Product

Product Categories

The sandwich panel foaming line and high-pressure polyurethane foam board machine are specialized pieces of equipment used in the construction industry that produce polyester high-pressure foam roof panels. They are known for their exceptional performance and versatility. The purpose of this manufacturing line is to make polyester foam. Using high-pressure technology, it precisely blends liquid polyester materials with other additives. Then, using a particular spraying technique, it uniformly applies the mixture to the surface that has to be filled or protected.

PU/PIR sandwich panel machine/sandwich panel production line/continuous PU sandwich panel machine is an advanced equipment specialized in the production of polyurethane (PU) foam panels. With its efficient, continuous and stable production capacity, this production line meets the market's growing demand for high-quality PU foam panels.

The insulating sandwich panel machine is an efficient production equipment specially designed for the uninterrupted manufacture of high-quality high-voltage sandwich panels. This sandwich panel is widely favored by the industry for its excellent insulation performance and durability, and is widely used in many fields such as construction, refrigeration, industrial equipment, etc.

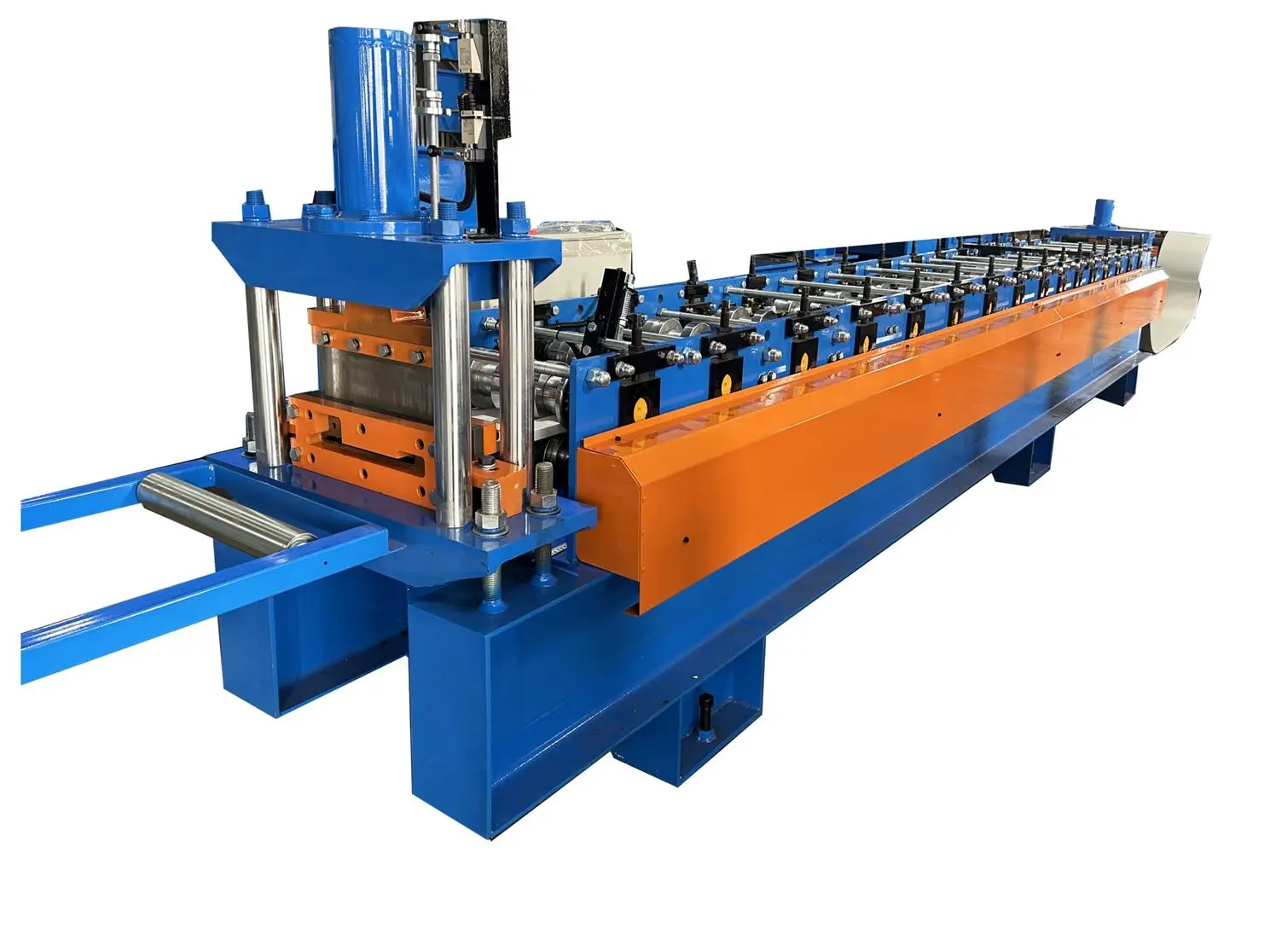

U Profile Roll Forming Machine parameters

- Suitable for materials with a thickness of 1.2-2.5mm

- The shaft is made of 45# and is precision machined

- Motor driven, gear chain driven, 16 rollers for forming.

- Frequency conversion speed regulation. Forming speed is about 18m/min

- PLC control system (touch screen brand: German Schneider Electric/Taiwan WEINVIEW,

