A light-gauge steel machine bends thin steel sheets into tough building pieces. This machine is very important in building today. It gives strength and lasts longer than some old materials. In the last ten years, builders have started using these machines more. There are a few reasons for this:

- More people live in cities, and more buildings are made

- New rules for building and better technology

- People care more about safety and protecting the environment

These changes show why it is important to know how a steel machine works if you build things today.

Steel Machine Overview

Definition

A steel machine changes thin steel sheets into strong parts. It uses special technology to make studs, tracks, and joists. These machines work without heating the steel. This keeps the steel strong and correct in shape. There are many kinds of light gauge steel machines. Some popular ones are:

- Light Gauge Steel Framing Station with a framing table and screw tool carriages

- Interior Hand Framing Line

- Interior Line

- Combo Line

- 2-Table Line

- 3-Table Line

- 3-Table Router Line

Manufacturers use tools like roller conveyors and power conveyors. They also use swing gates, panel lifts, and handlebar routers. These tools help move panels and parts quickly. Each steel machine is made for easy use and some automatic fastening. Builders use these machines for off-site building, modular homes, and panel projects.

Purpose

A steel machine helps builders make exact framing parts for many jobs. It shapes steel sheets into frames, trusses, and joists. These machines help make frames, trusses, modular homes, special facades, mezzanine floors, stairs, roofs, and emergency houses.

Note: Steel machines often work with CAD and BIM software. This helps builders design custom shapes with great accuracy.

The roll-forming process in each steel machine makes building faster. It also cuts down on waste and makes the building stronger and better for the planet. Builders pick these machines to build faster, safer, and with better quality.

How It Works

Roll Forming Process

A light gauge steel machine changes steel coils into building parts step by step. Here is how it works:

- Workers put a steel coil on the decoiler.

- The coil unwinds and sends a strip into a straightener.

- The straightener fixes any bends or problems in the strip.

- The strip goes into the steel machine and may pass through a pre-punch press.

- The machine uses forming rolls to shape the strip. Each roll changes the strip a bit more until it looks right.

- The machine straightens the finished shape to fix any new bends.

- The machine cuts the piece to the right size and stacks it.

Tip: This way, the steel machine makes strong and exact parts fast with little waste.

Automation is very important in this process. The steel machine does feeding, shaping, cutting, and stacking all together. This means less handwork and every part is of the same quality.

CAD/CAM Integration

Modern steel machines link to CAD/CAM software. This gives many benefits:

- Engineers use the software to design framing parts with exact sizes.

- The design files go right to the steel machine, so there are no mistakes.

- Real-time checks make sure the design is strong and safe before making parts.

- The system uses smart connections and cloud data, so managers can watch production and fix issues fast.

Note: CAD/CAM makes work faster and more dependable. Builders can also make special shapes and sizes for each job.

Production Speed

Production speed is a big reason to use a steel machine. These machines work much faster than people can by hand. Roll forming is a nonstop, automatic process that makes many parts quickly. Some machines can make up to 2,200 meters of steel framing in one hour.

