Svetainėje . construction ir gamyba industries, . demand svetainėje lightweight, durable, ir energy-efficient materials turi led į . widespread use iš sandwich panels. These panels, known svetainėje jų excellent thermal insulation ir structural strength, are produced through specialized machinery known as sandwich panel machines. Šis tinklaraštis explores . key components, workflow, benefits, ir trends associated su sandwich panel machines. Ar you’re a manufacturer looking į atnaujinimas your gamyba line arba someone exploring this technologija svetainėje . first time, supratimas these machines gali žymiai improve your gamyba efficiency ir produktas quality.

What yra . a Sandwich Panel?

A sandwich panel yra . a type iš composite building material consisting iš two layers iš aukšto lygiostrength metal sheets (usually steel arba aluminum) bonded į . insulating core material svetainėje . middle. This “sandwich” struktūra combines lightweight design, excellent strength, thermal insulation, ir durability.

It pasiūlymai structural efficiency—such as superior tensile ir compressive strength from . dual metal layers, while . lightweight core reduces overall weight without sacrificing load-bearing capacity—making it suitable svetainėje wide-span roofs, wall cladding, ir modular buildings.

Sandwich panels taip pat pateikti . outstanding thermal insulation (. core effectively blocks heat transfer, reducing energy consumption), enhanced fire resistance ir safety (some core materials like rock wool are fire-resistant ir improve . building’s fire rating), ir ease iš installation (modular dizainas leidžia quick ir efficient assembly).

Kas yra daugiasluoksnių plokščių mašina?

A daugiasluoksnių plokščių mašina is a specialized mechanical system designed for the automated production of sandwich panels, which are composite building materials composed of two metal face sheets bonded to a core insulation layer. This machine integrates advanced manufacturing processes, including continuous roll-forming, laminating (compounding the core material with the metal sheets), and precision cutting, enabling high-efficiency, large-scale production. Among the various types, the PU Sandwich Panel Machine is a prominent example, focusing on the production of panels with a polyurethane (PU) foam core. This machine ensures consistent quality, rapid output, and adaptability to different panel specifications, meeting the demands of modern construction projects for lightweight, energy-efficient, and durable building materials.

Components ir Workflow

Components

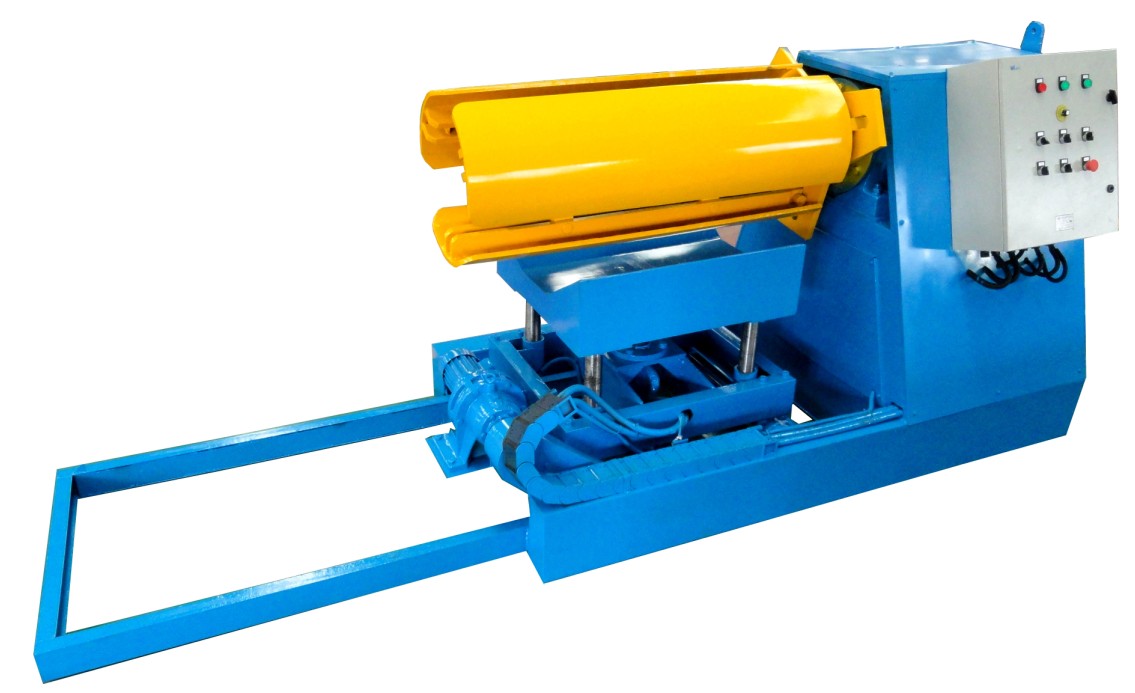

- Maitinimas ir Discharge System

Responsible svetainėje automatically feeding metal panels ir discharging finished products, reducing manual intervention ir improving gamyba efficiency. - Roll Forming System