- Inverter brand: Taiwan DELTA, encoder brand: Japan Koyo/Omron)

- Just adjust the required WEB, HEIGHT and LIP with the help of the position clock on it (with digital display, easy to operate) with the hand wheel,

- Then enter the required production data on the touch screen.

- All operations can be completed in just 5-10 minutes. No need to change rollers, gaskets or cutters like traditional old-fashioned machines (each change of production size takes more than 45 minutes).

- Combined with: PLC, inverter, touch screen, encoder, etc.

- Cutting length tolerance ≤±2 mm

- Control voltage 24V

- English user manual

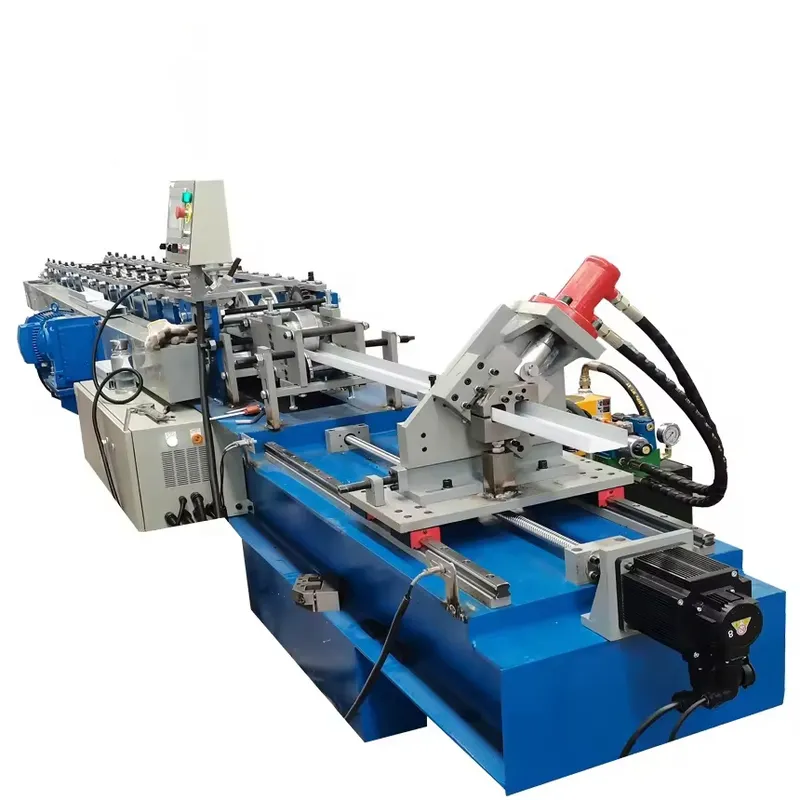

The Stud Roll Forming Machine is a special machine used to make metal studs for construction. It works by feeding metal through rollers that shape it into the right size and form. The rollers are strong and durable, ensuring smooth and accurate results. The machine is controlled by a smart system (PLC), making it easy to operate and highly automated. It comes with options for manual or hydraulic uncoilers to hold and feed the metal coils. This machine is fast, reliable, and perfect for producing high-quality studs for building projects.

The column and track roll forming machine is a versatile production equipment that can efficiently produce C-shaped columns and U-shaped tracks in the same machine. These two materials play an important supporting and installation role in the construction industry. Through roll forming technology, the machine can accurately and quickly produce columns and tracks that meet standards, providing solid and reliable basic materials for construction projects.