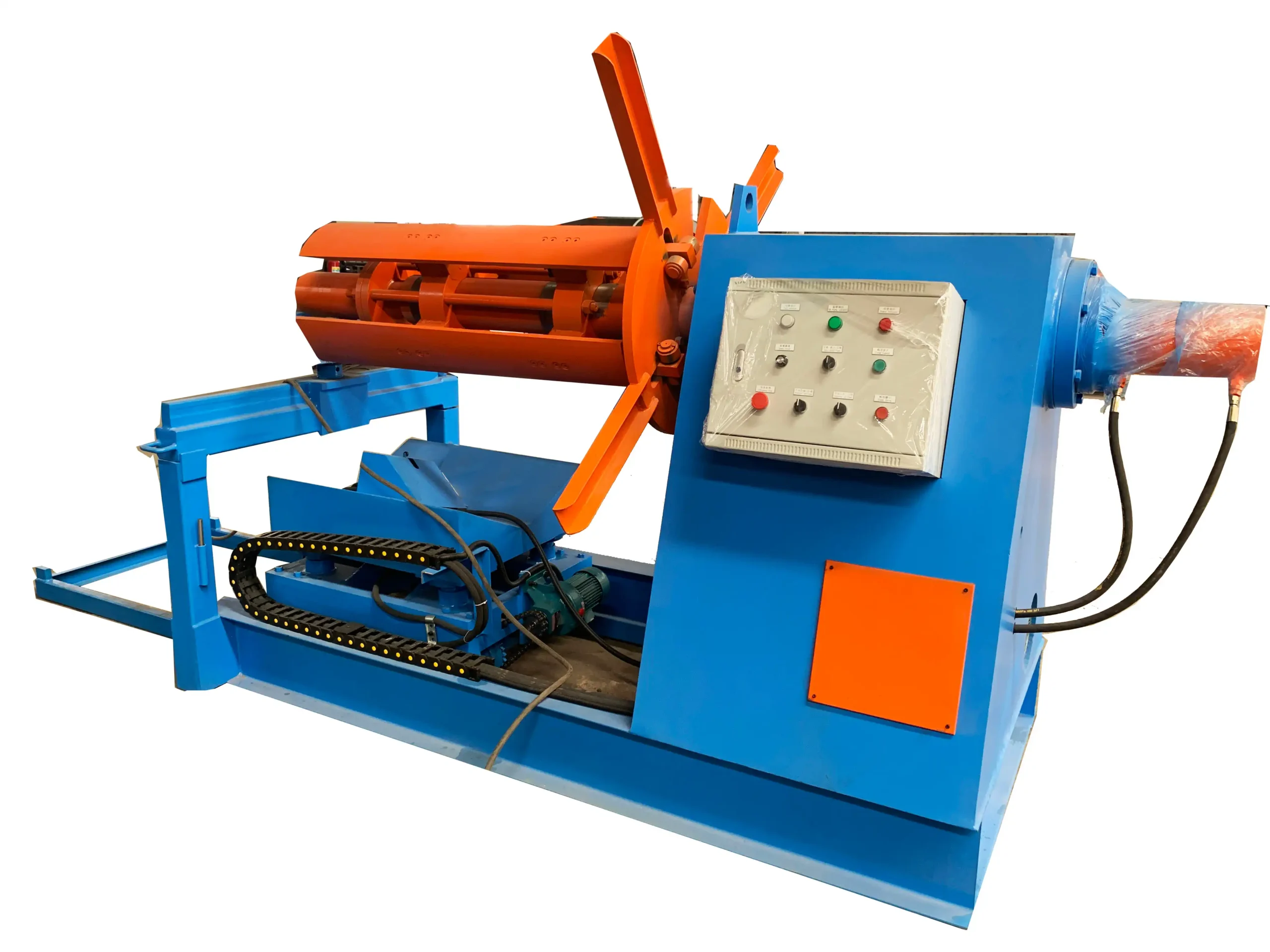

The stud roll forming machine is a specialized piece of equipment designed for the construction industry, specifically used for manufacturing installation and support studs. It features high-speed production capabilities that meet the industry’s demand for rapid manufacturing, allowing for efficient and quick roll forming of studs. Utilizing advanced roll forming technology, the machine ensures precise shaping and accurate control over the dimensions and profiles of the studs, guaranteeing full compliance with application guidelines and industry standards. A key highlight of this equipment is its high degree of automation—most modern models are equipped with sophisticated control systems and automated tools that handle processes such as loading, forming, and unloading with minimal manual intervention. This not only increases productivity but also ensures consistent quality across all output.

