Stogo dengimo mašinos yra moderniausi metalinių stogų apdorojimo įrankiai, kuriais galima sukurti metalines stogo plokštes su specialiomis paslėptomis arba paslėptomis tvirtinimo sistemomis ir savaiminio užrakinimo mechanizmais. Šia pažangiausia technologija užtikrinamas stogo plokščių stabilumas, kuris taip pat gerokai padidina jų patvarumą ir patrauklumą.

Stogo dengimo mašinos su nuolatinėmis siūlėmis siūlo įvairias medžiagų alternatyvas, atitinkančias įvairių statybos projektų reikalavimus. Iš anksto dengta cinkuota plieno skarda, arba PPGI plienas, dėl didelio atsparumo atmosferos poveikiui ir korozijai naudojamas konstrukcijoms, kurios ilgą laiką turi būti veikiamos išorėje. Kitas populiarus variantas yra ZI arba GI plienas, dažnai vadinamas cinkuota geležimi arba cinkuotu plienu, nes jis pasižymi didesniu atsparumu korozijai ir yra lengviau apdorojamas.

Be to, dėl savo ypatingų savybių cinkuotas plienas ir cinko bei aliuminio lydiniai yra ypač svarbūs. Cinkuotas plienas dar labiau sustiprinamas unikaliu dengimo procesu, kuris dar labiau padidina jo atsparumą korozijai ir ilgaamžiškumą, o cinko ir aliuminio lydinys sujungia cinko ir aliuminio privalumus, pasižyminčius išskirtiniu atsparumu korozijai ir tvirtumu.

Žinoma, aliuminis taip pat yra puiki medžiaga statybų projektams, kuriuose svarbiausia yra tvirtumas ir mažas svoris. Be to, kad aliuminis yra atsparus korozijai ir itin laidus šilumai, dėl lengvos konstrukcijos sumažėja bendra pastato apkrova.

Darbo srautas ir profilis

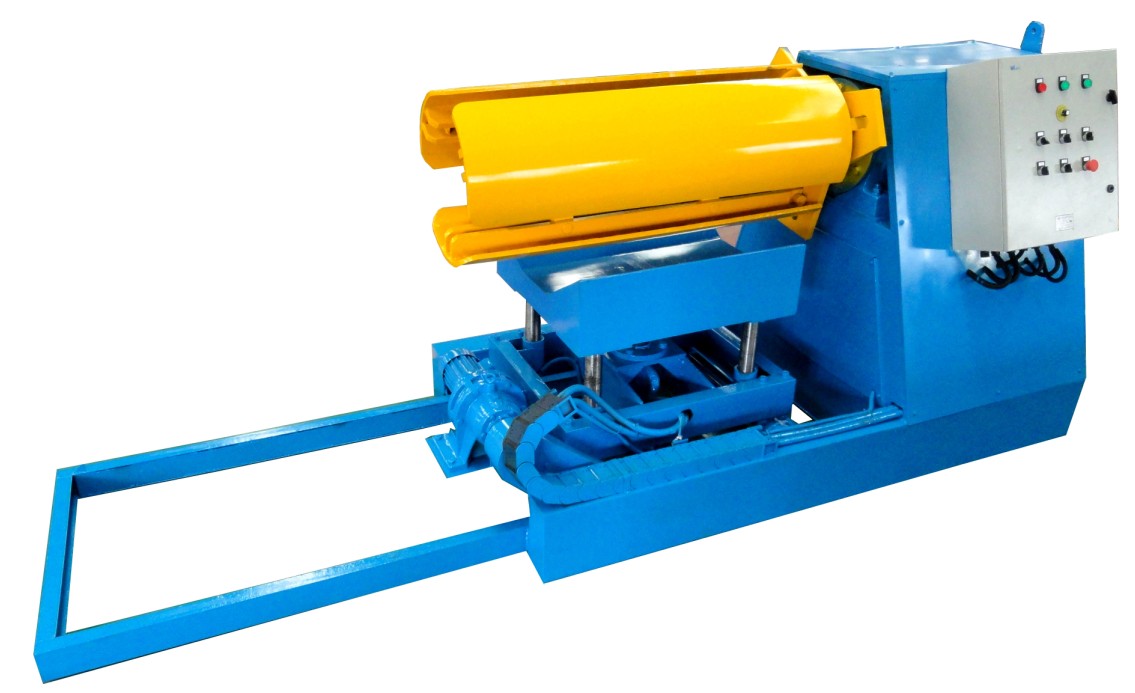

Profilio dekolonizatorius→ Rankinis išankstinis pjaustytuvas→ Padavimo kreipiamasis įtaisas→ Rulonų formavimo sistema→ Hidraulinis posto pjaustytuvas→ Išėjimo stovas

Specifikacijos

Išskirtinės užrakto jungties formos kronšteino jungiamoji plokštė yra labai lanksti ir lengvai pritaikoma įvairiuose architektūros stiliuose. Dėl šios savybės stovinčios siūlės plokštė yra puikus pasirinkimas daugybei didžiulių viešųjų erdvių, įskaitant stadionus, konferencijų sales, traukinių stotis, oro uostų terminalus ir pagrindinius transporto mazgus.

