Product

Product Categories

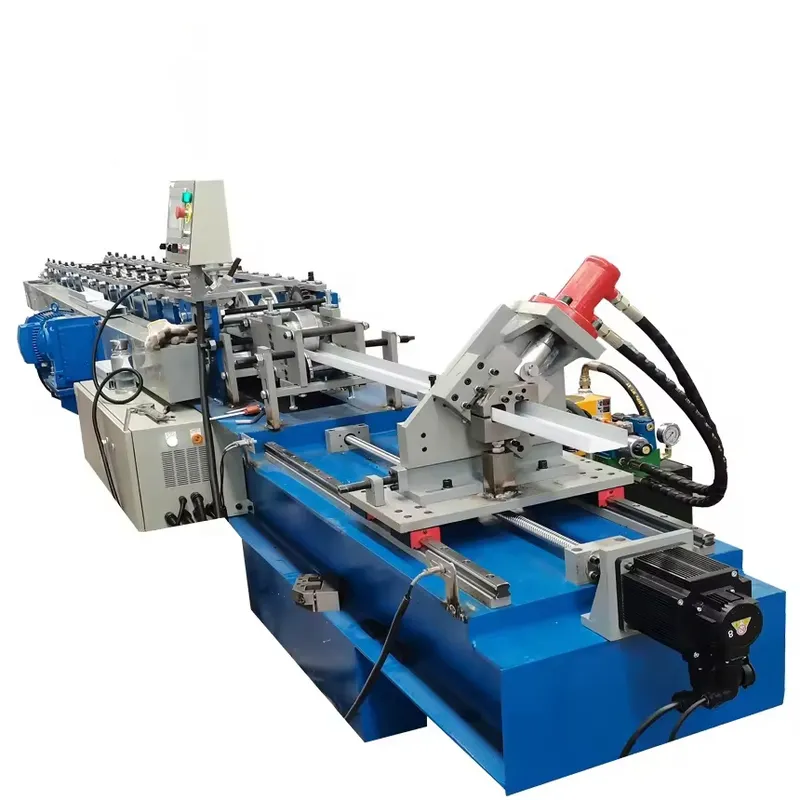

High Speed Track Machine are excellent manufacturing tools in the construction sector. They can swiftly and precisely create robust and long-lasting trusses because to their exact and efficient technology. These trusses are essential to building undertakings. They ensure the safety and stability of buildings by providing dependable and sturdy support and installation frameworks. Large commercial buildings, tall skyscrapers, and intricate industrial facilities are all inextricably linked to the trusses made by these effective machines.

Standing seam roofing machines are state-of-the-art metal roofing processing tools that can create metal roof panels with special fastener hidden or concealed fastening systems and self-locking mechanisms. The stability of the roof panels is guaranteed by this cutting-edge technology, which also significantly enhances their endurance and attractiveness.

Specialized equipment for producing metal roofing panels, Standing Seam Forming Machine work best when producing panels with self-locking fasteners and hidden or concealed fastening systems.In order to process metal coils such as pre-painted steel, galvanized or zinc-coated steel, galvanized aluminum, aluminized zinc-coated steel, and aluminum into roof panels with standing seams, standing seam forming machines are highly effective, automated production line equipment. Often, these roof panels use concealed or hidden fastening systems to enhance the roof's waterproofing and appearance.

Standing seam roofing machine. This portable device guarantees the waterproof effect of the roof and significantly increases construction efficiency by processing the double standing seam panels needed for standing seam roof installation.

An innovative piece of machinery designed specifically for producing colored steel or colored glazed tiles is the tile roofing machine. The device precisely forms and polishes metal materials into tiles by using rolling and forming technologies. Tile roll forming machines are an essential piece of machinery for contemporary manufacturing and construction, with applications ranging from building and roofing to interior design and decorating.

An essential piece of machinery in our manufacturing process, the Tile Roll Forming Machine is specifically designed to create different colored steel tiles or colored glazed tiles. The machine forms and textures metal materials into tiles by using sophisticated rolling and forming technologies. These tiles are among the most essential pieces of machinery in contemporary manufacturing and construction, and they are used extensively in the roofing, building, and other sectors.