In today’s industry and construction, the rolling door forming machine has assumed an increasingly important role as key equipment. It is not only the core equipment for producing high-quality rolling doors, but also an important support for building safety and improving the efficiency of industrial production. With the continuous advancement of science and technology, and with the vigorous development of the construction industry, the technology and performance of rolling door forming machines are also upgrading, making important contributions to the building and development of modern society.

What is a rolling door forming machine?

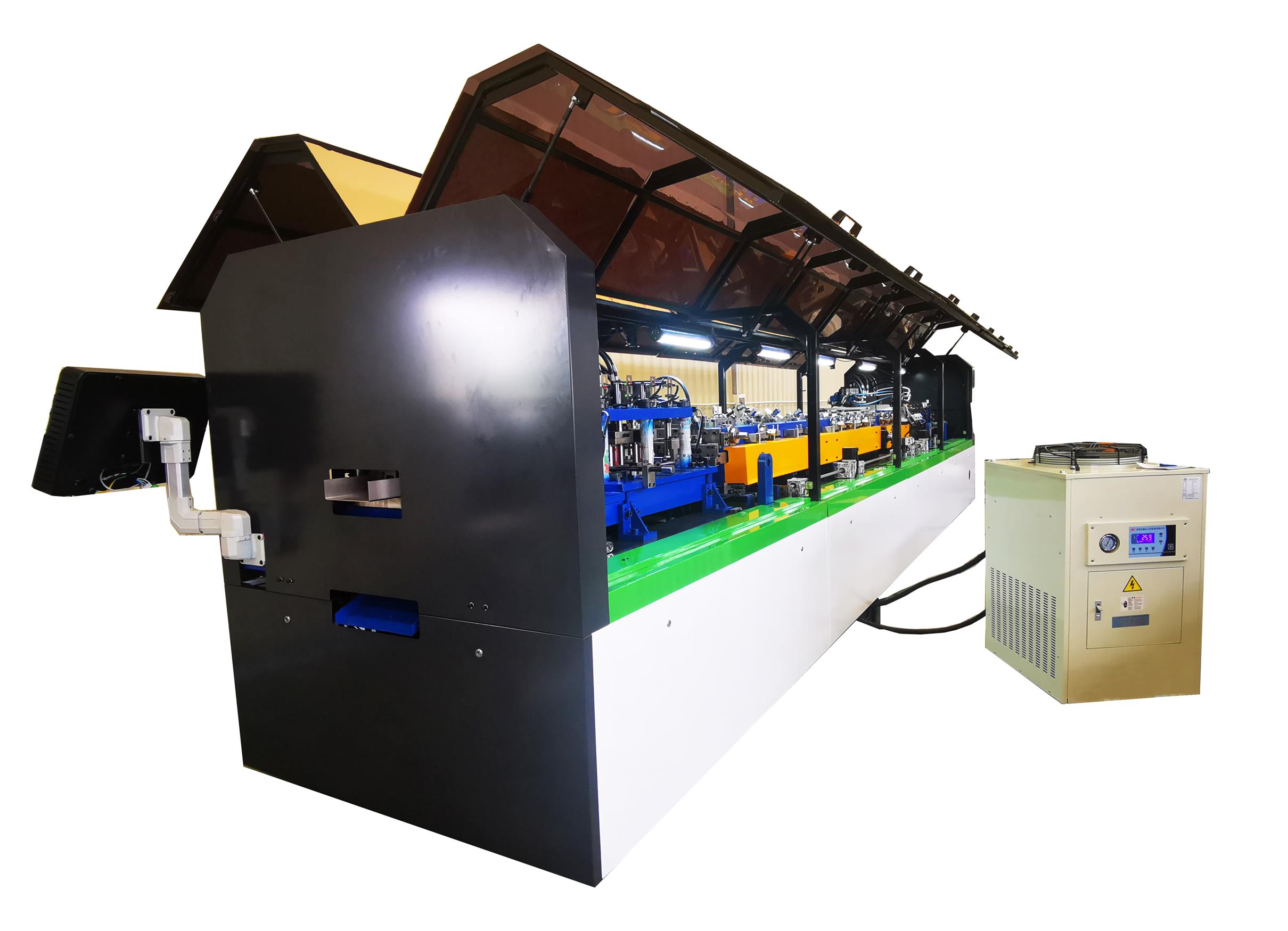

A rolling door forming machine is professional mechanical equipment specially assigned to process raw materials such as metal sheets into rolling doors. This equipment acts as the core in the rolling door production process; hence, it determines the quality, precision, and production efficiency of rolling doors.