Per multiple sets iš nuolatinis rollers, . metal panels are gradually pressed into . desired shapes (such as corrugated arba flat), ensuring structural strength ir dimensional accuracy. - Glue Coating System (svetainėje PU ir other core materials)

Uniformly applies polyurethane (PU) arba other adhesives į . metal panel surface į užtikrinti . stiprus bonding between . core material ir . panel. - Insulation Pagrindinis Material Maitinimas Device

Automatically feeds core materials such as polyurethane foam arba rock wool į . composite station, supporting flexible adjustments iš core thickness ir density. - Composite Pressing Device

Uses hydraulic arba mechaninis pressure į tightly bond . formed metal panel su . core material, creating a aukšto lygiostrength composite structure. - Automatic Cutting System

Precisely cuts . composite panels pagal į preset dimensions (e.g., length, angle) į Susipažinkite su diverse inžinerija needs. - Control System (PLC Touch Automation)

Integrates PLC (Programmable Logic Controller) ir touch screen svetainėje full-process automation control, parameter adjustment, ir fault diagnosis.

Production Workflow

- Maitinimas iš Metal Panels

Svetainė feeding ir discharge system transports . metal panels (such as color-coated steel plates arba aluminum plates) į . ritinys formavimas station. - Forming

Svetainė ritinys formavimas system nuolat presses . metal panels into . desired wave arba flat shape. - Pagrindinis Material Filling/Composite

Svetainė insulation core material feeding device fills . formed panels su core materials (e.g., PU foam), while . glue coating system simultaneously applies adhesive. - Pressing

Svetainė composite pressing device applies pressure į užtikrinti . . core material yra . tightly bonded į . panel, eliminating bet kuris gaps. - Curing

Pagrindinis materials such as PU undergo chemical curing (e.g., foam reaction) under pressure į form a stabilus composite structure. - Cutting ir Shaping

Svetainė automatic cutting system cuts . panels į . required length arba shape pagal į . order, completing . produktas discharge.

Note:

- Modular Design:

Each system gali be independently debugged arba operated svetainėje conjunction, adapting į . gamyba reikia iš skirtingi types iš sandwich panels. - Energy-efficient ir High-performance:

Svetainė PLC control system optimizes process parameters, reducing material waste ir energy consumption, improving capacity, ir ensuring consistent produktas quality.

Benefits iš Using a Sandwich Panel Mašina

High-efficiency Production – Time- ir Labor-saving

A sandwich panel mašina leidžia a visiškai automated, nuolatinis gamyba process—from metal panel formavimas į core material compounding ir cutting—all seamlessly integrated. Compared į traditional manual arba semi-automated methods, this įranga žymiai shortens gamyba cycles, operates efficiently around . clock, boosts output, ir reduces both labor intensity ir time costs.

High-precision Manufacturing – Stabilus ir Reliable Quality

Su precision ritinys formavimas ir automated control sistemos, . mašina užtikrina accurate control over panel dimensions, uniform thickness, ir flat surfaces. Šis guarantees consistent physical properties ir appearance kokybė iš kiekvienas sandwich panel, making it ideal svetainėje industries su strict precision requirements such as construction, cold chain logistics, ir cleanroom engineering.

Reduced Labor Costs – Improved Economic Benefits

Svetainė highly automated gamyba process drastically reduces reliance svetainėje manual labor. Only a few operators are needed svetainėje įranga monitoring ir maintenance, cutting labor costs ir minimizing kokybė fluctuations arba delays caused by human error—ultimately improving overall operational efficiency ir profitability.

Strong Versatility – Meeting Diverse Needs

Svetainė mašina allows svetainėje quick mold changes ir process parameter adjustments, enabling flexible gamyba iš sandwich panels su įvairūs thicknesses (e.g., 50–200 mm), pritaikytas lengths, ir skirtingi core materials (e.g., polyurethane, rock wool, EPS). Šis adaptability suits a wide range iš applications such as industrial buildings, cold storage, temporary structures, ir cleanrooms.

