金属屋根成形機の紹介

金属屋根成形機現代建築に欠かせない重要な設備として、先進的な技術と効率的な生産能力により、建設業界の発展を促進する重要な力となっている。この設備は、高剛性、軽量、設置が簡単で耐久性のある金属屋根パネルを生産することができ、工業用ビル、農業施設、住宅などの様々な建設プロジェクトで広く使用されています。その優れた性能とユニークな利点により、今日の建設分野で極めて重要な地位を占めている。

優れた剛性:極端な天候に対する強固なバリア

金属屋根成形機によって製造される屋根パネルの最大の利点のひとつは、その優れた剛性です。これらの屋根パネルは、暴風、強風、積雪などの過酷な気象条件下でも安定した状態を保つことができ、建物の強固な防護壁となります。屋根パネルの高い剛性は、建物の安全性を高めるだけでなく、屋根の耐用年数を延ばし、長期間の使用でも建物の安定性を維持することができます。

さらに重要なことは、金属材料には自然な耐食性があり、酸性雨や紫外線などの環境要因に効果的に抵抗し、材料の老化や損傷を遅らせることができるため、屋根パネルの耐用年数を大幅に延ばし、長期的なメンテナンスコストを削減することができる。

軽量設計:建設効率の向上

金属屋根成形機のもうひとつの特長は、製造される屋根パネルが軽量であることです。この軽量設計により、建物全体の重量が大幅に軽減され、躯体への負担が軽減されるだけでなく、工事の進捗も早まります。従来の屋根材に比べ、金属屋根パネルは軽量で施工が容易なため、工期を効果的に短縮することができます。

この軽量設計は、建物の安全性を向上させるだけでなく、建設プロセスをより効率的にします。新築プロジェクトでも改修プロジェクトでも、金属屋根成形機によって生産された屋根パネルは、プロジェクトの時間と人件費を大幅に節約し、建設業界の効率化と環境保護の方向への発展を促進することができます。

簡単な設置:正確で効率的

金属屋根成形機は自動制御技術を採用し、屋根パネルのサイズと仕様を正確に制御し、各屋根パネルの生産精度が標準要求を満たすことを保証します。この精密な制御のおかげで、工事担当者は設計図面に従って、迅速かつ正確に屋根パネルの設置を完了することができ、現場の建設効率を大幅に向上させ、手動操作によるエラーを減らすことができます。

さらに、金属屋根パネルの精度は屋根の美しさも保証するため、あらゆる細部が設計要件を満たし、建物全体の品質と外観を向上させる。シンプルな施工工程と効率的な工法は、現代建築の急速な発展の基礎となっている。

超耐久性:低メンテナンスコスト

金属屋根成形機によって生産された屋根パネルは、非常に強い耐久性を持っており、市場で比類のない競争力を発揮します。これらの屋根パネルは、高品質の金属材料で作られ、絶妙な職人技で加工されています。耐風性、耐雨性、耐紫外線性に優れているだけでなく、様々な過酷な環境下で長期間使用することができます。

従来の屋根材に比べ、金属屋根パネルは頻繁なメンテナンスや交換を必要としないため、長期使用におけるメンテナンスコストを大幅に削減することができます。この超長寿命と低メンテナンスコストは、企業や家庭により経済的な選択肢を提供します。

環境保護と持続可能な開発:グリーン・ビルディングの最初の選択肢

金属屋根成形機の生産工程は効率的で低コストであるだけでなく、生産される屋根パネルは現代のグリーンビルのコンセプトに合致している。まず第一に、金属材料自体には強力なリサイクル・再利用能力があり、これは循環型経済の発展傾向に沿ったものである。第二に、金属屋根パネルの耐久性と耐食性により、使用中の頻繁なメンテナンスや交換が不要となり、資源の浪費を減らし、建設業界の持続可能な発展を促進する。

