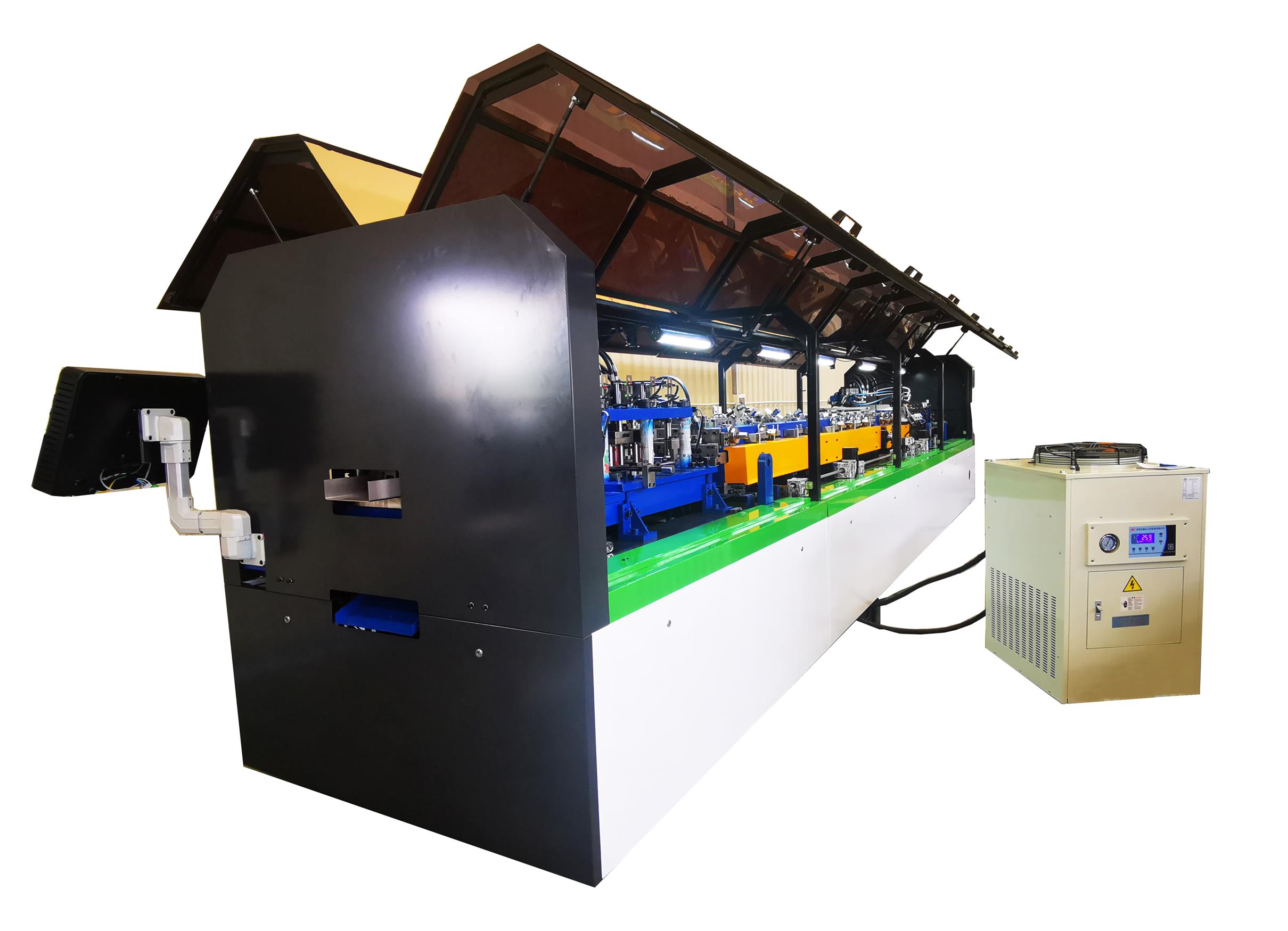

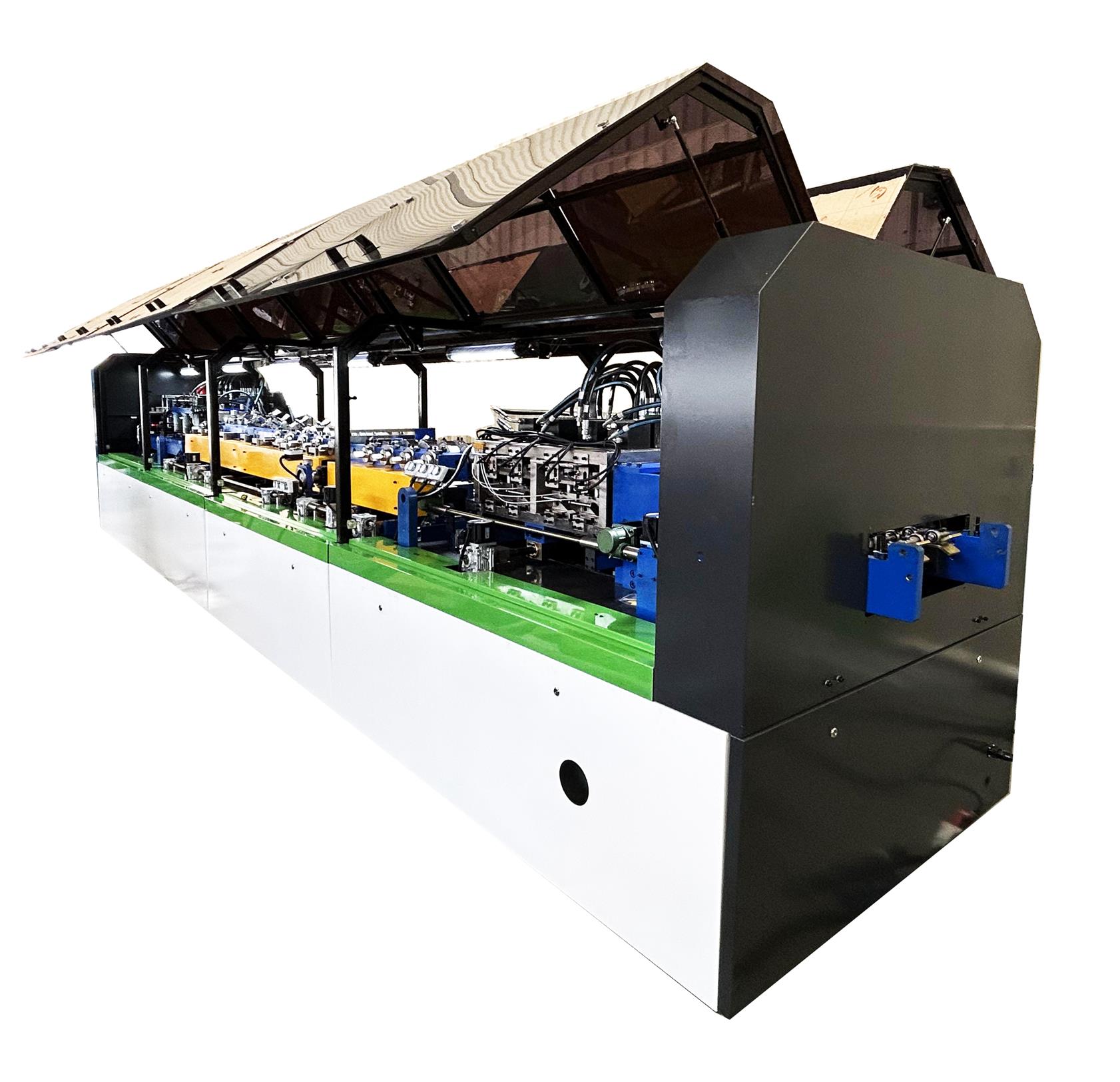

The automated rolling shutter door manufacturing system represents a new generation of industrial solutions specifically designed for the precision manufacturing of rolling shutter components, marking another peak in intelligent manufacturing. This smart roll-forming equipment integrates cutting-edge automation technology, enabling end-to-end unmanned production from precise material feeding to automated packaging of finished products, significantly enhancing operational efficiency in industrial applications and bringing unprecedented productivity and competitiveness to enterprises.

The system is equipped with an extremely intuitive and user-friendly human-machine interface (HMI) that greatly simplifies workflow management, allowing operators to quickly familiarize themselves with system operations without the need for extensive training. This design reduces labor costs and enhances work efficiency. Furthermore, its integrated digital control center utilizes high-precision sensing technology and advanced algorithms to maintain micron-level accuracy in terms of dimensional precision and contour consistency, ensuring strict compliance with international quality standards. This guarantees structural integrity and functional reliability of each product, providing users with safer and more reliable rolling shutter components.

In summary, this automated rolling shutter door manufacturing system stands out in the modern industrial manufacturing sector with its exceptional performance, high level of automation, and intelligent management approach, setting a new benchmark for the precision manufacturing of rolling shutter components.

Running Video Link

How Shuttter Door Roll Forming Machine Work

The roller shutter forming machine stands as a cornerstone equipment in modern architectural material manufacturing, employing advanced roll forming technology to transform flat metal coils into precisely engineered curtain door profiles. Through a sophisticated series of progressively arranged forming rollers, this automated production system continuously processes raw materials – typically galvanized steel, aluminum alloys, or color-coated sheets – into interlocking slat components with millimeter-level dimensional accuracy.