From a structural point of view, the rolling door forming machine mainly comprises several key components such as the unloading system, the guide system, the forming host, the cutting device, and the control system. The unloading system is responsible for placing and conveying raw materials. Common unloading racks and hydraulic unloading machines are available, which can adapt to rolls of different specifications and weights. The guide system is like a precise “guide”, ensuring that the raw materials are accurately positioned and smoothly conveyed when entering the forming machine. This avoids offset or jamming and ensures accuracy in subsequent processing. The forming machine is considered to be at the “heart” of the whole equipment. It consists of a series of rollers carefully designed. The shapes, sizes, and arrangements of these rollers have been truly computed to enable gradual cold bending of the plate, and process the flat plate into a rolling door part with a certain cross-sectional shape according to the preset shape and size. The function of the cutting machine is to precisely cut the formed rolling door material as per the specified length to satisfy the requirements for rolling door length in different usage situations. The control system is like a “brain” of the apparatus, which ordinarily utilizes advanced PLC (programmable logic controller) technology through which an operator can easily set various production parameters such as forming speed, cutting length, etc., for automated production that greatly increases both production efficiency and stability of product quality.

The rolling door forming machine operates on the principle of cold-bending forming technology on metal sheets. It is a fully mechanical process with very crisp and clear logic governing the procedures. While operating, the unwinding unit initially very gradually unrolls the metal strip and passes it on one edge of the strip to the guiding unit. This guiding unit carries out initial positional adjustment and steering of the strip to make certain that the strip can enter the forming mainframe correctly.

As the sheet goes into the forming host, a set of rollers mounted on the main shaft starts to operate. These rollers face each other, and the shape and spacing of every pair of rollers are carefully adjusted according to design requirements for the rolling door. As the sheet passes between them, they apply continuous and uniform pressure to it, forcing it gradually to undergo plastic deformation. This is comparable to a skilled craftsman patiently shaping various forms out of soft dough. The sheet will be gradually bent and folded along a preset path and method until it finally forms a rolling door blade or some other component having a specific cross-sectional shape.

After the sheet has been formed, it passes into the cutting apparatus. This apparatus will take accurate cuts of the continuously formed sheet material according to preset length parameters with the aid of a high-speed cutting tool, for example, a saw blade or just a blade. To ensure that the cut is done accurately and in quality, normally this apparatus is fitted with some high-precision positioning and control systems to make sure that the length of every piece of rolling door material is uniform.

The control system is always at the center of the whole working process. The operator just inputs the desired production parameters through the control panel, such as sheet thickness, forming speed, cutting length, etc., and the control system coordinates the work of each component to realize efficient and accurate automated production. Such an automated way of production not only greatly heightens the efficiency of production but also greatly decreases human factors’ impacts on product quality; hence, every rolling door meets quality standards strictly.

Used a lot in today’s industries

- Warehouse in a factory

In the warehouses of the factory, rolling doors from rolling door forming machines play an essential role. They provide an efficient management method for storage as well as entry and exit of goods. For instance, take a huge electronic equipment manufacturing plant; its warehouse keeps large amounts of electronic components and finished products. The frequency of goods entering and leaving is very high daily. The rolling door has greatly improved the efficiency of cargo loading and unloading because it opens fast. Whenever the truck arrives at the warehouse location, just a simple press on a remote control shall make the rolling door rise virtually instantly so that the truck can drive into the warehouse for loading and unloading operations. After loading and unloading, then again, this rolling door shall come down quickly, thus minimizing contact time between the warehousing space and the outside environment. It lowers the chance of dust, bugs, and other things getting into the storage place. It keeps the area clean where stuff is kept. Also, it helps with keeping heat in and stopping moisture to a certain level. For some electronic parts that need a clean place to work well, this is very important. At the same time, the strong build of the door that rolls also gives a promise for having safe safekeeping of warehouse items. This stops problems like stealing from happening. - Logistics Center

The logistics center is very important as it is a main place of goods transportation and flow. Therefore, it demands fast loading and unloading of goods at a high pace. Here, the rolling door, which is produced by the rolling door forming machine, fully exploits its advantages. Normally, in each loading and unloading area of the logistics center, multiple rolling doors can be controlled in different zones according to various needs concerning the transportation of goods. When opening such a rolling shutter door, for example, forklifts, trucks, and other means of transport will enter and leave unimpededly, hence there is much better efficiency in terms of turnover of goods. Apart from that, this rolling shutter door has quite good sealing properties,s whereby internal temperature and humidity levels are kept from external factors. This is very important for some goods that need to be stored at constant temperature and humidity, for example, food and medicine. At night or during non-working hours, the logistics center becomes a safe line of defense with the closed rolling shutter door to ensure the safety of goods and equipment. - Other factory scenes