金属屋根成形機によって生産される屋根パネルは、建築物の長期的な運営コストを削減するだけでなく、資源の最適な利用を実現し、環境への負荷を軽減することができます。

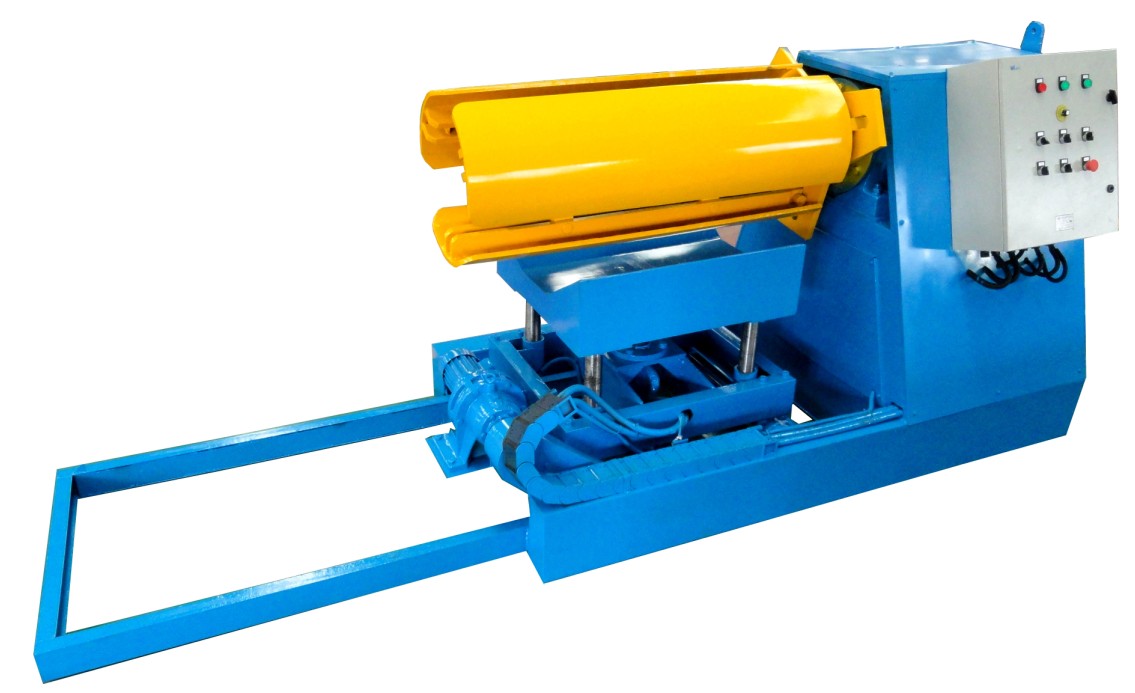

金属屋根成形機のワークフロー

金属屋根成形機の製造工程は複数のリンクで構成され、それぞれが最終製品の品質と機能性を確保するために慎重に設計されています:

- アンコイラー:原料のコイル鋼板を巻き戻し、生産ラインに入る準備をする;

- フィードガイド装置:鋼板が次のリンクに所定の方向にスムーズに送り込まれるようにする;

- プレシャーリング装置:鋼板をプレカットし、必要に応じて調整する;

- 圧延成形システム:複数のローラーを通して目標波形を成形する;

- 油圧式後剪断装置:油圧システムを通して正確に剪断し、屋根パネルのサイズを確保する;

- 排出ラック:最終的に成形されたルーフパネルを需要に応じて積み重ねる。

仕事の流れ

デコイラー→供給ガイド装置→プレカット装置→ロールフォーミングシステム→油圧ポストカット装置→排出ラック

この生産工程により、各屋根パネルの精度と安定性が保証され、屋根パネルに関する様々な建設プロジェクトの異なる要件を満たすことができる。

機械技術パラメーター

| そうだ。 | 項目 | パラメータ |

| 1 | マシンサイズ | 7200*1500*1600mm |

| 2 | 機械重量 | 5000kg |

| 3 | マシンパワー | 5.5kw |

| 4 | 油圧エンジン | 2.2kw |

| 5 | ロール速度 | 0~20m/分 |

| 6 | ロールステーション | 14 |

| 7 | ローラー素材 | 45#Sスチール |

| 8 | 有効幅 | カスタマイズ |

| 9 | 給餌幅 | 914mm |

| 10 | 電圧 | 380V 50Hz 3PH/Customized |

| 11 | 材料の厚さ | 0.35-0.65mm/Customized |

| 12 | 制御システム | シュナイダー/デルタ/カスタマイズ |

金属屋根成形機の広いアプリケーション

金属屋根成形機によって生産された屋根パネルは、建設業界で広く使用されています。金属屋根パネルは、工業プラントや倉庫などの大型建築物、住宅や農業施設などで重要な役割を果たしています。特に、高効率、環境保護、省エネルギーなどの現代建築の要求の下で、金属屋根パネルは、その軽さと耐久性のために好ましい材料となっています。

金属屋根成形機は、建設業界の技術進歩を代表するだけでなく、現代建築材料の技術革新を促進するための重要な機器でもあります。この機械が生産する屋根パネルは、高剛性、軽量、耐久性、環境保護など様々な利点があり、様々な建設プロジェクトの材料に対する高い要求を満たすことができます。技術の絶え間ない革新により、金属屋根成形機は建築物の品質を向上させ、建築コストを削減し、グリーン建築を促進する上で重要な役割を果たし続けるでしょう。