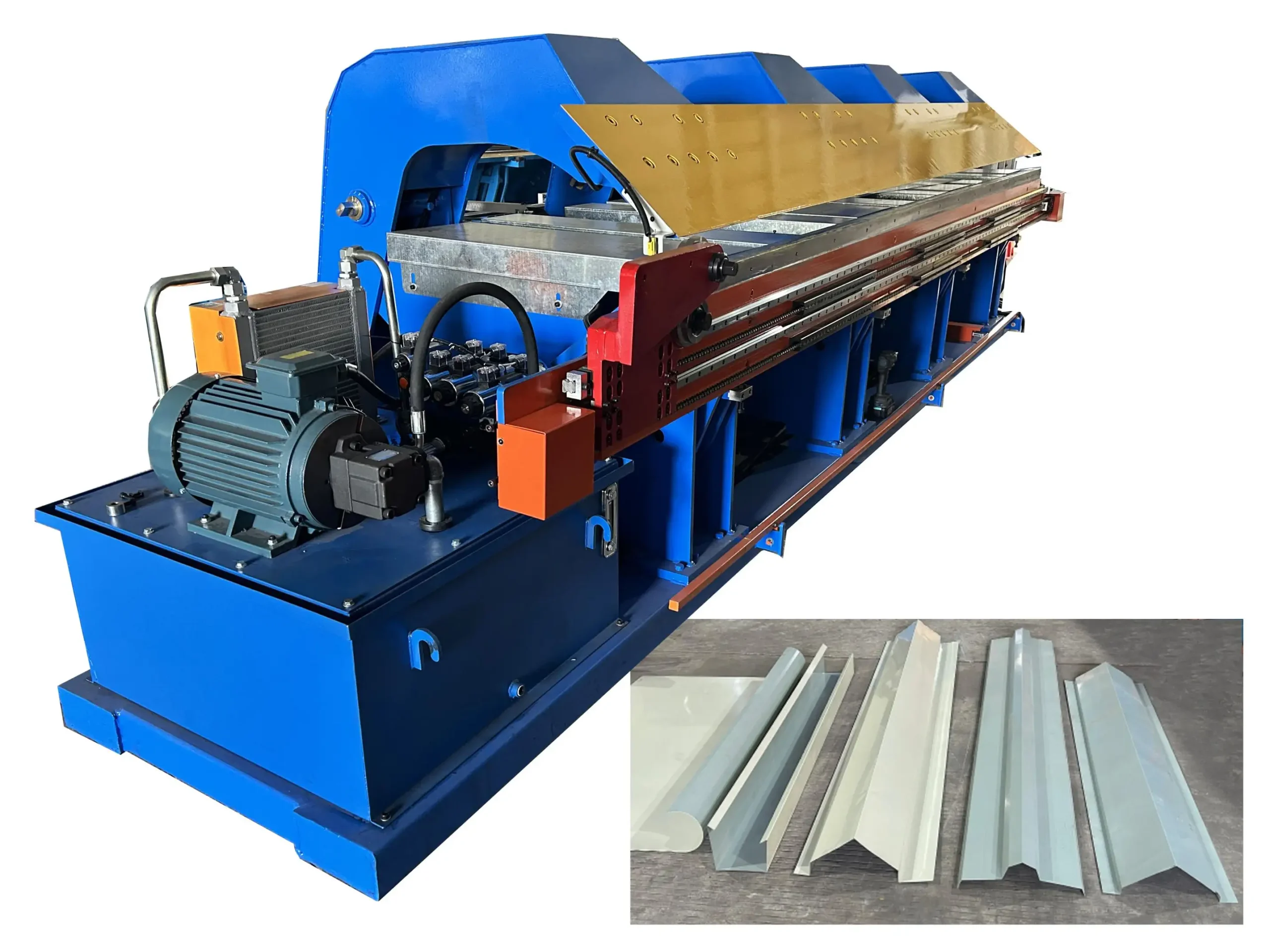

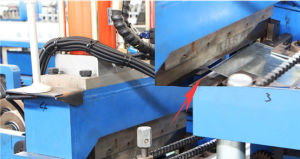

Pre-cutting device

Function: Preliminary trimming and cutting of raw material prior to rolling for subsequent processing and molding.

Features: With possible automated operation, this device can quickly and accurately complete the pre-cutting of raw materials, improving productivity and processing quality.

Universal molding cutter (optional)

Function: It is used for further cutting and trimming of already formed C purlins to meet different lengths and shapes.

Features:

High versatility, can adapt to many different sizes and shapes of C purlin cutting needs.

It may be equipped with high-precision cutting system and safety protection device to ensure cutting precision and operation safety.

C purlin main machine

C purlin main machine is the core equipment in the C-Pullin machine production line, featuring high precision molding, high productivity, adjustability, and stability. By cooperating with other auxiliary equipment, it can efficiently and stably produce C-purlin products that meet customers’ demands.

Features of C Purlins

Lightweight & High Strength: Designed with a thin-walled structure, C purlins are lightweight yet strong, capable of bearing significant loads.

Excellent Section Performance: The optimized cross-sectional shape maximizes the mechanical properties of steel, enhancing load-bearing capacity.

Easy Installation: C purlins are easy to process, install, and dismantle, significantly reducing construction time and costs.

Cost-Effective & Practical: With great economic value and versatility, C purlins meet the needs of various construction and mechanical manufacturing applications.

The applications of C purlins

The applications of C purlins are wide-ranging. Here is a detailed introduction to their main application fields:

1. Construction Industry

Roof Support:

C purlins are commonly used as support structures for roofs, capable of bearing the weight of the roof and transferring the load to the trusses or walls. In pitched roofs, C purlins are typically placed on trusses or inclined beams, with a layer of roofboard and waterproofing material laid on top, serving as components for water drainage.

In steel structure buildings, C purlins play an essential role in roof structures, arranged transversely on trusses or rigid frames, forming a critical support element of the roofing system. They effectively support roofing materials such as color steel plates and sandwich panels, handling various loads such as dead loads (weight of roofing materials), live loads (weight of personnel during roof maintenance, snow load, etc.), and wind loads.Wall Fixation:

C purlins can also be used to fix and support walls, especially in steel structure buildings. As wall beams, they enhance the stability and load-bearing capacity of the walls. In some construction projects, the shape and dimensions of C purlins facilitate connections with various wall structures, and their flanges can be easily fixed to wall materials using self-tapping screws, rivets, and other fasteners.Structural Components:

C purlins can be combined to form lightweight roof trusses, brackets, and other building components, used to construct light roof structures and wall structures that bear lateral loads.

2. Mechanical Manufacturing Industry

In mechanical manufacturing, C purlins are often used as columns, beams, and arms, providing support and fixation for mechanical equipment.

3. Other Applications

C purlins are also widely used in various industries, including:

Automotive

Railway vehicles

Building doors and windows

Transportation

Shelving

Electrical cabinets

Highway guardrails

Shipping containers

Steel formwork and scaffolding

Solar panel supports

Shipbuilding

Bridges

Transmission towers

Steel sheet piles

Cable trays

Agricultural machinery

Furniture

Storage

Rails

Drywall studs

Greenhouses

Pipe supports

Municipal construction, and more.