An innovative piece of machinery designed specifically for producing colored steel or colored glazed tiles is the tile roofing machine. The device precisely forms and polishes metal materials into tiles by using rolling and forming technologies. Tile roll forming machines are an essential piece of machinery for contemporary manufacturing and construction, with applications ranging from building and roofing to interior design and decorating.

Core Features of the Tile Forming Machine:

High Efficiency Through Advanced Mechanism: Leveraging a sophisticated mechanical structure and transmission system, the tile forming machine enables rapid and continuous production, significantly boosting productivity.

Highly Adaptable and Versatile: This equipment can produce tiles in various sizes, patterns, and textures, precisely meeting the personalized needs of different architectural and design projects.

Durable and Stable Performance: Built with high-quality components and cutting-edge manufacturing techniques, the tile forming machine ensures stable operation and an exceptionally long service life.

Outstanding Safety and Reliability: Designed with comprehensive safety measures in mind, including emergency stop buttons and robust safety protection systems, the machine offers a secure and dependable user experience.

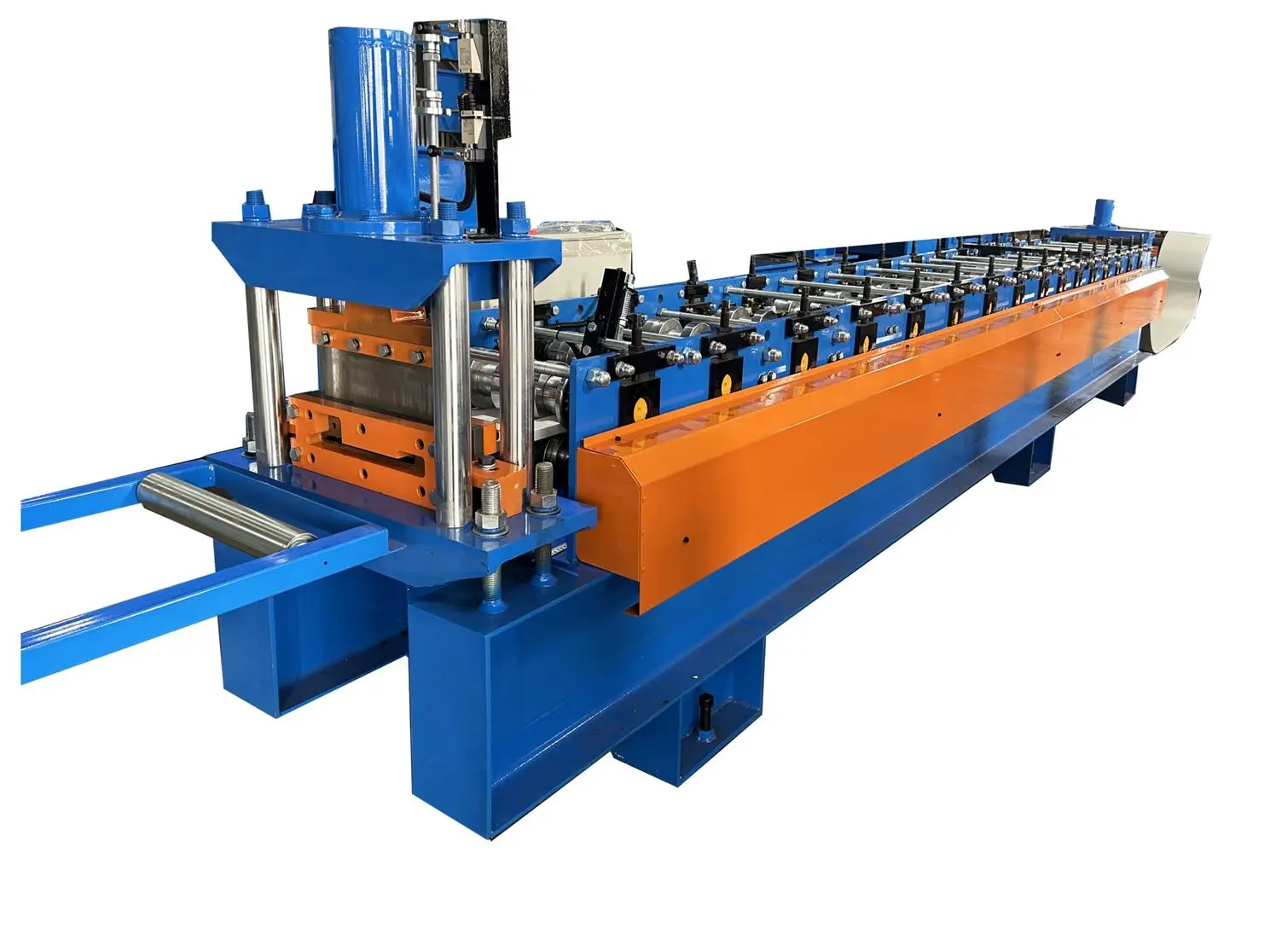

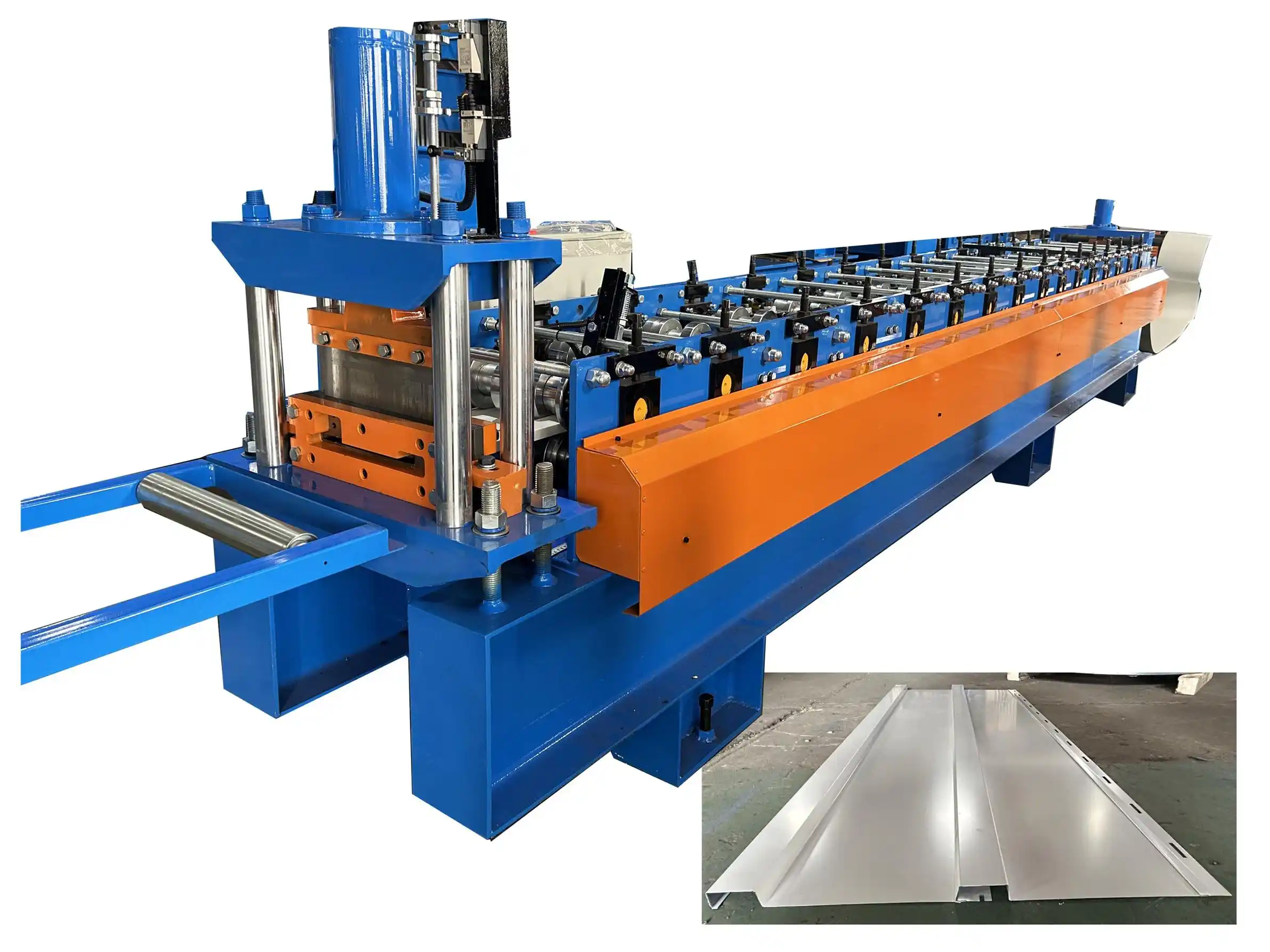

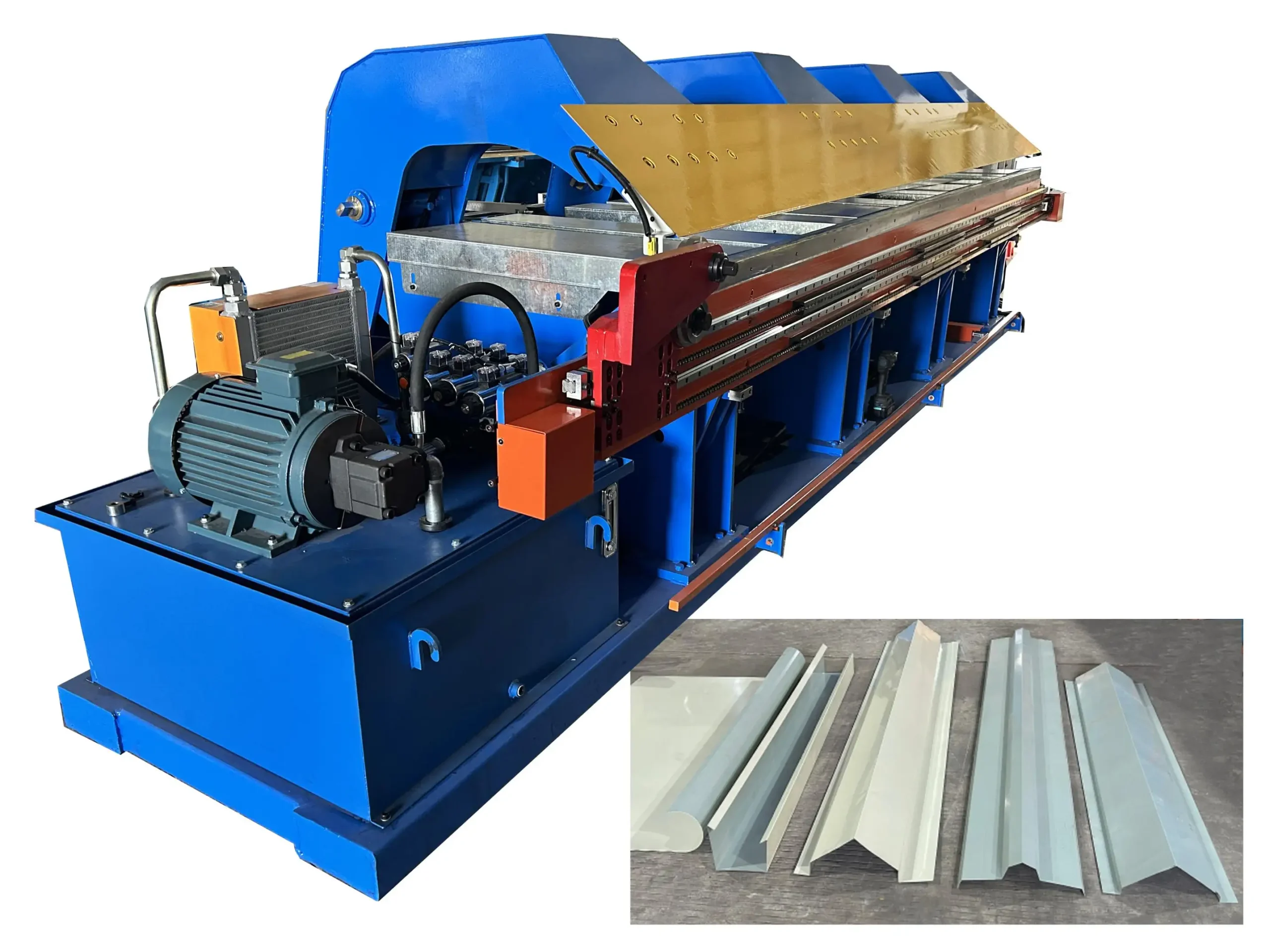

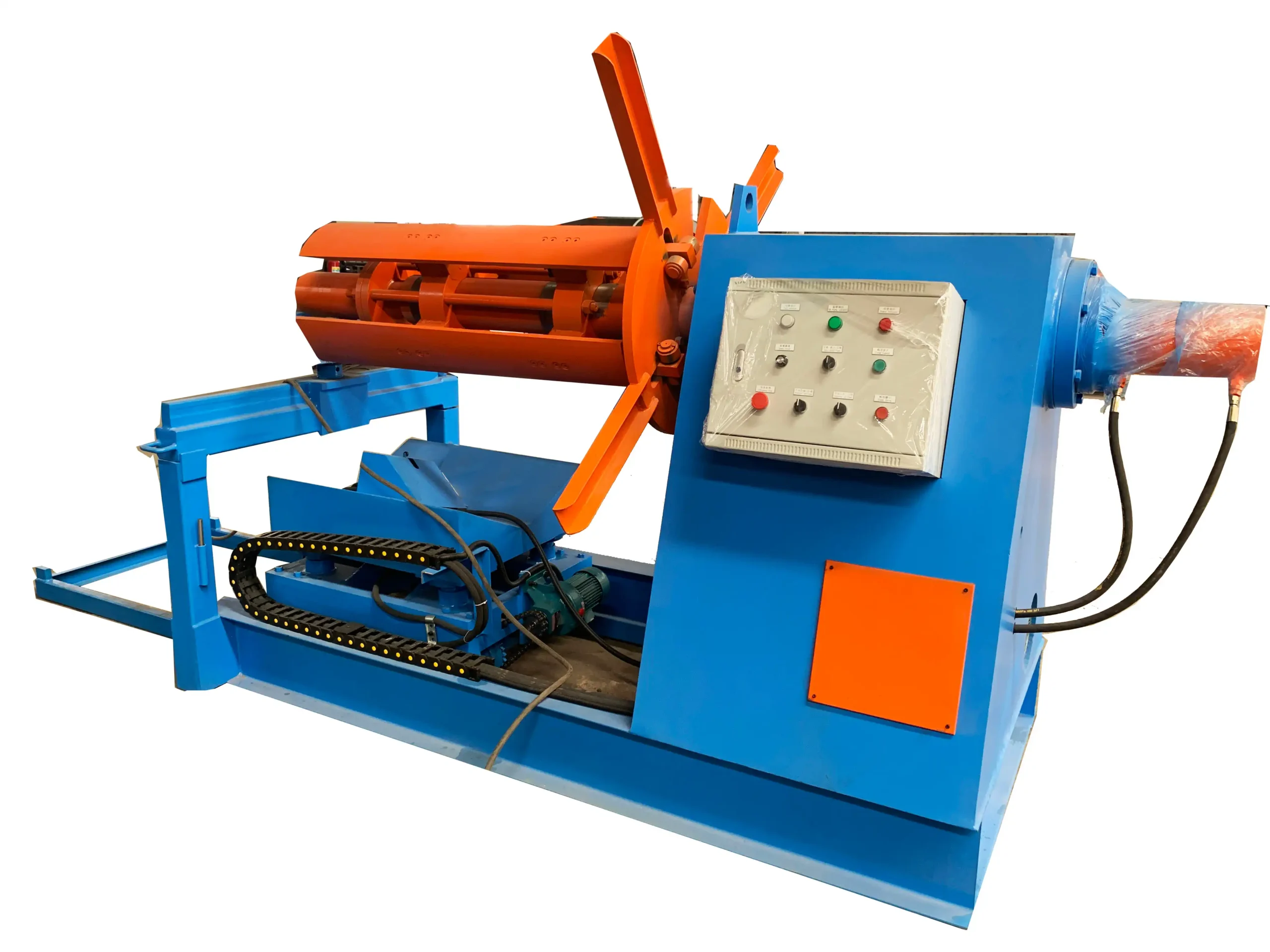

Detailed Images of tile roll forming machine

Machine Parts

1) tile roll forming machine with pre-cutter

2) tile roll forming machine rollers