Stud Roll Forming Machine application:

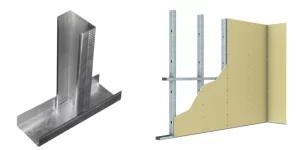

- Building sector: The primary function of high-speed stud rolling forming machines is to manufacture installation and support studs needed by the construction sector, such as those used in scaffolding, steel constructions, formwork supports, and other applications.

- Other industries: This kind of equipment may be used in industries like machinery manufacture and the production of automobile components, among others, that need for precision stud formation, in addition to the construction sector.

Characteristics

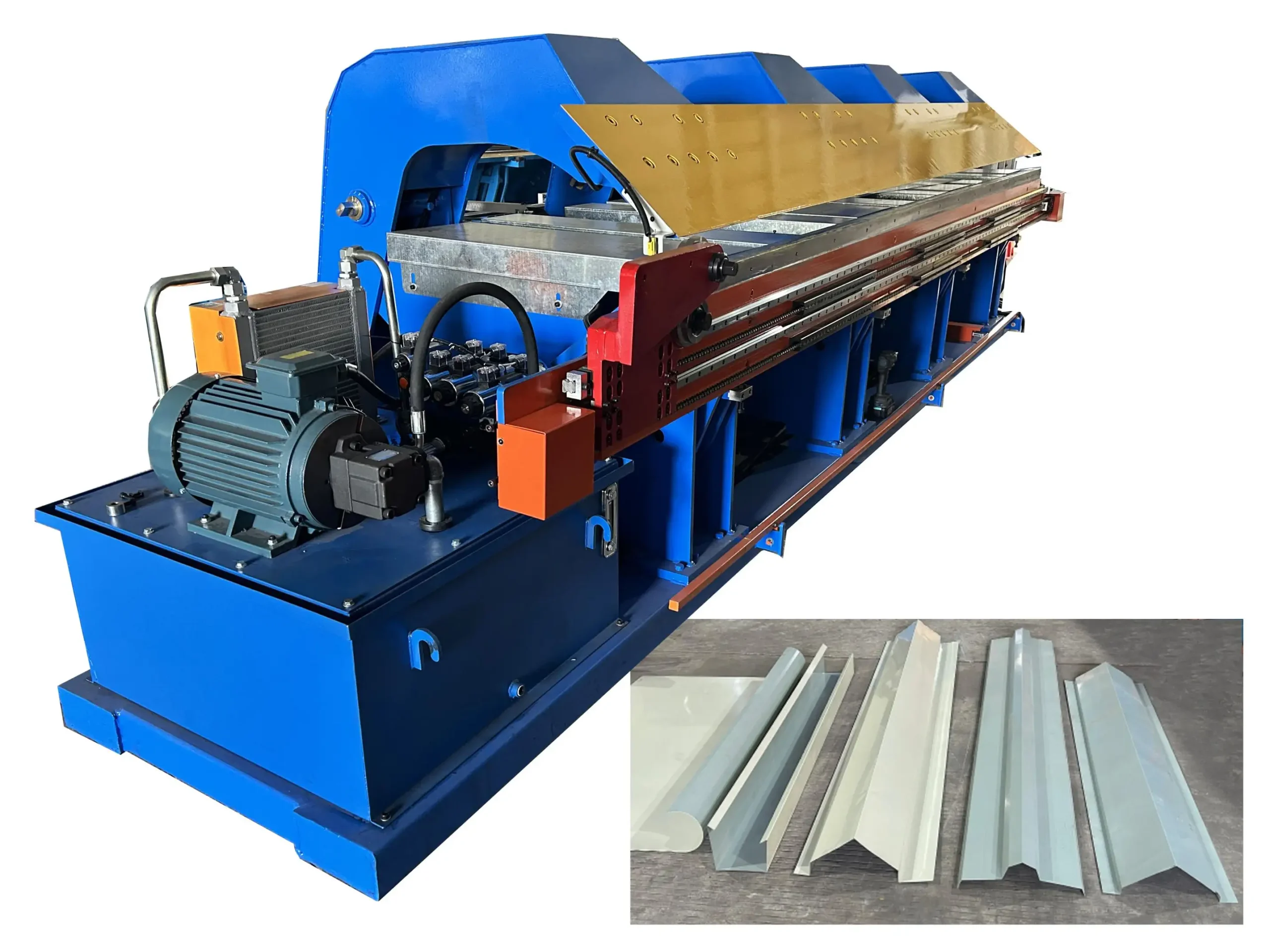

Light steel keels may be produced using the column forming machine to suit a variety of requirements. It may be used to construct factories, light houses, villas, and other structures as part of the building structure. Because of its strong strength and low weight, the building structure is more earthquake-resistant and solid. Its quick construction also helps to significantly reduce the time needed for construction. Furthermore, light steel keels may be coupled with other construction materials, including concrete and brick walls, to create a composite structure that will increase its total wind resistance and bearing capacity.

