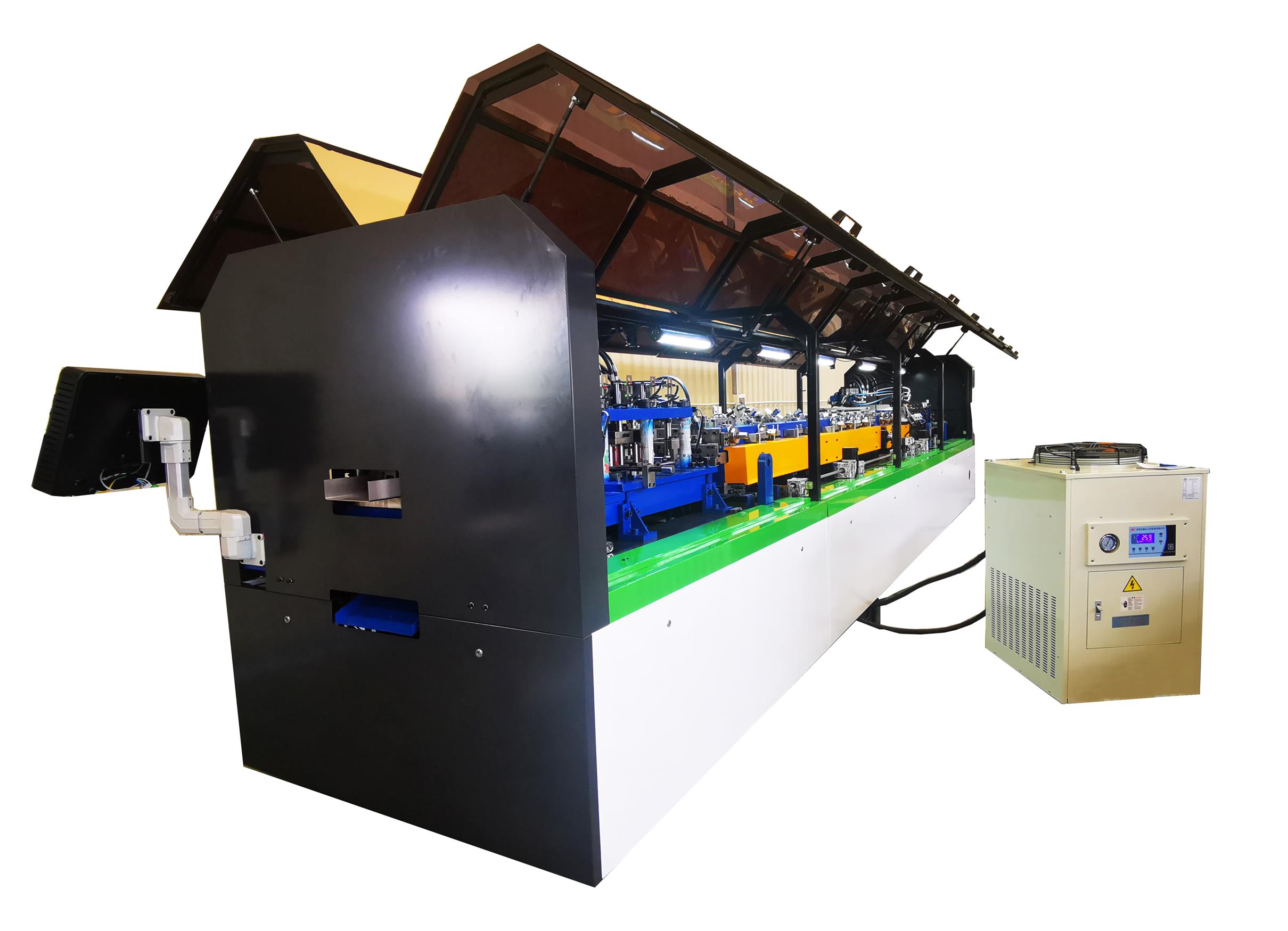

The Metal Leveling Slitting Cutting Machine is an efficient mechanical equipment that integrates leveling, striping and shearing functions, and is designed for the processing of precision metal materials. It can process various metal coils with high precision, especially in the production process of steel, aluminum alloy, copper and other materials. With its stability and high efficiency, it has become an ideal choice for many industries.

Product Introduction of Metal Leveling Slitting Cutting Machine

Our metal leveling and striping machine adopts international advanced technology, and the design fully considers the durability and efficiency of the equipment. The equipment has strong corrosion resistance and acid and alkali tolerance, which can effectively prevent the machine from rusting or oxidation during long-term use, thereby extending the service life and reducing maintenance costs.

In terms of operation, the metal leveling and striping machine has a very simple control system. Equipped with an intuitive control panel and humanized design, operators can easily get started and quickly master various operating skills. The high sensitivity of the machine enables it to achieve higher precision when cutting strips, ensuring the stable quality of each metal material.