At the heart of its operation lies a computer-controlled forming process that enables:

1) High-precision profile shaping (tolerance control within ±1mm)

2) Variable cross-section designs through modular roller tooling

3) Integrated punching and embossing stations for functional features

4) Speed synchronization up to 18m/min with mechanisms

Профили машины для изготовления жалюзийных ворот

Advantages of The Shutter Door Roll Forming Machine

A significant advantage of the roller shutter door roll forming machine lies in its exceptional precision and efficiency. This versatile machine is adept at processing a wide range of materials and specifications, rendering it suitable for diverse sectors, encompassing construction, industrial, and commercial applications.

By utilizing this machine, manufacturers experience a substantial reduction in labor needs, coupled with a notable increase in production speed and consistency of the shutter door slats. Furthermore, the machine guarantees uniformity and stability across all produced components, thereby ensuring the superiority of the final products.

Owing to its efficiency, operational stability, and adaptability, the shutter door roll forming machine serves as an indispensable resource in contemporary shutter door manufacturing. It assists businesses in fulfilling the escalating and varied demands of the market with ease.

Компоненты машины для изготовления жалюзийных ворот

Детали машин

1) Кормление

The positioning feeding system is a key part to ensure the accuracy and high efficiency of production. Its advantages are reflected in the optimization and management of material control throughout the entire process.

2) Rоллерс машины для изготовления жалюзийных дверей

Ролики изготовлены из высококачественной подшипниковой стали GCr15, точеные с ЧПУ, термически обработанные, с твердым хромовым покрытием.

3) Формирование фреза

4)Система управления PLC (2 типа на выбор)

Простота в эксплуатации

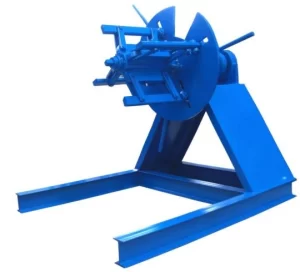

Машина для изготовления жалюзийных дверейDэкойлер (2 типа на выбор)

- Ручной разматыватель 2. Гидравлический разматыватель