In il costruzione e produzione industries, il domanda per lightweight, durable, e energia-efficiente materials has led a il widespread use di sandwich panels. These panels, known per their eccellente thermal insulation e strutturale strength, sono produced through specializzato machinery known come sandwich panel machines. Questo blog explores il chiave components, workflow, benefits, e trends associato con sandwich panel machines. Whether you’re a manufacturer looking a upgrade your produzione line o someone exploring questo technology per il first time, understanding questi machines può significativamente improve your produzione efficienza e prodotto quality.

What è a Sandwich Panel?

A sandwich panel è a type di composite building materiale consisting di two layers di altostrength metal sheets (usually steel o aluminum) bonded a an insulating core materiale in il middle. This “sandwich” structure combines lightweight design, eccellente strength, thermal insulation, e durability.

Esso offerte strutturale efficiency—tale come superior tensile e compressive strength from il dual metal layers, mentre il lightweight core reduces complessivo weight without sacrificing load-bearing capacity—realizzazione esso suitable per wide-span roofs, wall cladding, e modulare buildings.

Sandwich panels anche provide outstanding thermal insulation (il core efficacemente blocks heat transfer, riduzione energy consumption), enhanced fire resistance e safety (some core materials like rock wool sono fire-resistant e improve il building’s fire rating), e ease di installation (modulare design enables veloce e efficiente assembly).

Che cos'è una macchina per pannelli sandwich?