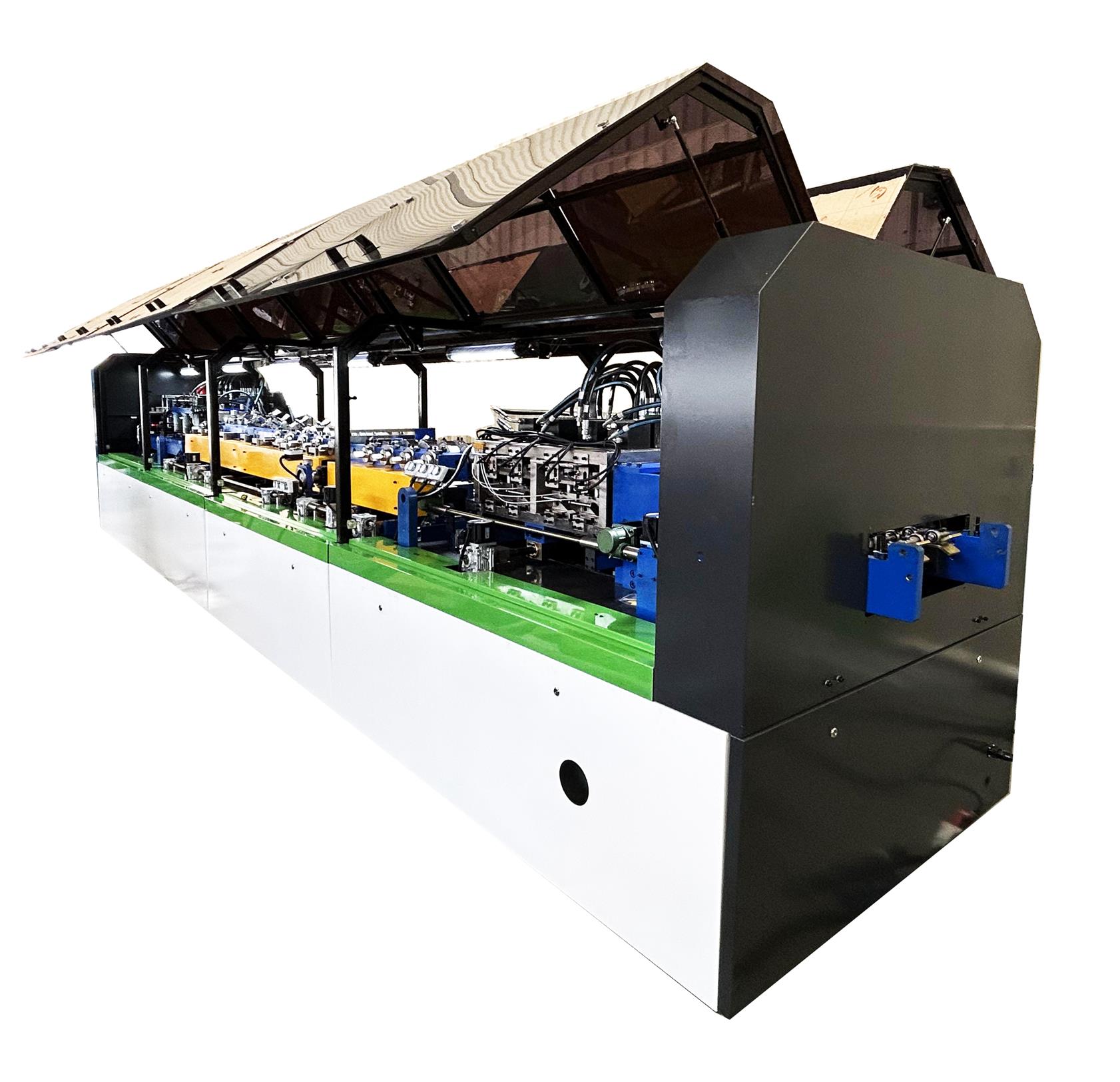

The equipment has a number of innovative technologies that further improve processing accuracy and production efficiency:

Air lift shaft: The air lift shaft can accurately adjust the winding and unwinding process of the coil, so that the coil is always in a stable state, avoiding processing errors caused by unstable materials. Through air pressure adjustment, the coil runs more smoothly in the equipment, reducing the friction of the equipment on the material, thereby avoiding scratches or damage.

Magnetic powder clutch: The magnetic powder clutch is used to adjust the tension to ensure that the material maintains precise tension control during the slitting process. This design can reduce material deformation caused by uneven tension, thereby improving cutting accuracy, reducing defective product rate, and effectively reducing material waste.

Efficient shearing function: During the slitting process, the shearing function can accurately cut metal coils according to production needs. The design of this system effectively shortens the cutting time, improves work efficiency, and ensures the quality consistency of each metal material.

Powerful power system: The machine is equipped with an efficient electric system to ensure that the equipment can maintain stable power output during long-term operation. Its stability enables the equipment to operate efficiently and adapt to large-scale, high-intensity production tasks.

Intelligent monitoring system: The equipment integrates an intelligent monitoring system, which can monitor the machine status and production progress in real time, detect potential problems in time, and ensure that the production process is not disturbed. The operator can obtain the operation data of the equipment in real time through the display screen on the control panel, and warn of potential failure risks in advance.

Metal leveling and slitting cutting machines are not only suitable for industries such as steel, automobiles, electronics, and construction, but also widely used in the processing and manufacturing of metal products. Whether it is the fine processing of thin steel plates or the high-strength processing of thick metal plates, the equipment can provide excellent performance.

Through continuous technological innovation and optimized design, this metal leveling and slitting cutting machine effectively improves production efficiency, reduces production costs, and ensures the stability of product quality. It is an ideal choice for manufacturers to increase production capacity and ensure product quality.