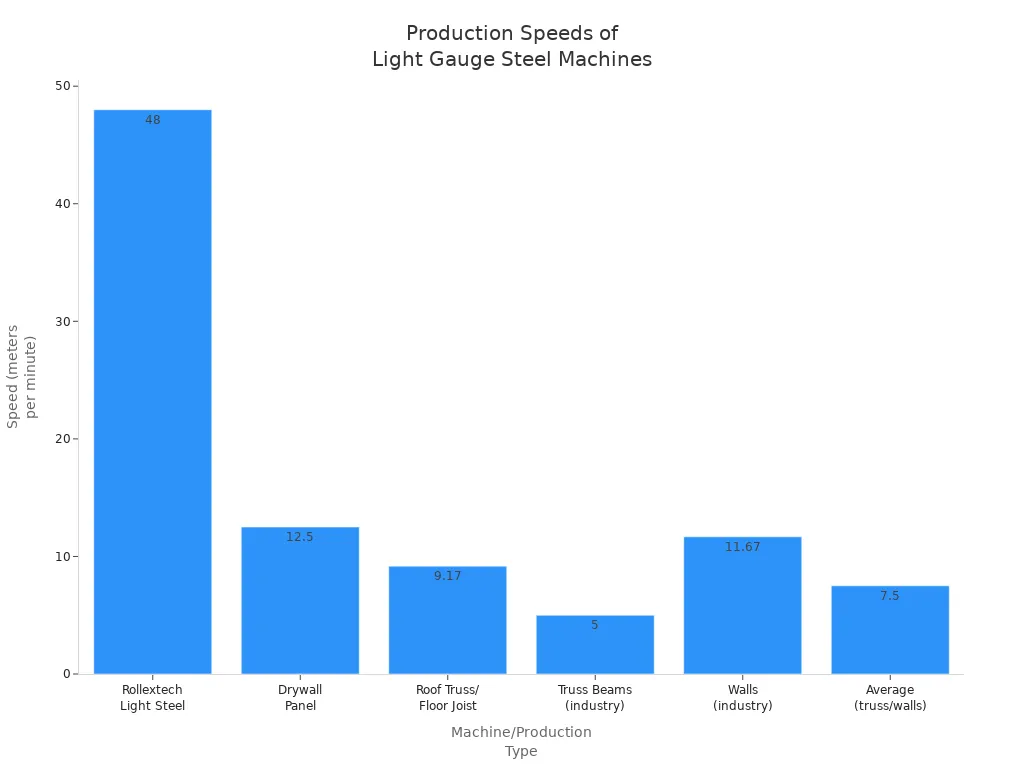

The table below shows how fast different light-gauge steel machines work:

| Machine/Production Type | Production Speed (meters per minute) | Notes |

|---|---|---|

| Rollextech Light Steel Framing | Up to 48 | Maximum speed excluding punching/cutting |

| Drywall Panel Production | 12.5 | Converted from 750 meters per hour |

| Roof Truss/Floor Joist Production | 9.17 | Converted from 550 meters per hour |

| Truss Beams (general industry) | 5 | Converted from 300 meters per hour |

| Walls (general industry) | 11.67 | Converted from 700 meters per hour |

| Average (truss beams & walls) | 7.5 | Approximate average speed |

Fast production helps construction in many ways:

- Off-site building lets different jobs happen at once, so projects finish faster.

- Exact engineering means fewer changes and fixes at the site.

- Factories make parts inside, so bad weather does not slow things down.

- Site work and making modules can happen together, which speeds up the project.

- Faster making and building means projects end sooner, saving money and giving better results.

In short, a steel machine with roll forming and CAD/CAM gives fast, accurate, and efficient work. This is why it is a great choice for building today.

Steel Machine Features

Key Components

A steel machine has many important parts that work together. Each part does a special job to help shape steel for building. The Decoiler puts steel coils into the machine and keeps them straight. Rolling Stations use rollers to bend the steel into the right shape. Hydraulics give the power needed to form and punch the steel. Electrical Systems control how fast and when the machine works. The Tool Head holds special dies and punches to make different shapes and holes. Software changes digital designs into steps for the machine, so it can work by itself and be very exact. The machine also makes parts like studs, tracks, headers, bracing, and connections. These parts are used to build walls, floors, and roofs. The machine can add things like dimples, notches, and holes for wires or pipes.

Note: It is important to check bolts and guides often. This keeps the steel machine safe and working well.

Automazione

Modern steel machines use smart automation to work faster and better. They connect to 3D design programs and use robots to help make parts. This lets the machine make many steel shapes without stopping to change tools. Automation means workers do less by hand, so there are fewer mistakes and things get done faster. Machines can change between steel sizes and shapes quickly. Digital systems watch the work as it happens, so problems can be fixed fast. Robots help put parts together, which makes building easier.