The column forming machine’s light steel columns are crucial for external wall ornamentation. They may be installed with curtain walls, stone veneers, outside wall insulation systems, and other materials. They can also serve as the supporting framework for exterior wall decorative materials. The light steel keel’s strength and low weight may lessen the strain on the building’s structural integrity while strengthening and enhancing the outside wall décor. Simultaneously, its high malleability and versatility allow it to meet a wide range of modeling specifications and architectural aesthetics, enhancing the building’s expressiveness and originality.

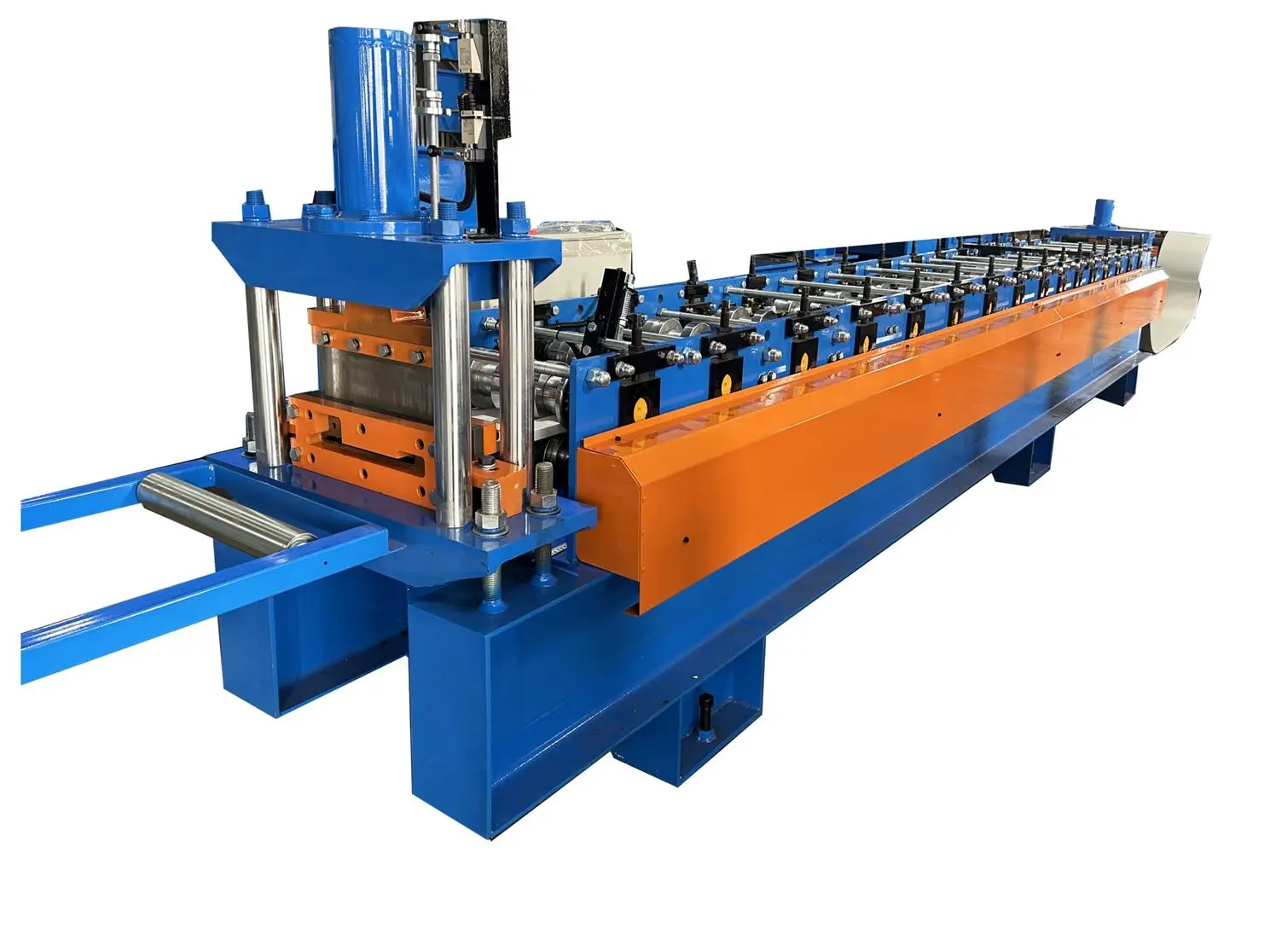

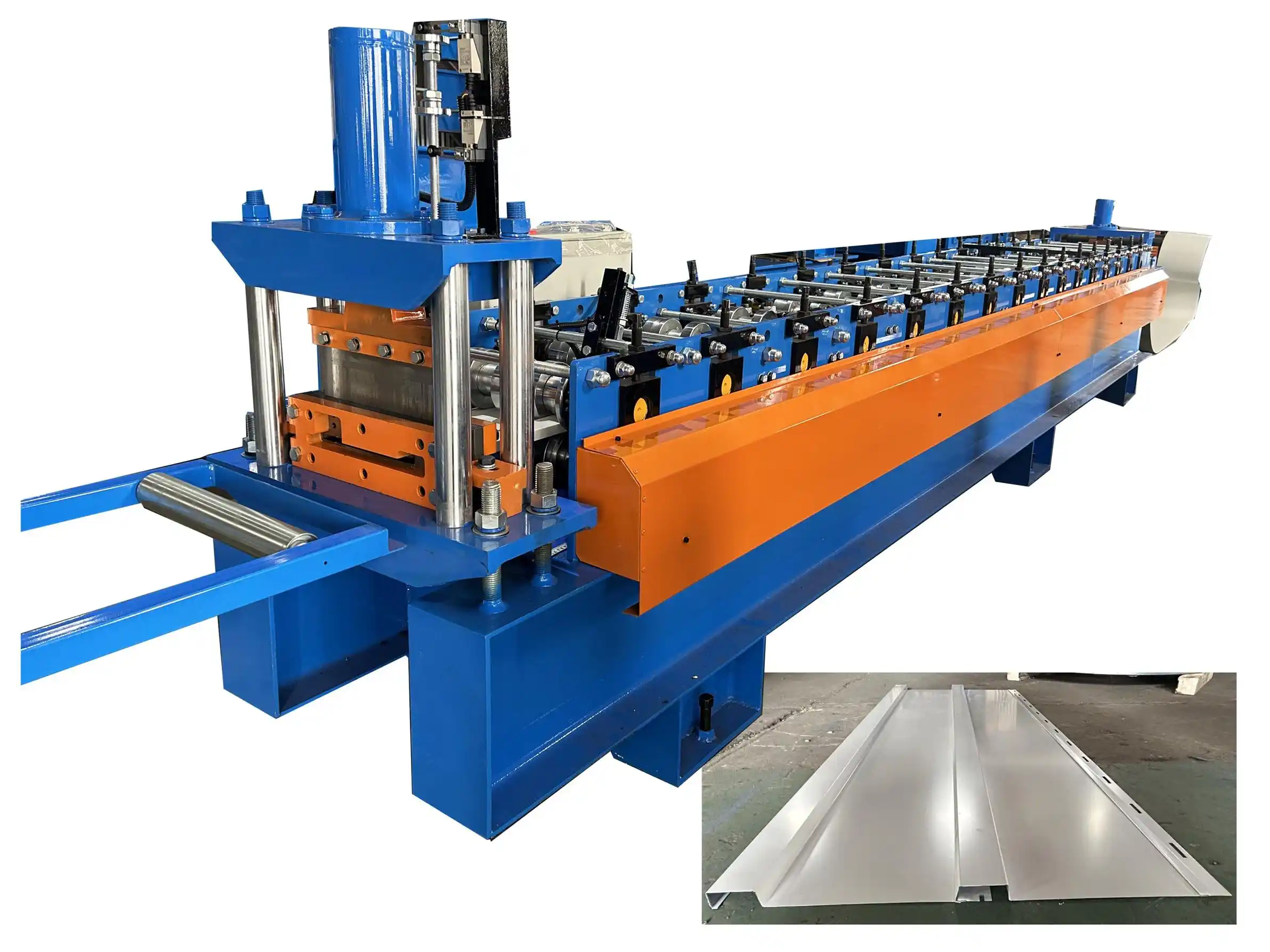

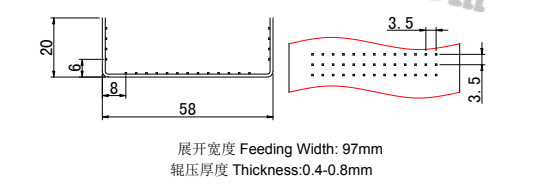

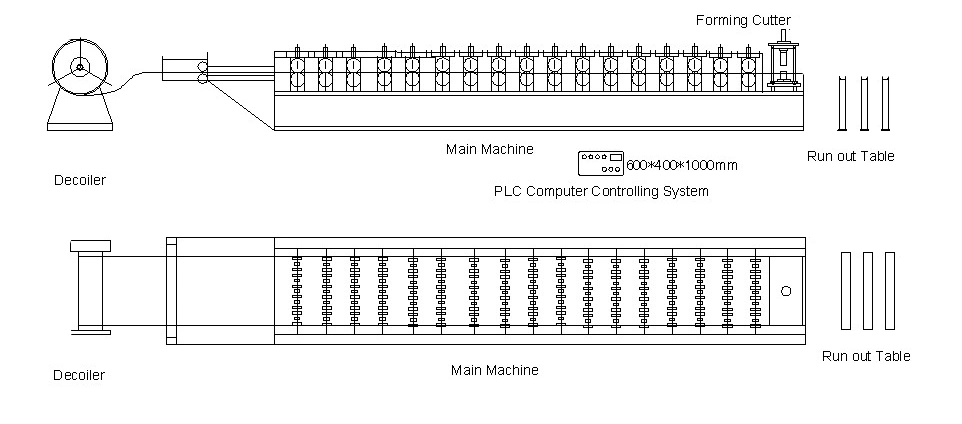

Profiles and flow chart of track roll forming machine

Why Choose SKD’s High-Speed Stud Roll Forming Machine

- High Production Efficiency: SKD’s high-speed stud roll forming machine stands out for its exceptional production speed, enabling rapid and large-scale stud output that significantly enhances manufacturing efficiency. In the construction industry, time equals profitability. By shortening the production cycle, this equipment helps ensure on-time project delivery and effectively avoids the additional costs associated with project delays.

