고속 스터드 롤 성형기는 건설 업계에서 널리 사용되는 장비로서 효율적인 생산 능력과 정밀한 성형 기술로 다양한 건설 프로젝트의 요구를 충족시키기 위해 건설 업계에서 요구하는지지 및 설치 스터드를 생산하는 데 특별히 사용됩니다.

U 프로파일 롤 성형기 매개변수

- 두께가 1.2-2.5mm인 소재에 적합합니다.

- 샤프트는 45#로 제작되었으며 정밀 가공되었습니다.

- 모터 구동, 기어 체인 구동, 성형용 롤러 16개.

- 주파수 변환 속도 조절. 성형 속도는 약 18m/min입니다.

- PLC 제어 시스템 (터치 스크린 브랜드: 독일 슈나이더 일렉트릭/대만 와인뷰,

- 인버터 브랜드: 대만 델타, 인코더 브랜드: 일본 코요/오므론)

- 핸드 휠로 위치 시계(디지털 디스플레이, 작동하기 쉬운)를 사용하여 필요한 웹, 높이 및 입술을 조정하기만 하면 됩니다,

- 그런 다음 터치스크린에 필요한 생산 데이터를 입력합니다.

- 모든 작업을 단 5~10분 만에 완료할 수 있습니다. 기존의 구식 기계처럼 롤러, 개스킷 또는 커터를 교체할 필요가 없습니다(생산 크기를 변경할 때마다 45분 이상 소요됨).

- 결합 대상 PLC, 인버터, 터치 스크린, 인코더 등

- 절단 길이 공차 ≤±2mm

- 제어 전압 24V

- 영어 사용자 설명서

U-프로파일 성형기의 주요 특징은 다음과 같습니다:

- 높은 유연성: 개스킷이나 롤러를 교체할 필요 없이 다양한 직경의 U자형 도리를 간단히 조정하고 생성함으로써 생산 효율성을 크게 높입니다.

- 다양한 도구 활용성: 다양한 크기의 U-프로파일을 수용하기 위해 공구를 계속 교체할 필요가 없으므로 가공 정밀도와 일관성을 유지하면서 공구 교체에 드는 시간과 비용을 절약할 수 있습니다.

- 간단하고 사용하기 쉽습니다: 작업자의 기술 요구 사항을 최소화하고 교육 시간과 비용을 절감하며 사용이 간편하도록 설계되었습니다.

- 낮은 유지보수 비용: 장비의 견고한 구조와 손쉬운 유지보수 덕분에 유지보수 비용이 절감되는 동시에 장비의 수명이 연장됩니다.

- 크기 맞춤 설정: 기계의 크기 범위 내에서 다양한 기술 요구 사항을 충족하도록 모든 크기의 U-프로파일을 생성할 수 있으므로 리소스를 절약하고 제조 비용을 절감할 수 있습니다.

- 펀칭 기능: 도리의 웹 쪽과 U- 프로파일의 플랜지 쪽에 어느 위치에서나 구멍을 뚫을 수 있어 나중에 조립 및 설치할 때 매우 편리합니다.

U 프로파일 롤 성형기의 프로파일 및 흐름도

스터드 및 트랙 머신의 주요 구성 요소

U-슬롯 롤 성형기 교정 섹션:

스트레이트닝 섹션은 성형 영역에 들어가기 전에 원재료가 직선 상태인지 확인하는 데 사용되며, 최종 제품의 정확성과 품질을 보장하는 데 도움이 됩니다.

U-슬롯 롤 성형기 롤러:

롤러는 성형기의 핵심 구성 요소로, 원료를 미리 정해진 U자 모양으로 압착하는 데 사용됩니다.

롤러는 고품질 베어링 스틸 GCr15 재질로 만들어졌으며, CNC 선반으로 가공하고 열처리하여 롤러의 경도와 내마모성을 보장합니다.

롤러 표면은 선택적으로 검은색으로 처리하거나 단단한 크롬으로 코팅할 수 있어 수명과 내마모성이 더욱 향상됩니다.

원재료가 롤러에 정확하고 원활하게 들어가 성형할 수 있도록 피드 가이드가 장착되어 있습니다.

본체 프레임은 400# H빔으로 용접되어 기계의 전반적인 안정성과 내구성을 보장합니다.

