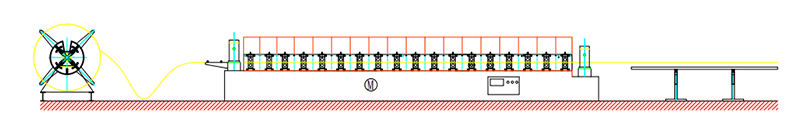

Metal Floor Machine er et avanceret udstyr designet til produktion af metalgulvplader af høj kvalitet. Pladeformningsmaskinen består af en afvikler og dens base, en spolestyringsenhed, et rulleformningssystem, en efterskæringsenhed, en hydraulisk station og et udgangsbord for at sikre nøjagtig formning og effektiv produktion af gulvplader.

Vores virksomhed har vundet stor anerkendelse inden for produktion af metalgulve for sin effektive, stabile og præcise ydeevne. Vi ser frem til at etablere et langsigtet og stabilt samarbejdsforhold med dig.

Egenskaber og anvendelsesfordele ved metalgulvmaskiner

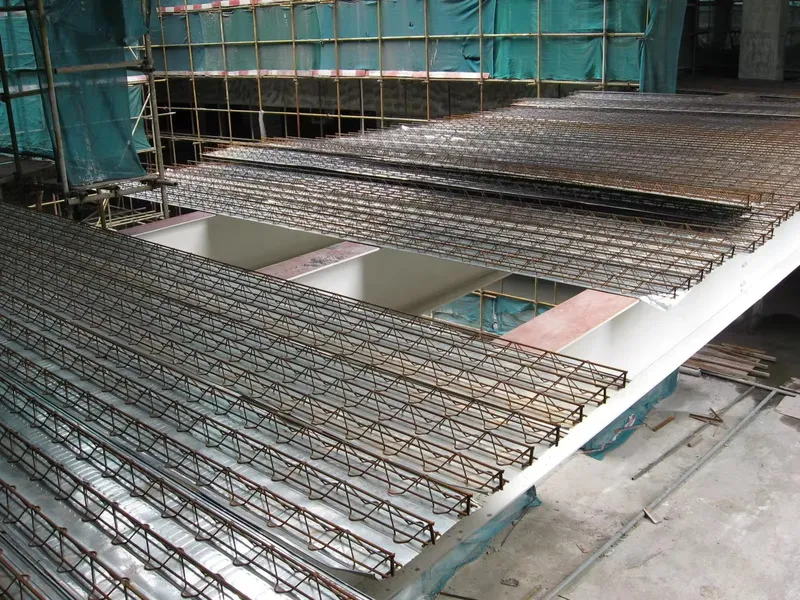

På grund af sine mange fordele har metalgulve støt og roligt erstattet konventionelle gulve som et banebrydende bygningselement i byggesektoren. Det vigtige stykke maskineri, der bruges til at skabe dette højtydende gulv, metalgulvsmaskinen, har også sin egen tiltrækningskraft.

1. Materialets enestående ydeevne

På grund af dets overlegne mekaniske egenskaber og øgede belastningskapacitet skiller metalgulve sig ud og øger i høj grad en bygnings samlede stabilitet. Desuden giver bygningens enestående modstandsdygtighed over for brand, korrosion og vejrlig en stærk garanti for dens levetid og sikkerhed.

2. Let at bruge og effektiv konstruktion

Den præfabrikationsteknologi, der bruges i produktionen af metalgulvmaskinen, giver mulighed for en hurtig og nem installationsprocedure. Det reducerer ikke kun den tid, det tager at bygge, men det mindsker også behovet for ekspertpersonale, hvilket sænker lønudgifterne. Desuden er der som følge af mindre svejsning og skæring på stedet også færre sikkerhedsrisici i hele byggeprocessen.

3. Bemærkelsesværdige stordriftsfordele

Metalgulve kan i starten koste lidt mere at købe end almindelige gulve, men der er flere langsigtede fordele, som gør det umagen værd. For det første kan projektet afsluttes og tages i brug hurtigere, hvilket giver fordele forud for tidsplanen, da byggetiden er blevet reduceret. For det andet har et metalgulv forholdsvis minimale vedligeholdelsesomkostninger og forlænger bygningens levetid på grund af dets modstandsdygtighed. Brug af metalgulve kan sænke de samlede byggeomkostninger, når alle disse aspekter tages i betragtning.

4. Bæredygtighed og miljøbevarelse

Fordi metalgulve kan genbruges og genanvendes, er det en god mulighed for at håndtere byggeaffald. Produktionen af byggeaffald og de skadelige virkninger på miljøet kan reduceres betydeligt ved at genbruge og genanvende metalgulve. Samtidig er det i overensstemmelse med principperne for bæredygtig udvikling og grønt byggeri, hvilket tilskynder byggesektoren til at bevæge sig i en mere miljøvenlig og bæredygtig retning.

Maskinens tekniske parametre

| Nej. | Vare | Parameter |

| 1 | Maskinens størrelse | 11000*2200*1600mm |

| 2 | Maskinens vægt | 11000 kg |

| 3 | Maskinkraft | 18,5 kW |

| 4 | Hydraulisk motor | 3,7 kW |

| 5 | Rullehastighed | 0-18m/min |

| 6 | Rullestationer | 22 |

| 7 | Materiale til rulle | 45#Stål |

| 8 | Effektiv bredde | tilpasset |

| 9 | Fodringsbredde | 1219 mm |

| 10 | Spænding | 380V 50Hz 3PH/Tilpasset |

| 11 | Materialets tykkelse | 0,8-1,2 mm/tilpasset |

| 12 | Kontrolsystem | Schneider/Delta/Tilpasset |

Profiler af maskiner til gulvbelægning

Arbejdsflow

Afvikler→Fødeanordning→Forskæreanordning (valgfri)→Rulleformningssystem→Hydraulisk stolpeskæreanordning→Udgangsreol

Maskinens komponenter

- Fodring

- Hydraulisk forskærer

- Ruller til gulvbelægningsmaskine

Rullerne er lavet af højkvalitets lejestål GCr15, CNC-drejet, varmebehandlet og fås med hårdkrombelægning.