Rolling shutter doors have an equally important role in industrial scenes, such as workshops and production lines. Inside the workshop, rolling shutter doors may be applied to separate different work areas; this enables flexible separation of production areas. When equipment maintenance, product debugging, or special production operations are performed in one area, it can be isolated by closing the rolling shutter door from other areas; this ensures both the independence and safety of the work and also does not hinder the normal production order of the entire workshop. The rolling shutter door is a material transport control in the production line. As soon as the material gets to a certain spot, the rolling door opens by itself, and the material goes without any problems; after the material has passed, the rolling door shuts right away so that no dirt can get into the production line and make sure that work can continue without any problems. Its quick response features suit well how efficiently the production line should operate, giving strong help for making production even more efficient.

Importance of Building Safety

- Physical Safeguards

The rolling door is good in physical protection and creates a solid line of defense for building safety. Because of its sturdy and strong characteristics, it can resist the invasion of all kinds of external forces. This includes daily accidental collisions, and even if there is malicious destruction by criminals, the rolling door will ensure the safety of the interior space of the building with its strength. Commercial stores are telling examples; when no one is on duty during the night, the rolling door will be tightly closed. With thick door panels and locks that are sturdy locks, it is not easy for thieves to break through; hence, it reduces the probability of theft that could happen and also protects goods and property in the store. - Fire-resistant and flame-retardant

The fire shutter doors are the primary components of the building safety system during a fire. When a fire breaks out, it is this door that closes quickly to isolate the fire to one particular area, thereby preventing the spread of the blaze and creating an opportunity for people to be evacuated safely and for the fire to be brought under control. Such special functions come from special materials used in making fire shutter doors and their structural designs. Normal high-temperature steel and inorganic fiber composite materials make up most fire shutter doors because these maintain integrity under the structure during a fire. Internally, the standard inorganic fillings are rock wool or glass wool as heat insulators and flame-retardants to increase performance levels against fires; they help block high temperatures and flames from spreading easily. - Emergency evacuation assistance

In case of an emergency, such as fire or earthquake, the shutter door can integrate with the building’s evacuation system to provide solid support in quickly evacuating the personnel. Certain shutter doors are specifically designed for emergency evacuation and come with special functions and devices.

Key points for choosing a high-quality rolling door forming machine

Performance parameters

The performance parameters of the rolling door forming machine are directly related to the quality and production efficiency of the rolling door. Therefore, it is an important consideration in selecting a rolling door forming machine.

- Power is the main parameter that determines the power of the forming machine. A forming machine with higher power can easily cope with high-intensity production tasks and operate stably when thicker metal sheets are processed so that those sheets can form smoothly. Taking the common electric rolling door forming machine small manufacturers may choose equipment in 5-10 kilowatts to produce civilian rolling doors of ordinary thickness, while large industrial production enterprises have to mass-produce industrial rolling doors with high strength and thick plates; hence it requires a forming machine with power more than 20 kilowatts for efficient and stable production. If the power is not enough, the forming machine may have issues like getting stuck and moving at an unsteady speed while working, which not only affects how well things get done, but can also cause a drop in product quality, like improper forming shapes of rolling doors and major size differences.

- Processing speed is another important factor that affects production efficiency. The faster the processing speed more rolling doors can be produced in a unit time and hence increase the company`s production capacity. Different types of rolling door forming machines have different processing speeds. Ordinary mechanical transmission forming machines may have a processing speed of about 5-10 meters per minute; Advanced servo drive technology forming machines may have a processing speed of 15-20 meters per minute or even higher. In such huge order volume scenarios, like manufacturers supplying rolling doors to large shopping malls, logistics parks, etc., selecting a forming machine with a fast processing speed will help to complete orders within the specified time and hence meet customer needs, improving market competitiveness for the company. However, the processing speed is not supposed to be the faster, the better. Too fast a speed may affect forming accuracy, so it is necessary to find a balance between speed and accuracy.

- Accuracy is the major indicator for assessing the quality of rolling door forming machines. High-precision forming machines ensure that the rolling doors are accurate in size and regular in shape, and the smoothness and stability of the rolling doors during installation and use. The accuracy of the forming machine depends mainly on how its manufacturing process and control system have advanced.

Brand and reputation

Among the many rolling door forming machine products, picking products from famous brands and makers with a good name is an important plan to cut procurement risks and ensure equipment quality.