Paraiška

Stogų dengimo mašina yra specializuotas formavimo įrankis, naudojamas metalinėms plokštėms, įskaitant mangano, magnio ir aliuminio, apdoroti. Šiuo įrenginiu galima tiksliai lenkti metalo plokštes su įvairaus pločio vertikaliomis briaunomis - kartais vadinamomis "kūgiais". Dėl šio specialaus formavimo būdo statinių sienos, stogai, stoginės ir kitos konstrukcijos gaminamos įvairiais statybiniais ir dekoratyviniais tikslais, įskaitant pastatų sienų, stogų, stoglangių ir kitų konstrukcijų statybą.

Stovinčių siūlių stogų dengimo mašinose yra daugiau formų ir formavimo įrankių nei įprastose stovinčių siūlių mašinose, todėl lengviau patenkinti įvairesnių dydžių ir formų reikalavimus. Išskirtinis tikslumas, stabilumas ir efektyvumas garantuoja, kad metalo plokščių formavimo darbai bus atlikti greitai, neprarandant apdirbimo kokybės.

Be to, paprasta prižiūrėti ir eksploatuoti stogų dengimo staklėmis mašiną. Lengvai naudojama valdymo sistema ir paprasta valdymo sąsaja gerokai sumažina naudotojų sunkumus ir efektyviai sumažina darbo sąnaudas. Be to, įrangos priežiūra yra gana patogi. Paprastas derinimas ir techninė priežiūra gali greitai ištaisyti dažniausiai pasitaikančias klaidas ir problemas, todėl gerokai sumažėja techninės priežiūros laikas ir išlaidos.

Kodėl verta rinktis mūsų stogų dengimo mašiną

nepaprastas standumas ir konstrukcinės savybės

Dėl specialios mūsų stogų dengimo staklėmis mašinos konstrukcijos stogo plokštės garantuotai atlaiko vėjo slėgio deformacijas ir užtikrina tvirtą konstrukcinę atramą. Dėl naujoviško užrakto jungimo mechanizmo plokštės saugiai sujungiamos ir sukuria tvirtą stogo dangos sistemą.

Efektyvus ir mažai energijos naudojantis

Siekiant veiksmingai išvengti šalčio tilto reiškinių, padidinti šilumos izoliacijos poveikį ir atitikti energijos taupymo ir aplinkos apsaugos standartus, stovinčių siūlių stogo dangos sistemoje naudojama moderni šilumos izoliacijos konstrukcija. Dėl to pastatas ilgiau išlieka malonus ir padeda sumažinti energijos sąnaudas.

Daugybė naudojimo būdų

Mūsų stogų dengimo mašinos tinka įvairiems architektūriniams projektams ir vietoms, pavyzdžiui, stadionams, traukinių stotims, oro uostų terminalams, pagrindiniams tranzito mazgams, konferencijų ir parodų centrams ir kt. Kad ir koks sprendimas būtų reikalingas jūsų projektui, mes galime jį pasiūlyti.

Tikslumas ir techniniai privalumai

Mūsų stogų dengimo staklėmis mašina su sudėtingomis technologijomis ir plačiu formų asortimentu gali būti pritaikyta įvairioms stogo formoms ir dydžiams. Mašinos yra labai tikslios, stabilios ir efektyvios, todėl užtikrina, kad su metalo lakštų formavimu susijusios operacijos būtų atliktos kokybiškai.

Paprasta naudoti ir lengva prižiūrėti

Dėl patogios valdymo sistemos ir intuityvios valdymo sąsajos stogų dengimo staklėmis mašinos valdymas yra paprastas ir lengvai suprantamas. Kartu labai patogi įrangos priežiūra, nes dažnai pasitaikančius gedimus ir problemas galima greitai išspręsti atlikus pagrindinius derinimo ir techninės priežiūros darbus.

patikima kokybės kontrolė

Mums labiausiai rūpi patikimumas ir gaminių kokybė. Siekiant užtikrinti patikimą stogų dengimą įvairiomis sąlygomis, atliekami griežti bandymai ir kokybės kontrolės procedūros. Galite drąsiai rinktis mūsų gaminius ir naudotis ilgaamže ir tvirta stogo danga.

Aukščiausios kokybės klientų aptarnavimas

Mūsų įmonė teikia išsamią klientų aptarnavimo ir priežiūros paslaugą, kuri apima garantinį aptarnavimą, montavimo pagalbą ir technines konsultacijas. Mūsų kvalifikuoti darbuotojai padės jums greitai ir efektyviai, kad naudojimas būtų malonus.