Med materialestyring, karosseriramme fremstillet af 300# H-type stål ved svejsning

- Gulvbelægningsmaskine til formning af fræser

Fremstillet af højkvalitetsformstål Cr12 med varmebehandling

- PLC-kontrolsystem

Let at betjene

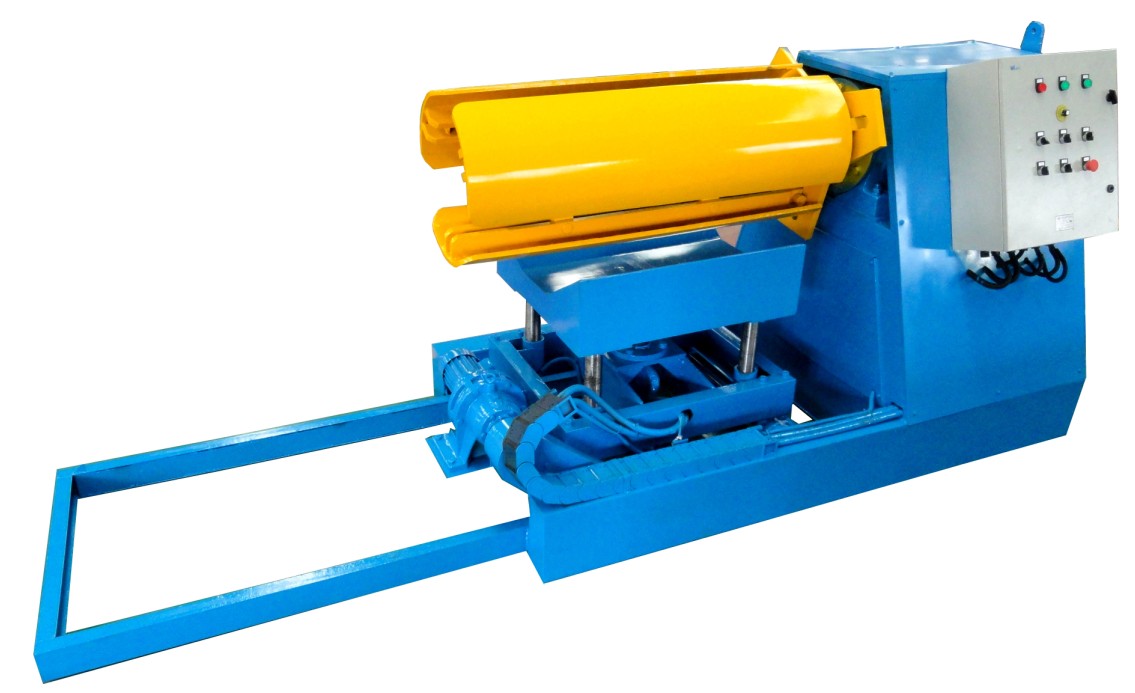

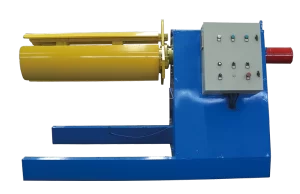

6.Døkoiler

Manuel afvikler: et sæt

Udrevet, manuel kontrol af krympning og stop af stålspiralens indre boring

Maks. indføringsbredde: 1250 mm, spole-ID-område 480 mm ± 30 mm

Kapacitet: Maks. 5 ton

Med 5 tons hydraulisk aftrækker med bil og uden bil som ekstraudstyr

Vores tjenester

Produktkvalitet og fremstilling

- Udvælgelse af råmaterialer: For at garantere produktets styrke og slidstyrke bruger vi førsteklasses stål, såsom Cr12-formstål og GCr15-lejestål, i produktionen af vores metalgulvplader.

- Forarbejdningsteknologi: Varmebehandling bruges til at forbedre materialets ydeevne, og CNC-drejebænke bruges til præcis forarbejdning. For yderligere at forbedre slidstyrken er rulleoverfladen belagt med hårdkrom.

- Streng kvalitetskontrol: For at garantere, at alt udstyr opfylder kundernes krav og nationale standarder, gennemføres der streng kvalitetskontrol i alle faser af fremstillingsprocessen, fra indkøb af råmaterialer til montering og idriftsættelse.

Tilpasset service

Tilpasning af specifikationer: Vi leverer en række forskellige modeller og specifikationer af rulleformningsmaskiner til metalgulve for at imødekomme vores kunders krav.

Tilpasning af funktioner: Vi kan ændre visse udstyrsfunktioner, herunder automatisk fodring og detektion, i overensstemmelse med vores kunders produktionskrav.

Service efter salg

- Installation og idriftsættelse af udstyr: For at sikre, at udstyret bliver integreret i produktionen, tilbyder vi installation, idriftsættelse og prøvedrift af udstyret.

- Træning i betjening: For at sikre, at operatørerne er kompetente til at bruge og vedligeholde udstyret, skal du give kunderne træning i betjening.

- Reparation og vedligeholdelse: Sørg for rutinemæssig vedligeholdelse og vedligeholdelsesservice for at sikre, at udstyret fungerer stabilt på lang sigt.

- Teknisk assistance: Hjælp kunderne med problemer, der opstår i forbindelse med brugen, ved at tilbyde teknisk support og konsulenttjenester.