Rollers are made of high-quality bearing steel GCr15, CNC lathed, heat-treated, and available with hard chrome coating.

With feeding material guide, body frame manufactured of 300# H type steel by welding.

3) Tile roll forming machine post cutter

Made by high quality mold steel Cr12 with heat treatment

Hydraulic motor:5.5KW, Hydraulic pressure range: 0-16Mpa

4)PLC Control system

Easy to operate

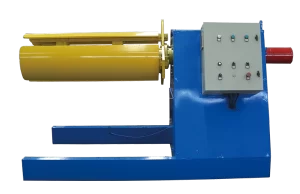

5) Double layer roof panel machine decoiler

Manual Decoiler: one set

Un-powered,manually control steel coil inner bore shrinkage and stop

Max. feeding width: 1250mm, coil ID range 480mm±30mm

Capacity: Max. 5 Ton

With 5 tons hydraulic decoiler with car and without car for option

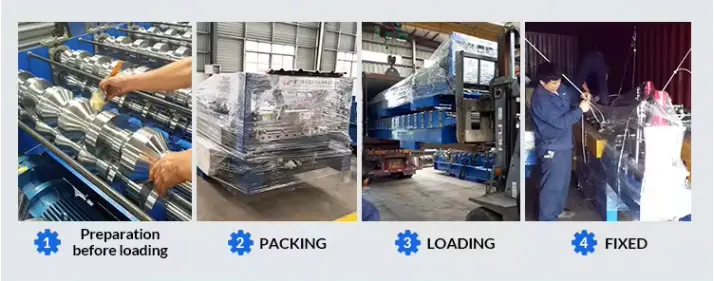

Our Services

Professional Experience

With extensive industry knowledge and expertise, our team of professionals provides clients with comprehensive technical consultations and tailored recommendations for tile roll forming machine solutions. We customize the optimal equipment configuration and production schedule based on a thorough understanding of each client’s needs and budget.Tailored Design

We offer fully customized solutions, recognizing that every project has unique requirements. Whether it’s tile size, shape, color, or finish, we design and manufacture tiles according to the client’s exact specifications to ensure the final product meets project demands precisely.Installation and Commissioning

Our engineering team handles on-site installation and commissioning of the equipment. With years of hands-on experience and strong technical skills, they ensure precise setup and stable operation. During installation, we also provide detailed operating instructions and training to ensure clients can operate the equipment confidently.After-Sales Maintenance

We value long-term partnerships with our clients, which is why we offer comprehensive after-sales maintenance services. Our technical team conducts regular visits to provide guidance on equipment operation and essential maintenance. In addition, we offer 24/7 online customer support to address any questions or concerns at any time.Technical Support and Upgrades

To keep pace with evolving technology and market trends, we provide ongoing technical support and equipment upgrades. Our R&D team continuously develops new technologies and products to meet growing client demands. We also offer equipment modification and performance upgrade services to help clients optimize and enhance their production lines.