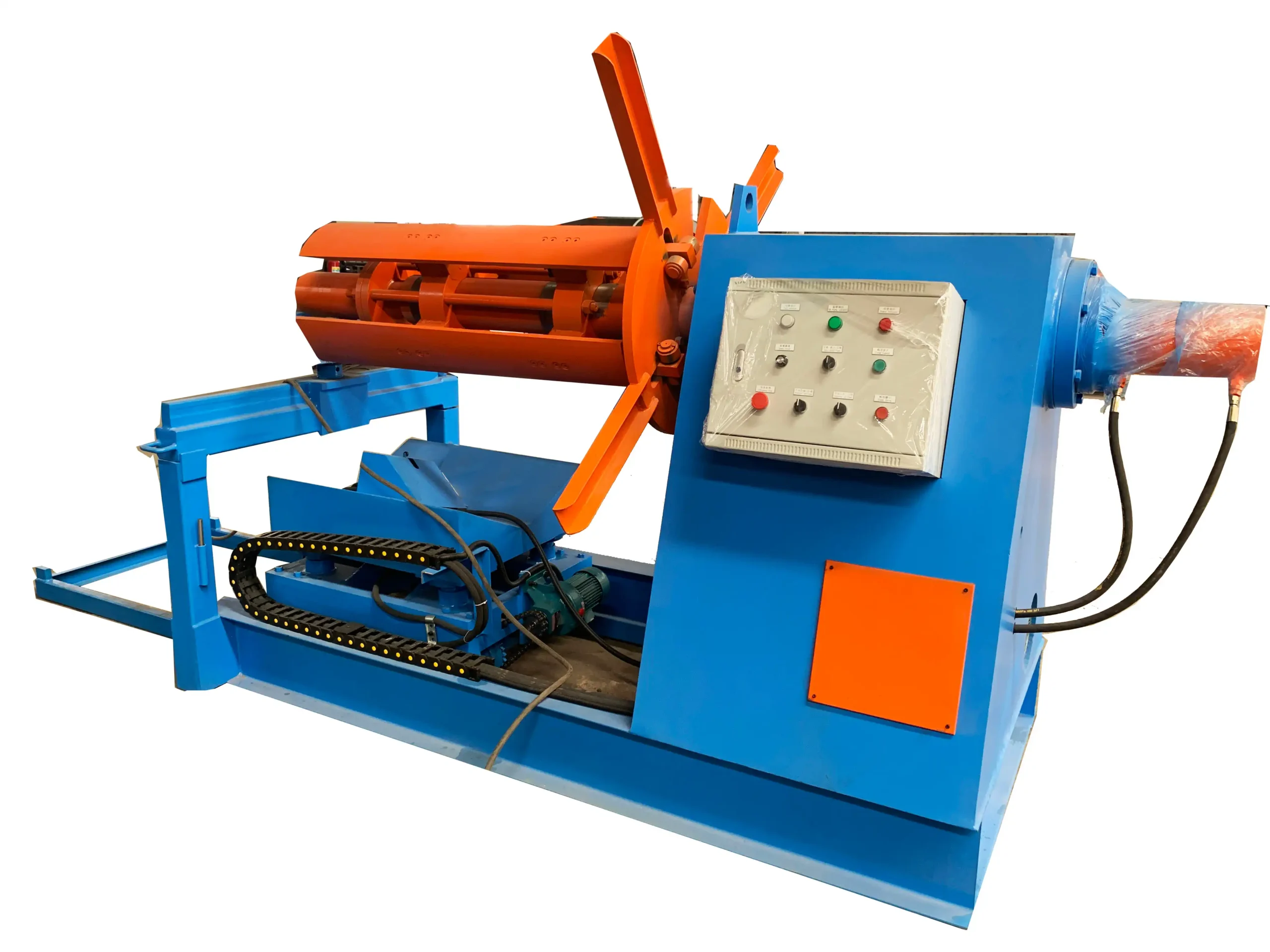

Feature of Hydraulic Uncoiler

Designed specifically for 1250mm diameter coil processing, this 6-ton fully automatic decoiler integrates intelligent control modules and dynamic adjustment mechanisms to achieve full-process optimization from coil loading to unwinding. The equipment adopts an expandable modular architecture, allowing users to customize configurations—such as pressure arm mechanisms and hydraulic servo tension systems—based on production line requirements, ensuring precise and stable unwinding tension under varying speeds and loads. Its key technical highlights include:

• High-Efficiency Production Cycle: Automation significantly reduces line changeover time and improves overall production efficiency.

• Intelligent Tension Coordination Control: A precision tension management system maintains uniform material feeding to minimize waste.

• Multi-Specification Adaptability: Through programmable logic controller (PLC) presets for various material parameters, the machine accommodates different types of coils, including cold-rolled, galvanized, and silicon steel coils, with thicknesses ranging from 0.3mm to 6mm and widths from 800mm to 1500mm.

As a critical pre-processing unit in continuous rolling production lines, this decoiler not only ensures long-term operational reliability through reinforced structural design and a fault self-diagnosis system but also helps enterprises enhance production stability while reducing single-shift operator requirements by 40%, thanks to its human-machine interface and production data traceability functions.

Decoiler Datos técnicos

| Talla | 4500*1200*1600mm |

| Peso | 800KGS |

| Tensión | 220V/60HZ/3PH(se puede personalizar) |

| Potencia del motor | 4KW |

| Potencia hidráulica | 1,5 KW |

| Diámetro interior | 450-550 mm |

| Diámetro exterior | Máx.1500mm |

| Max. Carga | 5 toneladas |

| Máx. Ancho de bobina | 1250 mm |