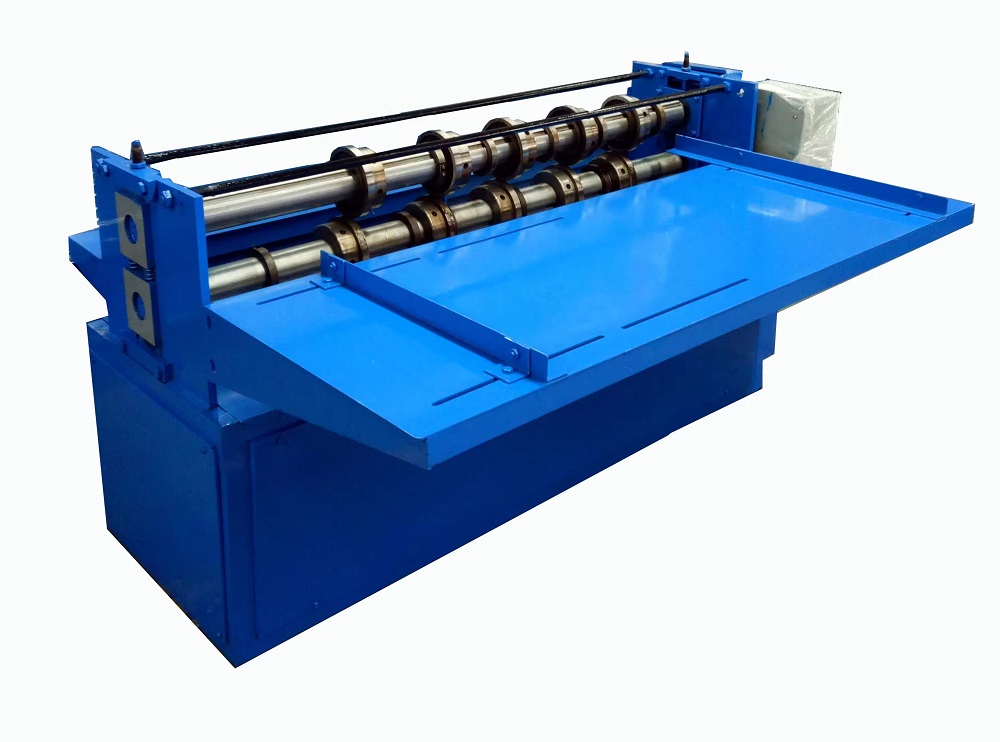

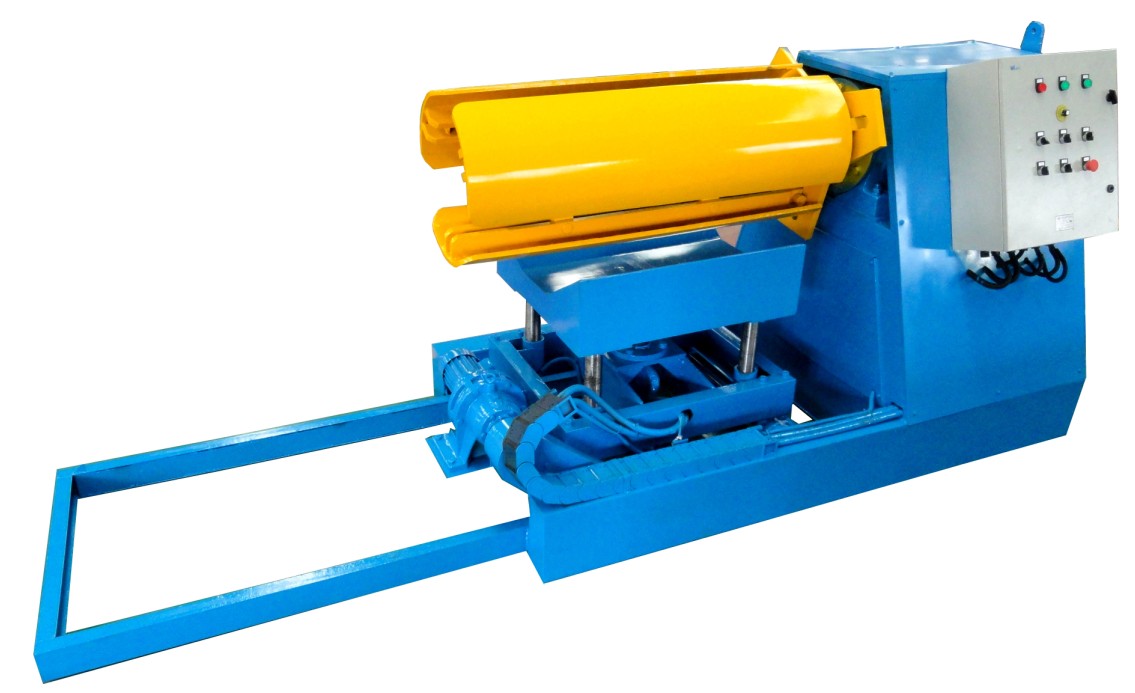

Simple Slitting Machine is a high-precision automated equipment designed for industrial material slitting needs. It is suitable for longitudinal slitting and rewinding of a variety of flexible materials. Its core technology combines ultrasonic cutting and intelligent control systems, breaking through the limitations of traditional hot knife slitting and realizing efficient, stable and environmentally friendly production processes. The equipment adopts a modular design and supports customized configuration. It can flexibly adjust the slitting width and process parameters according to the characteristics of different materials (such as cloth, non-woven fabrics, films, paper, etc.). The maximum slitting width can reach 270mm, and the production speed range is 0-30 meters/minute, meeting the diversified needs from small and medium batches to large-scale production.

Features of Simple Slitting Machine

Technological innovation, excellent quality

- Ultrasonic cutting technology: replaces traditional hot knives, avoids problems such as over-melting of materials and rough edges, and realizes precise cutting without carbonization and burrs, while reducing thermal damage and retaining the original performance of the material.

- Intelligent tension control system: through air pressure assistance and dual motor linkage, ensures that the tension of the material is stable during the slitting process, avoids stretching deformation, and improves the consistency of the finished product.

- Fast tool change and fine-tuning function: single-knife quick adjustment and knife holder precision fine-tuning design are adopted, and the slitting width adjustment accuracy reaches ±0.1mm, which greatly shortens the changeover time and improves production efficiency.

Automation and humanized design

- Full process automation: integrated automatic feeding, slitting, rewinding and waste collection functions, reducing manual intervention, reducing operation difficulty and labor intensity.

- Intelligent detection and safety protection: equipped with automatic shutdown, overload protection and fault warning system to ensure production safety and reduce scrap rate.

- Imported core components: key components (such as ultrasonic generators and servo motors) are selected from internationally renowned brands to ensure long-term and stable operation of the equipment.

Environmental protection and energy saving

- Low energy consumption design: the whole machine power is only 2.6kW, which saves more than 30% energy compared with traditional equipment, in line with the trend of green production.

- No exhaust gas emissions: ultrasonic cold cutting technology avoids harmful gases generated by high temperature and improves the workshop environment.

Specification of Simple Slitting Machine

| Cutting Width (mm) | 100 – 1300 mm |