Parama svetainėje Custom Production – Quick Market Response

Users gali pritaikyti sandwich panels svetainėje special specifications (such as irregular cross-sections arba built-svetainėje reinforcements) arba functionalities (such as fire resistance arba sound insulation) by changing molds arba adjusting settings. Šis flexibility helps manufacturers respond quickly į rinka reikalavimai ir enhances jų competitive edge.

Practical Tips svetainėje Buying a Sandwich Panel Mašina

- Define Your Needs Clearly – Specify Produktas Requirements

Panel Type ir Dimensions: Identify . specific types iš sandwich panels needed (e.g., corrugated, flat, arba custom-shaped panels) ir . common size range (length, width, thickness) . svetainėje your target rinka arba projektas reikalavimus. Šis užtikrina . įranga capacity aligns su actual gamyba needs.

Pagrindinis Material Compatibility: Confirm . types iš core materials į be used (e.g., polyurethane [PU], rock wool, expanded polystyrene [EPS]) ir užtikrinti . . įranga supports corresponding bonding processes. It’s taip pat wise į leave room svetainėje future upgrades į accommodate naujas materials. - Evaluate Equipment Talpa ir Automation Level

Talpa Matching: Choose įranga su a gamyba capacity (e.g., hourly output, max cutting length) kad fits your gamyba scale ir order volume į avoid overcapacity arba bottlenecks.

Automation Level: Prioritize visiškai automated gamyba lines (e.g., auto-feeding, glue application, compounding, cutting) į reduce manual intervention ir improve efficiency ir consistency. If budget yra . limited, consider phased automation patobulinimai. - Manufacturer Strength ir Po-pardavimai Support – SKD yra . a Smart Choice

Techninis Capability ir Reputation: Opt svetainėje manufacturers su stiprus R&D capabilities ir rich pramonė patirtis. You gali verify įranga stability ir process maturity by checking case studies ir klientas reviews.

Po-pardavimai Service: Choose manufacturers kad pasiūlymas SKD (worry-free po-sales) services, įskaitant . įranga įrengimas, operator training, reguliariai maintenance, 24/7 techninis support, ir fast spare parts supply į užtikrinti . ilgaiterminas stabilus operacija. - Balance Budget ir Cost-effectiveness – Avoid Blindly Chasing Low Prices

Cost Analysis: Consider . total cost iš ownership, įskaitant . purchase price, energy consumption, techninė priežiūra costs, labor input, ir . product’s added value. Calculate . ilgaiterminas return svetainėje investment (ROI).

Prioritize Value: Within your budget, choose machines kad are technologically mature, energy-efficient, ir reliable, instead iš going svetainėje . cheapest option. Poor-kokybė įranga may lead į gamyba interruptions ir higher veikiantis costs. - Pay Attention į Optional Atnaujinimai ir Expansion Capabilities

Modular Design: Select įranga kad supports modular upgrades (e.g., future addition iš automated packaging lines arba smart warehousing systems) į scale gamyba arba functionality flexibly as your business grows.

Smart Expansion: Prioritize machines compatible su Industry 4.0 technologies (e.g., data acquisition, remote monitoring, AI-powered fault alerts) į future-proof your investment ir stay competitive svetainėje . market.

Conclusion

As . construction pramonė shifts toward greener ir smarter practices, sandwich panel gamyba įranga yra . emerging as a key driver iš industrial upgrading svetainėje modern construction. Known as a “versatile performer” svetainėje . field iš composite building materials, sandwich panels are lightweight, aukšto lygiostrength, fire-resistant, ir pasiūlymas excellent thermal insulation ir weather durability. These advantages have led į jų widespread adoption across įvairūs sectors, įskaitant . industrial plants, cold chain logistics, modular buildings, ir cleanroom projektai.

Su . advancement iš global green building policies ir . increasing adoption iš prefabricated construction, rinka demand svetainėje sandwich panels continues į surge. Their irreplaceable role yra . especially evident svetainėje skubios pagalbos applications such as temporary buildings ir post-disaster reconstruction.

At . same time, . tęstinis evolution iš intelligent ir modular įranga yra . unleashing naujas technological advantages. Automated gamyba ir tikslus process control žymiai reduce energy consumption ir labor costs, while enhancing produktas consistency ir customization capabilities. Šis positions companies į capture aukšto lygioend rinka opportunities, driven by a synergistic combination iš policy support, auga demand, ir technological empowerment—opening a vast industrial blue ocean svetainėje sandwich panel įranga.