- Significantly Reduced Labor Costs: Traditional stud manufacturing involves labor-intensive processes such as cutting, shaping, and polishing, which require substantial manual effort and incur high labor costs. The high-speed stud roll forming machine automates these processes, drastically reducing the need for manual labor. Its high precision and efficiency also minimize material waste and human error, further increasing cost-effectiveness.

- Outstanding Product Quality and Consistency: Equipped with advanced roll forming technology, this machine precisely controls the size, shape, and surface quality of each stud. Adjustable parameters allow for the production of studs that meet a wide range of standards and specifications, ensuring exceptional product reliability and uniformity. In construction, the precision and stability of studs directly affect the overall safety and structural integrity of the building, making this feature especially crucial.

- High Adaptability: The high-speed stud roll forming machine offers excellent flexibility, easily accommodating various stud models and specifications. By changing molds or adjusting settings, it can quickly switch to producing different sizes and shapes of studs, meeting diverse project demands with great practicality and efficiency.

- Energy-Efficient and Eco-Friendly: Compared to traditional manufacturing methods, this machine is more energy-efficient and generates less waste. By optimizing production processes and reducing material loss, it minimizes environmental impact, aligning with the construction industry’s current trend toward sustainable and green development.

- Easy Maintenance and Operation: The machine’s modular design makes maintenance straightforward and efficient. With high durability and operational stability, it runs reliably over long periods with reduced needs for frequent maintenance and part replacement. This improves the machine’s economic value and utilization rate, while lowering maintenance costs and downtime.

Component of stud and track machine

Feeding system:

Introduce raw materials into the machine smoothly and continuously for processing.

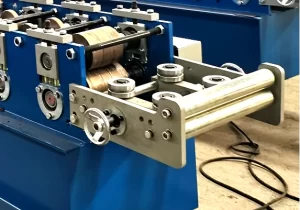

Roller:

Core component, made of high-quality bearing steel GCr15, with hard chrome plating on the surface to ensure wear resistance and high precision.

Forming tool:

Cutting and forming in the continuous production process without stopping, improving production efficiency.

PLC control system:

Easy to operate, powerful functions, realize automated production, and there are two configurations to choose from.

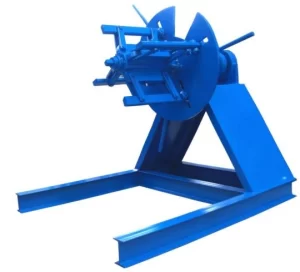

Unwinder:

Manual unwinder: suitable for small-scale or manual operation.

Hydraulic unwinder: suitable for large-scale, automated production, stable and precise.