| Dimension(L*W*H) | 1400*1400*1200mm |

| Material Thickness(mm) | 0.3 – 1 mm |

| Voltage | 380V/50HZ/3PH(accept customized) |

| No. of Slitting Cutter | 2-4 |

| Capacity | 2.2Kw |

| Video outgoing-inspection | Provided |

| Warranty | 1 Year |

Application of Simple Slitting Machine

Simple Slitting Machine is widely used in the following industries due to its flexibility and high precision:

- Textile and clothing: slitting and edge banding of materials such as trademarks, woven labels, linings, and interlinings.

- Medical and health: aseptic slitting of medical materials such as gauze, non-woven masks, and surgical gowns.

- Packaging and printing: customized slitting of packaging materials such as films, self-adhesive labels, and release paper.

- Electronics and new energy: precision slitting of lithium battery separators and insulating materials to meet the high-specification requirements of electronic components.

- Industrial manufacturing: slitting and rewinding of industrial materials such as industrial fabrics, rubber films, and composite materials.

Why choose us?

Technical strength and customized services

The company has more than 20 years of experience in the research and development of ultrasonic equipment, masters core patented technologies, and can provide non-standard customized solutions according to customer needs, providing full support from material property analysis to equipment commissioning.

Quality Assurance and Certification System

Passed ISO 9001 quality management system and CE safety certification, strictly implemented 6 major quality inspection processes (design, procurement, production, testing, installation, after-sales), to ensure that each device meets international standards.

Perfect after-sales service

- Lifelong maintenance: 1 year free warranty for the whole machine, lifelong technical support, and the consumables cost is lower than the industry average.

- 24-hour response: domestic customers will be provided with door-to-door service within 24 hours, and overseas customers will be provided with solutions within 48 hours.

- Free technical training: provide operation training and process optimization guidance to help customers quickly master equipment performance.

Industry reputation and cases

Serving 500+ customers worldwide, including well-known textile companies, medical groups, and electronic manufacturers, the equipment is exported to Europe, America, Southeast Asia, and other regions, and the market return rate is less than 1%.

Simple Slitting Machine takes technological innovation as its core and customer demand as its orientation, and is committed to becoming a benchmark product in the field of industrial material slitting. Whether it is to improve production efficiency, optimize product quality, or reduce energy consumption and costs, we will provide you with professional and reliable solutions to help your company achieve sustainable development.