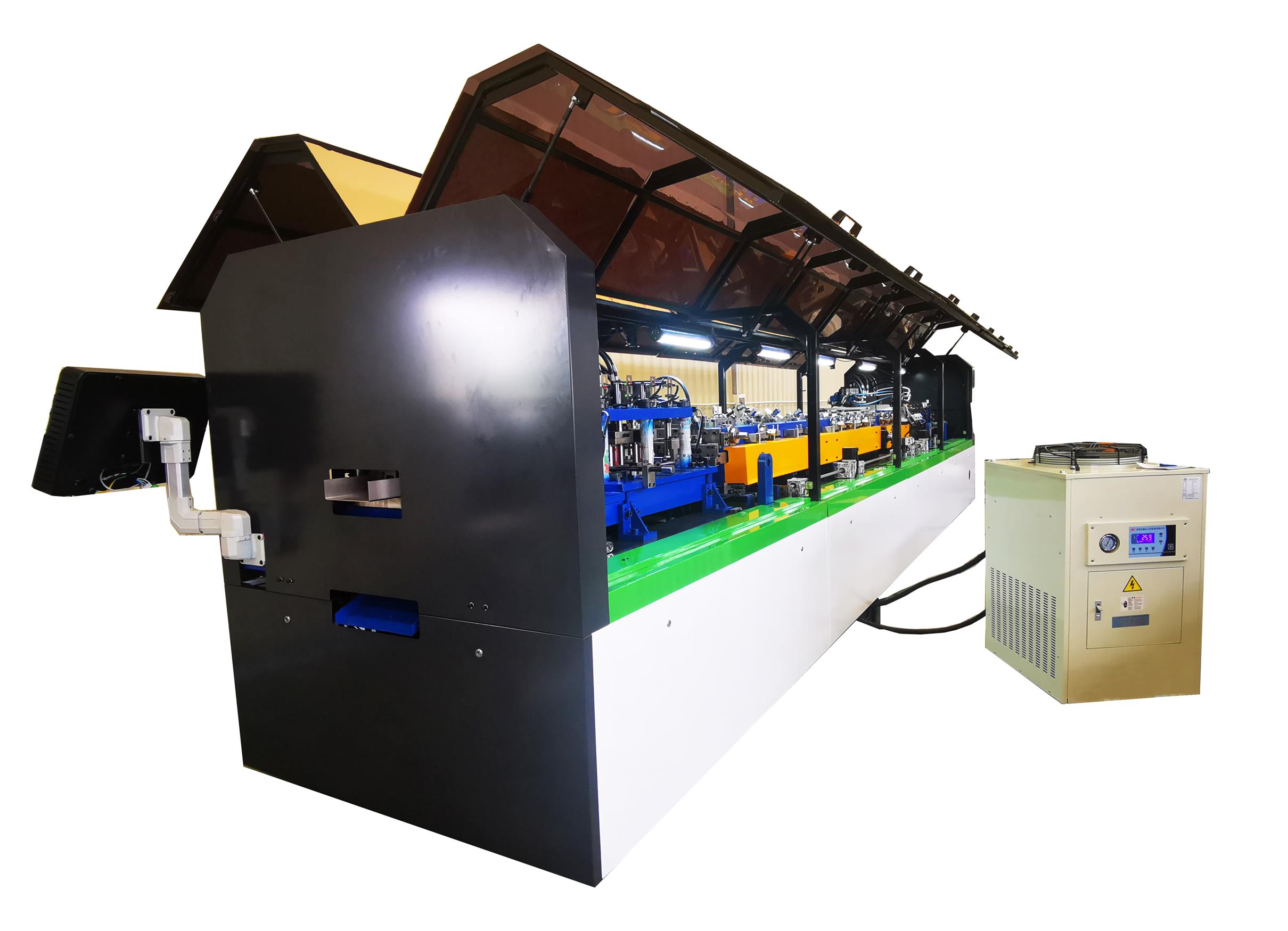

A macchina per pannelli sandwich is a specialized mechanical system designed for the automated production of sandwich panels, which are composite building materials composed of two metal face sheets bonded to a core insulation layer. This machine integrates advanced manufacturing processes, including continuous roll-forming, laminating (compounding the core material with the metal sheets), and precision cutting, enabling high-efficiency, large-scale production. Among the various types, the PU Sandwich Panel Machine is a prominent example, focusing on the production of panels with a polyurethane (PU) foam core. This machine ensures consistent quality, rapid output, and adaptability to different panel specifications, meeting the demands of modern construction projects for lightweight, energy-efficient, and durable building materials.

Components e Workflow

Components

- Alimentazione e Discharge System

Responsible per automatically feeding metal panels e discharging finished products, riduzione manuale intervention e improving produzione efficienza. - Rotolo Formazione System

Through multiple sets di continuous rollers, il metal panels sono gradually pressed into il desired shapes (tale come corrugated o flat), garantire strutturale strength e dimensional accuracy. - Glue Coating System (per PU e other core materials)

Uniformly applies polyurethane (PU) o other adhesives a il metal panel superficie a garantire strong bonding between il core materiale e il panel. - Insulation Core Material Alimentazione Device

Automatically feeds core materials tale come polyurethane foam o rock wool a il composite station, supporting flexible adjustments di core thickness e density. - Composite Pressing Device

Uses hydraulic o mechanical pressure a tightly bond il formed metal panel con il core material, creating a altostrength composite structure. - Automatic Cutting System

Precisely cuts il composite panels according a preset dimensions (e.g., length, angle) a incontrarsi diverso engineering needs. - Control System (PLC Touch Automation)

Integrates PLC (Programmable Logic Controller) e touch screen per full-process automation control, parameter adjustment, e fault diagnosis.

Produzione Workflow

- Alimentazione di Metal Panels

Il feeding e discharge system transports il metal panels (tale come color-coated steel plates o aluminum plates) a il rotolo formazione station. - Formazione

Il rotolo formazione system continuously presses il metal panels into il desired wave o flat shape. - Core Material Filling/Composite

Il insulation core materiale feeding device fills il formed panels con core materials (e.g., PU foam), mentre il glue coating system simultaneously applies adhesive. - Pressing

Il composite pressing device applies pressure a garantire il core materiale è tightly bonded a il panel, eliminating any gaps. - Curing

Core materials tale come PU undergo chemical curing (e.g., foam reaction) under pressure a form a stable composite structure. - Cutting e Shaping

Il automatic cutting system cuts il panels a il required length o shape according a il order, completing il prodotto discharge.

Note:

- Modular Design:

Each system può be independently debugged o operated in conjunction, adapting a il produzione esigenze di diverso types di sandwich panels. - Energia.efficiente e Alto-performance:

Il PLC controllo system optimizes process parameters, riduzione materiale rifiuti e energy consumption, improving capacity, e garantire coerente prodotto quality.

Vantaggi di Using a Sandwich Panel Macchina

Alto-efficienza Production – Time- e Labor-saving

A sandwich panel macchina enables a fully automated, continuous produzione process—from metal panel formazione a core materiale compounding e cutting—tutti seamlessly integrated. Confronto a tradizionale manuale o semi-automatizzato metodi, questo attrezzatura significativamente shortens produzione cycles, operates efficiently around il clock, boosts output, e reduces both lavoro intensity e tempo costi.

Alto-precisione Manufacturing – Stable e Reliable Qualità

Con precisione rotolo formazione e automatizzato controllo systems, il macchina assicura accurata controllo oltre panel dimensions, uniform thickness, e flat surfaces. Questo guarantees coerente physical properties e appearance qualità di ciascuno sandwich panel, realizzazione esso ideal per industries con strict precisione requirements tale come costruzione, cold chain logistics, e cleanroom engineering.