Automation helps builders finish jobs faster and save money. It also keeps the quality of the work high.

Sicurezza

Safety is very important for every steel machine. Automated systems mean workers do not have to touch heavy steel or sharp tools. Machines have safety guards, emergency stops, and sensors to stop accidents. Digital controls watch the machine and can stop it if something is wrong.

Tip: Safety features protect workers and help keep projects on time.

Vantaggi

Speed and Efficiency

Light-gauge steel machines help teams build much faster. These machines can make framing parts very quickly. Sometimes, they make thousands of meters in one hour. This fast work lets builders finish big buildings or units sooner. Automated systems mean less handwork. This lowers mistakes and keeps things moving well. Teams can work on different building parts at once. This makes the whole job go smoother and faster.

Precision and Quality

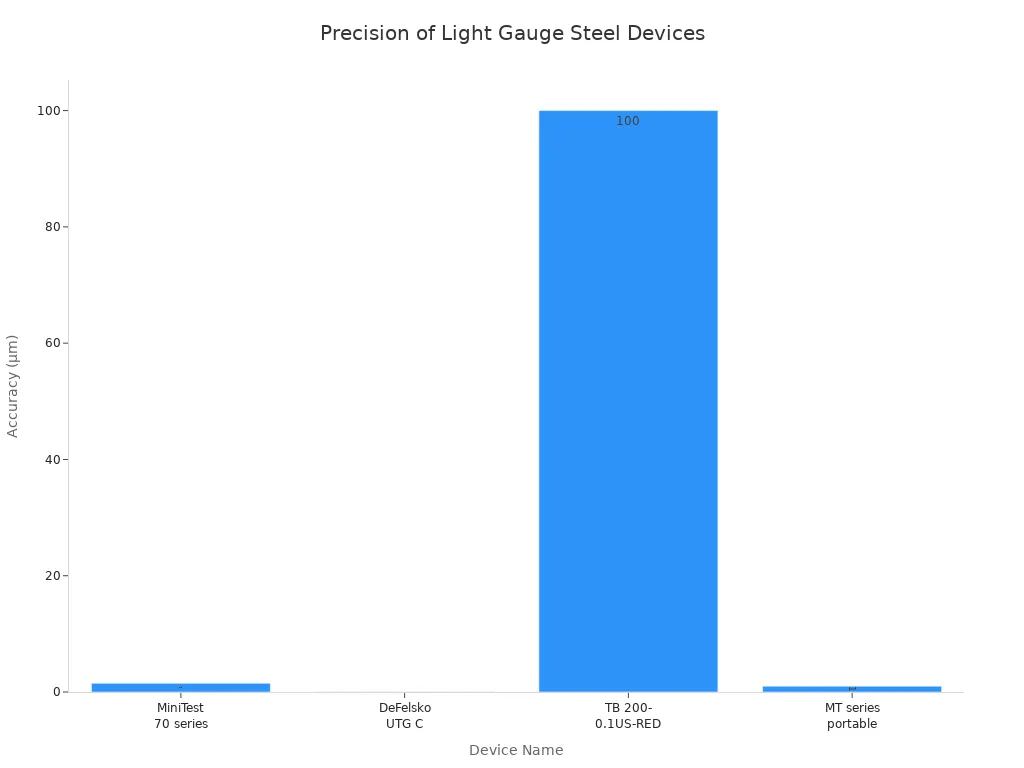

Modern machines are very accurate. They use special tools to measure thickness and shape. These tools can check down to a few microns. The table below shows how exact these tools are:

| Device / Gauge Name | Measuring Range | Measurement Accuracy | Resolution |

|---|---|---|---|

| MiniTest 70 series | 0 mm – 3 mm | 1.5 µm | 0.5 µm |

| DeFelsko UTG C ultrasonic | 1 mm – 125 mm | 0.03 µm | N/A |

| TB 200-0.1US-RED | 1.5 mm – 200 mm | 0.1 mm (100 µm) | N/A |

| JCT 100 coating thickness | Up to 2,000 µm | N/A | 1 µm |

| MT series portable gauge | 0.65 mm – 600 mm | 0.1 / 0.01 / 0.001 mm | N/A |

| PosiPen® pen-type gauge | 5 µm – 500 µm | N/A | N/A |

This kind of accuracy makes sure every part fits right. This helps buildings stay strong and safe. Quality checks look at each piece. Builders can trust that the parts are good.