포밍 나이프:

성형 나이프는 스터드 또는 트랙을 정확하게 절단하고 형성하는 데 사용되는 성형 공정의 또 다른 핵심 구성 요소입니다.

이 나이프는 스터드와 트랙의 크기가 정확하고 표면이 매끄럽게 제작되도록 정밀하게 설계되었습니다.

PLC 제어 시스템(2가지 유형 사용 가능):

PLC 제어 시스템은 전체 성형 공정을 제어하는 기계의 '두뇌'와 같은 역할을 합니다.

사용자는 제어판을 통해 손쉽게 파라미터를 설정하고 작동 상태를 모니터링하며 자동화된 생산을 실현할 수 있습니다.

이 시스템은 다양한 사용자의 요구와 예산을 충족하기 위해 두 가지 옵션 구성을 제공합니다.

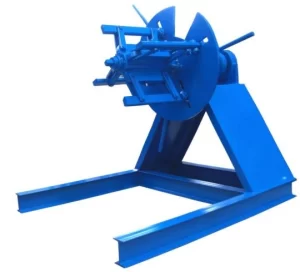

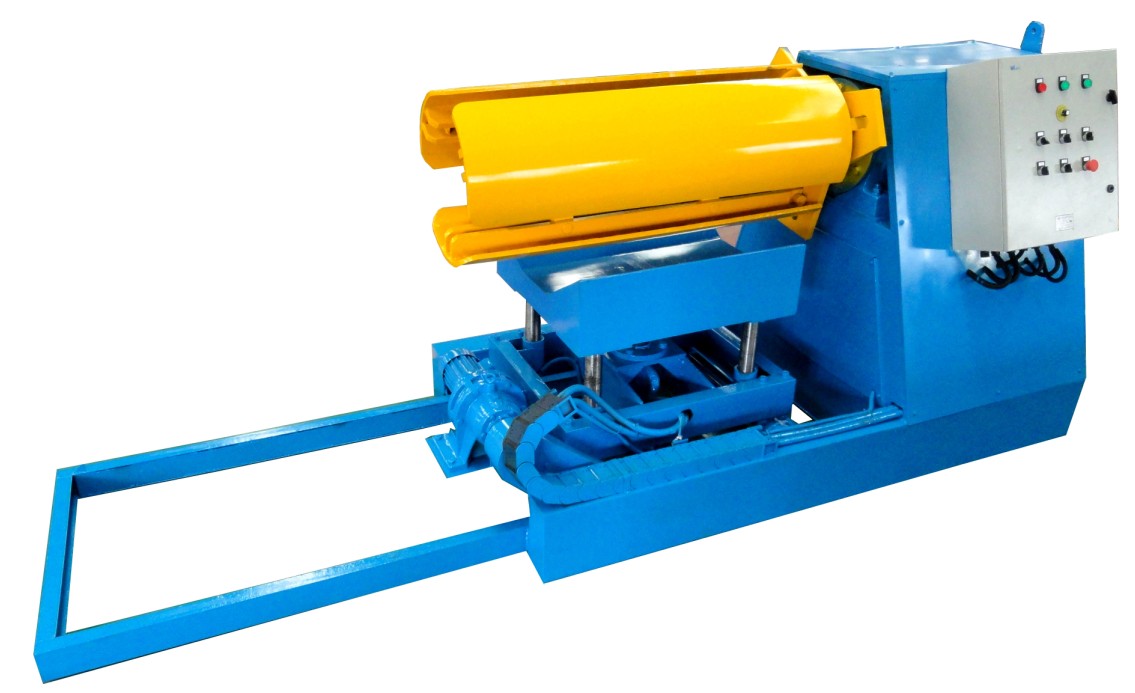

언코일러(2가지 유형 사용 가능):

언코일러는 원재료 코일을 풀고 성형기에 공급하는 데 사용됩니다.

수동 언코일러는 소규모 생산 또는 수동 조작이 필요한 경우에 적합합니다. 사용자는 수동 조작을 통해 코일의 풀림 속도와 장력을 제어할 수 있습니다.

유압 언코일러는 대규모 자동화된 생산 요구에 적합합니다. 더 높은 수준의 자동화와 더 안정적인 풀림 성능을 제공하여 코일의 부드러운 풀림과 정밀한 제어를 보장할 수 있습니다.