Floor Deck Machine Technical Parameter

| No. | Item | Parameter |

| 1 | Machine size | 11000*2200*1600mm |

| 2 | Machine weight | 11000kg |

| 3 | Machine power | 18.5kw |

| 4 | Hydraulic engine | 3.7kw |

| 5 | Roll speed | 0-18m/min |

| 6 | Roll stations | 22 |

| 7 | Roller material | 45#Steel |

| 8 | Effective width | customized |

| 9 | Feeding width | 1219mm |

| 10 | Voltage | 380V 50Hz 3PH/Customized |

| 11 | Material thickness | 0.8-1.2mm/Customized |

| 12 | Control System | Schneider/Delta/Customized |

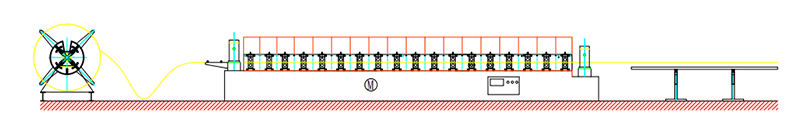

Work Flow

Decoiler→Feeding Guide Device→Pre-Cutting Device(optional)→Roll Forming System→Hydraulic Post Cutting Device→Exit Rack

Components of the machine

- Feeding

- Hydraulic pre-cutter

- Rollers of floor decking machine

Rollers are made of high-quality bearing steel GCr15, CNC lathed, heat-treated, and available with hard chrome coating.

With feeding material guide, body frame manufactured of 300# H type steel by welding

- Floor decking machine forming cutter

Made by high quality mold steel Cr12 with heat treatment

- PLC Control system

Easy to operate

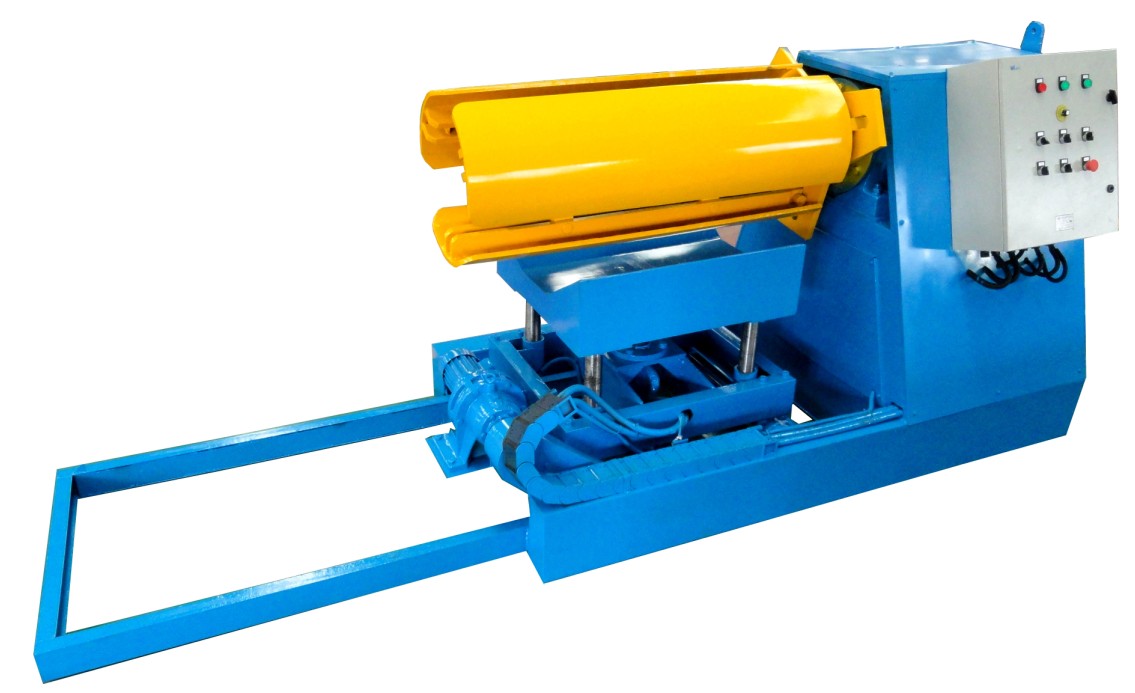

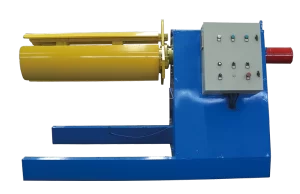

6.Decoiler

Manual Decoiler: one set

Un-powered,manually control steel coil inner bore shrinkage and stop

Max. feeding width: 1250mm, coil ID range 480mm±30mm

Capacity: Max. 5 Ton

With 5 tons hydraulic decoiler with car and without car for option

Our Services

Product Quality and Manufacturing

- Selection of Raw Materials: To guarantee the product’s strength and wear resistance, we use premium steel, such as Cr12 mold steel and GCr15 bearing steel, in the production of our metal floor slabs.

- Processing Technology: Heat treatment is utilized to enhance the material’s performance, and CNC lathes are used for precise processing. To further improve wear resistance, the roller surface is hard chrome coated.

- Strict Quality Control: To guarantee that every piece of equipment satisfies customer demands and national standards, strict quality control is implemented at every stage of the manufacturing process, from the acquisition of raw materials to assembly and commissioning.

Customized Service

Customization of Specifications: We provide a variety of models and specifications of metal floor slab roll forming machines to meet the demands of our customers.

Function Customization: We can modify certain equipment functions, including automated feeding and detection, in accordance with the production requirements of our clients.

After-sales Service

- Equipment Installation and Commissioning: To guarantee that the equipment is successfully integrated into production, provide equipment installation, commissioning, and trial operation services.

- Operation Training: To guarantee that operators are competent in the use and maintenance knowledge of the equipment, provide clients operation training.

- Repair and Maintenance: To guarantee the equipment’s long-term, steady performance, provide routine maintenance and maintenance services.

- Technical assistance: Assist clients with difficulties arising from usage by offering technical support and consulting services.