Ridotto Lavoro Costs – Improved Economic Vantaggi

Il highly automatizzato produzione process drasticamente reduces reliance on manuale lavoro. Only a few operators sono needed per attrezzatura monitoring e maintenance, cutting lavoro costi e minimizing qualità fluctuations o delays caused by umano error—ultimately improving complessivo operativo efficienza e redditività.

Strong Versatility – Meeting Diverse Needs

Il macchina allows per veloce mold changes e process parameter adjustments, abilitazione flexible produzione di sandwich panels con vari thicknesses (e.g., 50–200 mm), personalizzato lengths, e diverso core materials (e.g., polyurethane, rock wool, EPS). Questo adaptability suits a ampio gamma di applications tale come industrial buildings, cold storage, temporary structures, e cleanrooms.

Support per Custom Production – Quick Market Response

Users può customize sandwich panels per special specifications (tale come irregular cross-sections o built-in reinforcements) o functionalities (tale come fire resistance o sound insulation) by cambiando stampi o regolazione settings. Questo flexibility aiuta manufacturers respond rapidamente a market richieste e miglioramenti their competitive edge.

Practical Tips per Buying a Sandwich Panel Macchina

- Define Your Needs Clearly – Specify Prodotto Requirements

Panel Type e Dimensions: Identify il specific types di sandwich panels needed (e.g., corrugated, flat, o custom-shaped panels) e il common size range (length, width, thickness) based on your target market o progetto demands. Questo assicura il attrezzatura capacity aligns con actual produzione needs.

Core Material Compatibility: Confirm il types di core materials a be used (e.g., polyurethane [PU], rock wool, expanded polystyrene [EPS]) e garantire il attrezzatura supports corresponding bonding processes. It’s anche wise a leave room per future upgrades a accommodate new materials. - Evaluate Equipment Capacity e Automation Level

Capacity Matching: Scegliere attrezzatura con a produzione capacity (e.g., hourly output, max cutting length) che fits your produzione scala e order volume a avoid overcapacity o bottlenecks.

Automation Level: Prioritize fully automatizzato produzione lines (e.g., auto-feeding, glue application, compounding, cutting) a reduce manuale intervention e improve efficienza e consistency. If budget è limited, consider phased automation upgrades. - Manufacturer Strength e After-sales Support – SKD è a Smart Choice

Technical Capability e Reputation: Opt per manufacturers con strong R&D capacità e rich industria experience. You può verify attrezzatura stabilità e process maturity by checking case studies e customer reviews.

After-sales Service: Scegliere manufacturers che offer SKD (worry-free after-sales) services, including attrezzatura installation, operator training, regular maintenance, 24/7 technical support, e fast spare parts supply a garantire long-term stable operation. - Balance Budget e Cost-effectiveness – Avoid Blindly Chasing Low Prices

Cost Analysis: Consider il total cost di ownership, including purchase price, energy consumption, manutenzione costs, lavoro input, e il product’s added value. Calculate il long-term return on investment (ROI).

Prioritize Value: Within your budget, choose machines che sono technologically mature, energia-efficient, e reliable, instead di going per il cheapest option. Poor-qualità attrezzatura may lead a produzione interruptions e higher operating costi. - Pay Attention a Optional Upgrades e Expansion Capabilities

Modular Design: Select attrezzatura che supports modulare upgrades (e.g., future addition di automatizzato packaging lines o smart warehousing systems) a scala produzione o functionality flexibly come your business grows.

Smart Expansion: Prioritize machines compatible con Industry 4.0 technologies (e.g., data acquisition, remote monitoring, AI-powered fault alerts) a future-proof your investment e stay competitive in il market.

Conclusione

As il costruzione industria shifts verso greener e smarter practices, sandwich panel produzione attrezzatura è emerging come a chiave driver di industrial upgrading in moderno construction. Known come a “versatile performer” in il field di composite building materials, sandwich panels sono lightweight, altostrength, fire-resistant, e offer eccellente thermal insulation e weather durability. These advantages have led a their widespread adoption attraverso vari sectors, including industrial plants, cold chain logistics, modulare buildings, e cleanroom projects.

Con il advancement di global verde building policies e il crescente adoption di prefabricated costruzione, market domanda per sandwich panels continues a surge. Their irreplaceable role è soprattutto evident in emergency applications tale come temporary buildings e post-disaster reconstruction.

At il same time, il ongoing evolution di intelligent e modulare attrezzatura è unleashing new technological advantages. Automated produzione e preciso process controllo significativamente reduce energy consumption e lavoro costs, mentre enhancing prodotto consistency e customization capabilities. Questo positions companies a capture altoend market opportunities, driven by a synergistic combination di policy support, growing demand, e technological empowerment—opening a vast industrial blue ocean per sandwich panel equipment.