Durability and Versatility

Buildings made with light-gauge steel last a long time. Many metal buildings stay strong for 40 to 70 years. Some last over 100 years if cared for well. Many things help them last longer:

- Galvanized steel and coatings stop rust and weather damage.

- Regular checks and care keep the building in good shape.

- Good building habits stop early problems.

- Some old steel buildings from the 1900s still work today.

Modern machines can make many kinds of building parts. They make wall studs, roof trusses, and custom shapes for special jobs. For example, FRAMECAD machines can make one or many types of profiles. This helps build homes, offices, modular units, and shelters. The table below shows what these machines can make:

| Machine Series | Profile Types Produced | Typical Applications |

|---|---|---|

| ScotPanel | C-section profiles (walls, roofs, trusses) | Residential, light commercial, modular, industrial projects; offsite fabrication |

| ScotTruss | Hat-channel steel trusses | Roof and floor trusses for residential, commercial, industrial buildings; offsite and mobile factory |

| KFS Framemaker | Structural stud and track profiles | Structural framing for residential, commercial, light industrial projects |

| KFD Framemaker | Non-structural track and stud profiles | Drywall, ceiling, curtainwall framing |

| KSE Series | Specialty roll forming for roof sheathing and advanced framing | Wall and ceiling contractors, load-bearing and non-load-bearing structures, variable height ceilings |

Tip: Picking the right machine and taking care of it helps builders make strong, lasting, and flexible buildings for many needs.

Applicazioni

Construction Uses

Light gauge steel framing is used in many building jobs. Builders use these machines to make wall studs, roof trusses, floor joists, and ceiling frames. Modular and prefabricated buildings use this technology the most. Here are some ways it helps:

- Machines like Howick’s FRAMA™ roll-forming units make steel parts very exact. They also make very little waste. This helps modular building go faster and makes it better.

- In Australia, the Broadmeadows modular project used these machines. They made framing much quicker, going from weeks to just days.

- The X-TENDA™ 3600 system makes steel panels that can get bigger at the building site. This can cut the time to install by half. This is very helpful for prefabricated buildings.

- Cold formed steel is strong but not heavy. It works well in earthquakes. This makes it a good pick for modular buildings in risky places.

- Using BIM and CAD software lets builders design exactly what they need. It also helps make parts fast. This means less extra work and faster installs.

- These machines help builders use less material and produce less waste. This is good for the environment.

Builders pick light gauge steel for schools, hospitals, hotels, and emergency shelters. It is fast, strong, and can be trusted.

Industry Sectors

Many types of businesses use light-gauge steel framing. Construction companies use it for homes, apartments, and offices. Hospitals and clinics use steel frames for quick building and long-term use. Schools and dorms are built with steel framing, too. Factories and warehouses use it for strong buildings. Groups that help after disasters use steel buildings for emergency homes and medical centers.

Selection Tips

Picking the right machine depends on what the project needs. Builders should think about what shapes they need, how fast the machine works, and how much is automatic. The machine must work with BIM and CAD software. This makes design and building easier. Safety and easy care are also important. Companies should buy machines from brands that give good help and training.

Tip: Always pick a machine that fits the project’s size and needs. This gives the best results.

Light-gauge steel machines let builders make strong frames fast. The decoiler, roll forming machine, punching station, and cutting station all work together. These parts help the machine stay quick and accurate. Builders use these machines for many projects, like homes and hospitals. They help avoid weather delays and finish jobs on time. Using this technology gives builders good results and meets many design needs.