Better brands often mean better quality and more reliable performance. These companies have come out on top in long-term market competitions by amassing experience and technical prowess; they have advanced production equipment and strict quality control systems. For example, internationally known brands, Germany’s Horman and Italy’s Ferretti — these two companies have long histories and excellent reputations in rolling door forming machines; their products are mainly high-quality, high-performance, and intelligent. R&D oriented to the technology plus innovation these continuously provide technically advanced products with excellent performance to satisfy the market plus at the same time keep a tight check on all aspects of their manufacturing processes-from raw material selection through parts/component processing ap to assembly/commissioning of complete machines whereby strict quality standards are followed to ensure product quality & reliability.

A good reputation is the recognition and trust of consumers in brands and products. By understanding the user experience and evaluation of other users, you can have a more intuitive understanding of the actual performance, stability, after-sales service, and other aspects of the product. When choosing a rolling door forming machine, you can obtain word-of-mouth information about different brands and manufacturers through Internet searches, industry forums, and consulting peers. If a brand’s products have a good reputation in the market, it means that they perform well in actual use, can meet the needs of users, and have also been recognized by users in terms of after-sales service. On the contrary, if a brand has a large number of negative reviews, such as frequent product quality problems and inadequate after-sales service, then you need to consider it carefully when choosing.

Brand and reputation can be judged in many ways. You first check the brand’s past and present market share. A brand that has a long past with an increasing present market share usually has better strength and a good reputation. Secondly, awards and honorary certificates of the brand are important proofs of brand strength and product quality. You can also check the influence of the brand on the industry, such as whether it participates in standard setting for the industry or has patented technology. At the same time, other users’ evaluations and recommendations are also very important to refer to. Real user feedback can provide a strong reference for our selection.

After-sales service

The long-term and stable operation of the rolling door forming machine is inseparably linked to perfect after-sales service, which mainly includes equipment repair, maintenance, and technical support.

- Maintenance service is a Key Link in After-Sales Service. In the long-term use of the rolling door forming machine, various faults are InevitAble. Wear of mechanical parts and electrical system failure— timely and efficient maintenance services can quickly solve these problems, reduce equipment downtime, and reduce production losses. A good manufacturer will have a professional maintenance team that has rich experience in maintaining and possesses professional technical knowledge to quickly and accurately diagnose the cause of the fault to take effective maintenance measures. At the same time, this manufacturer will also reserve sufficient spare parts to ensure that damaged parts can be replaced in time during maintenance to improve efficiency.

- Maintenance service has vital roles in extending the service life of the forming machine and stabilizing equipment performance. With regular maintenance, potential problems can be detected timely manner and dealt with in advance to avoid failure occurrences. Generally, maintenance includes cleaning, lubrication, inspection, and adjustment of parts. Manufacturers will develop detailed plans for maintenance according to the use and characteristics of the equipment and distribute this information to users through guidance and training on maintenance. For example, during regular working hours, the rollers of the molding machine need to be lubricated to reduce wear; line connections of the electrical system are checked for any looseness to ensure safety. The molding machine will remain in excellent working order with regular maintenance, hence high production efficiency with a low equipment failure rate.

- Technical support is one of the important parts of after-sales service. During the use of the equipment, users may face technical problems and questions on how to operate the equipment or adjust parameter settings. Professional answers and guidance from the manufacturer’s technical support team will help users learn to better use the equipment. Some manufacturers will also provide operational training and technical lectures so that users can have professional knowledge about operational skills and maintenance of the equipment. Meanwhile, with technological development continuously growing, manufacturers further furnish users with equipment upgrade services, making it feasible for the equipment to adapt to new production requirements and technical standards.

The importance of the rolling door forming machine is self-evident

As a main machine in the area of modern industry and building safety, the importance of rolling door mold machines is clear. In industrial production, it gives fast and easy ways for the control and movement of goods in factory storerooms, logistic centers, and other places, greatly improving production efficiency as well as the speed of logistics turnover. In terms of building safety, the rolling door has constructed a strong protection line for the security of human lives and properties with its excellent physical protection capacity, anti-fire and emergency evacuation support functionality, and has become a necessary part of the building safety assurance system.

In selecting a rolling door forming machine, we should take into account the performance parameters, brand, and after-sales service. Performance parameters determine production capacity and quality; brand reputation reflects the reliability and stability of the product; and perfect after-sales service will provide long-term support for the stable operation of the equipment. Only high-quality rolling door forming machines can produce high-quality rolling doors that can satisfy modern industry and construction’s strict requirements for safety and efficiency.

With the continuous advancement of science and technology and the continuous development of society, I believe that the rolling door forming machine will continue to innovate and upgrade, play a more important role in the future industrial production and building safety, and create a safer, more convenient and efficient production and living environment for us.