Without a doubt, high-speed track machines are excellent production tools used in the construction sector. They succeed in the building industry because to their accurate and effective technological features and outstanding performance. With their superior production capabilities, these cutting-edge tools can produce strong, long-lasting truss structures fast and precisely, providing a reliable base upon which building projects may go forward with ease.

Trusses are an essential and significant component of building projects. By offering dependable, robust support and accurate installation frameworks, they guarantee the safety and stability of structures both during construction and throughout usage. Tall skyscrapers, expansive commercial buildings, and intricate industrial facilities all rely on meticulously crafted truss structures made by high-speed rail machines for support.

Trusses that satisfy a variety of difficult requirements may be produced effectively by high-speed rail machines because to their precise control technology and sophisticated production process. These tasks satisfy the double goals of constructing beauty and functionality in addition to having outstanding bearing capacity and stability. Their presence not only raises the general standard of buildings but also gives the construction sector fresh life and momentum.

Features of Stud and Rail Machines

In the construction industry, stud and rail roll-forming machines are widely used, mainly for the production of cold-formed steel products such as studs and rails. These machines use cutting-edge roll-forming technology to efficiently roll raw materials into components with preset shapes, thereby improving production efficiency and product quality.

The Stud and Rail Roll Forming Machine consists of a motor system and several rollers. The size and shape of the product are taken into consideration when designing the rollers. The raw material is gradually deformed using continuous rolling until the final product reaches the desired shape. In addition, the machine has a precise control system that can modify variables such as roller spacing, speed and pressure to meet the needs of different products.

Profiles and flow chart of track roll forming machine

Application of track machine

“Track” simplifies the installation process of the ceiling, making the decoration more flexible and modern.

Tracks are mainly used as components for partitioning indoor spaces in buildings and are usually installed on brick walls or concrete walls. It has good load-bearing performance and rigidity, can effectively bear various loads and transfer them to the basic structure, and provides a stable support system for the building, thereby ensuring the overall safety and stability of the building.

Partition keels are mainly composed of main keels, secondary keels and vertical keels, which can be flexibly disassembled and adjusted as needed. Different materials, can be divided into many types, such as plastic partition keels and ordinary steel partition keels. Plastic partition keels are made of high-strength anti-corrosion plastic materials, with lightweight, good detachability and adjustability, suitable for internal partitions of compartments, kitchens, and bathrooms, etc.; ordinary steel partition keels are made of ordinary steel, with high load-bearing capacity, easy installation, and strong seismic performance, suitable for partitions in buildings, commercial places.

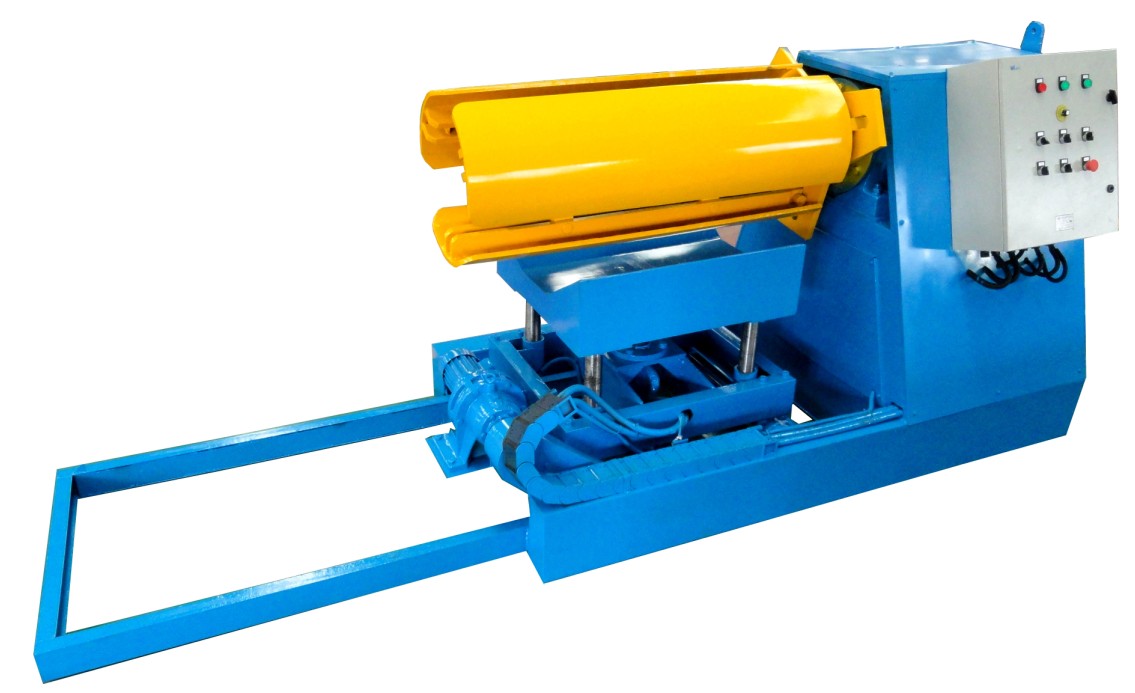

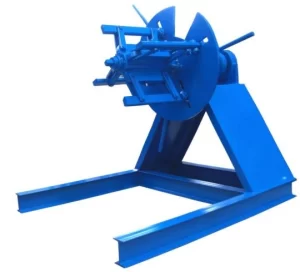

Stud track machine parts

Machine parts

1) Feeding

2) Machine roller

The roller is made of high-quality bearing steel GCr15, processed by CNC lathe, heat treated, and hard chrome plated on the surface.

3) Non-stop forming tool

4) PLC control system (2 optional)

Easy to operate

5) Uncoiler (2 optional)

1. Manual uncoiler 2. Hydraulic uncoiler

Advantages

1. Effectiveness and accuracy

construction efficiency is significantly increased by the high-speed track machine’s ability to swiftly finish the construction of trusses and other building components due to its strong manufacturing capabilities.

Precise manufacture: The high-speed track machine can guarantee that the trusses and other components produced are precise in size and stable in form, satisfying the stringent criteria of building projects for precision, thanks to sophisticated control systems and manufacturing processes.

2. Robust and long-lasting

Superior materials: High-speed track machines are often constructed from superior materials to guarantee that the trusses and other parts they create have outstanding durability and bearing capacity.

Stable performance: High-speed track machines can accurately construct trusses that have good structural stability and safety and can support buildings with dependability.

3. Adaptability and personalization

Diversified design: To satisfy the demands of several intricate building designs, high-speed track machines are able to manufacture trusses and other components in a variety of forms, sizes, and materials.

Tailored service: Offer customized services to match the best production options to the unique requirements of clients and the particulars of the project.

4. Conserving energy and safeguarding the environment

Environmentally friendly materials: In order to minimize energy consumption and environmental contamination, energy-saving and environmentally friendly materials may be used throughout the manufacturing process of high-speed track machines.

Green manufacturing is the optimization of production methods and processes along with a decrease in energy use and emissions.

5. Broad use

Construction industry: High-speed rail machines produce trusses and other components that are frequently utilized in construction projects, including skyscrapers, big commercial buildings, and intricate industrial facilities. These components provide solid assurances about the stability and safety of structures.

Other industries: High-speed rail machines may be used in rail transportation, aircraft, and other industries that need high-precision and high-strength components, in addition to the construction business.