The metal roofing industry has experienced a significant change in the past decade. Customers are more aware of the need for better buildings, and contractors are required to provide aesthetically pleasing, durable roofs that require little to no maintenance, regardless of the job site’s complexity or weather. In the middle of all of these expectations, the maskin för stående sömmar has quietly become one of the most important pieces of equipment for a roofing company. It defines the speed at which you can create panels, the accuracy of each seam, the efficiency of your team, and ultimately the degree to which you can expand your responsibilities.

However, despite its significance, many roofing companies have difficulty choosing the appropriate machine. Some people shop purely based on the price, while others focus solely on speed. Some people follow the competitors’ choices without understanding their own process, and others underestimate the importance of small details like the alignment of the roller, the stability of the frame, or the design of the cutter. What should be a strategic decision becomes a risk.

What Your Business Really Needs

Before looking at any machines, before assessing the speed of forming, and before requesting quotes, it’s first necessary to consider your own business model. Every company that operates on roofs has different scales of operation, different materials, different job sites, and different market expectations. If you bypass this step, you may purchase a machine that is effective in theory, but it will fail in your real environment.

Start by studying the typical pattern of your employment. For example, a local contractor that has a consistent volume of residential projects doesn’t need the same machine as a company that produces panels for retailers. Residential contractors often have to deal with smaller panels, frequent changes in profile, and confined spaces, which makes a compact and simple-to-alter machine more attractive than a fast industrial line. On the other hand, a facility that produces panels for multiple installation teams must have uninterrupted output, high production rates, and consistent dimensional consistency across long lengths of panel.

The type of material is equally significant. Some areas have a preference for galvanized steel, while others utilize aluminum or copper. High-end projects may utilize zinc or polystone. Every material has a different behavior during the process of forming, and choosing a machine that is not designed for your primary material can lead to surface markings, uneven ribs, or problems with the seam. You must also consider the style of your roof and whether it demands narrow or wide panels, high or low ribs, and mechanical or Snap-Lock seams. These aren’t small matters— your daily procedure is dependent on them.

If the majority of your projects involve forming panels in place, mobility is essential to complete them. Having the ability to move the machine easily, set it quickly, and produce panels at the exact location they will be installed can reduce the time needed for transportation and prevent damage to the panels. Conversely, if you operated in a space-equipped facility with equipment that handles coil, a larger, heavier machine would have a higher degree of accuracy and longevity.

Ultimately, the first step in selecting the right standing seam machine is not about studying the specifications of the machine, but rather understanding your own personal roofing philosophy- what you create, where you operate, and how your team interacts.

Key Technical Considerations That Actually Matter

Once you understand what you need from the machine, you can assess its technical merits. Not every attribute listed by brokers is significant, and many novices are floundering because of the impressive-sounding attributes. The actual performance of a stationary seam machine is influenced by the mechanical precision of the machine, the compatibility of the material, and the long-term stability of the machine—not its marketing pitch.

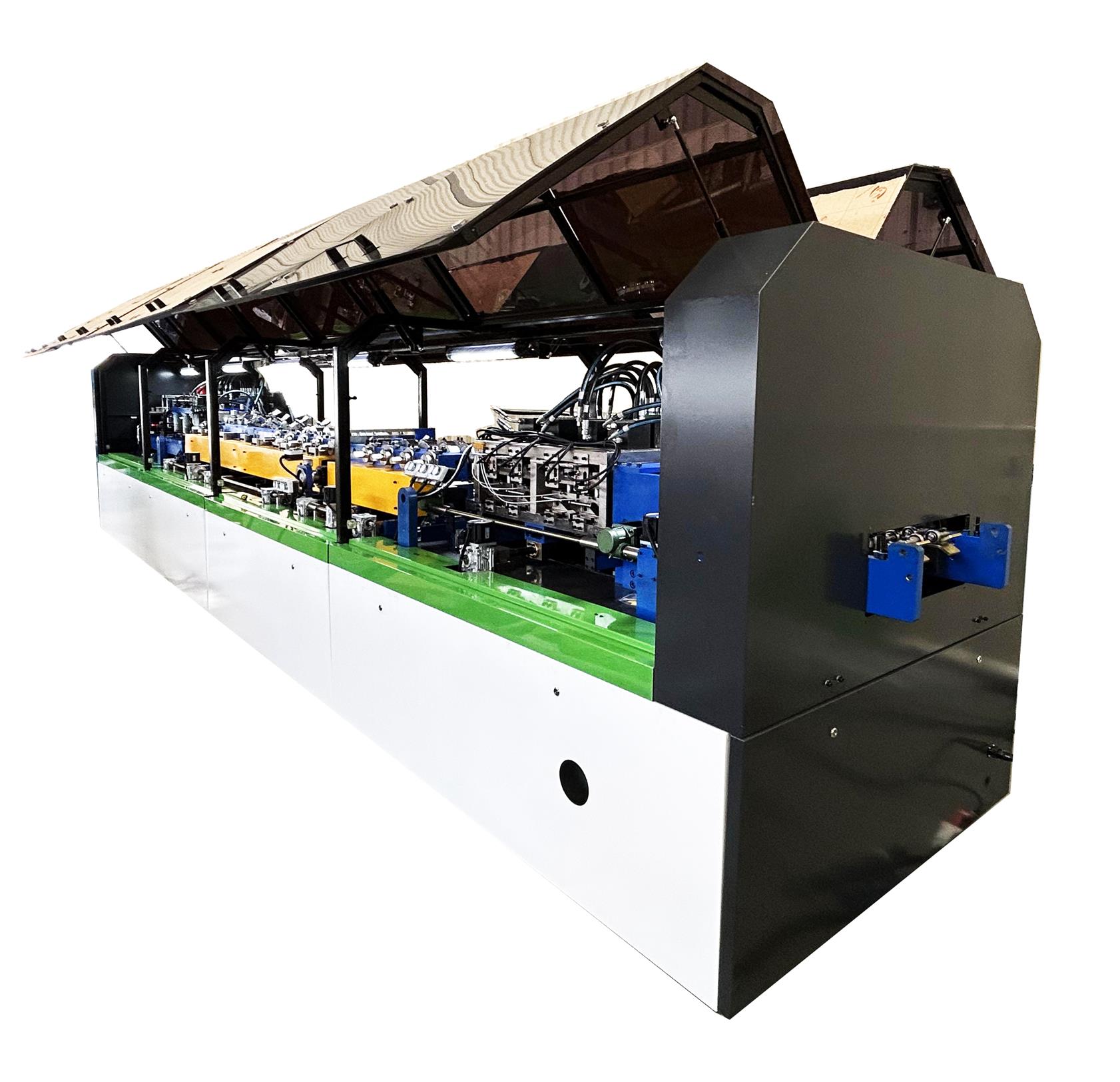

The center of any stationary sewing machine is composed of its rollers. Their composition, hardness, consistency, and alignment have a direct impact on the quality of the roofing panels. Even small temperature changes can lead to the formation of oil, the wavy ribbons, or misaligned seams. When reviewing machines, it’s important to consider the degree to which the rollers are compacted, the consistency of their size, and the alignment of their stations. A machine with 10 effective roller stations that are designed appropriately will have a performance superior to a machine with 15 stations that are poorly designed.

Another important technical aspect is the machine’s capacity to deal with your material thicknesses. Many machines have a claimed compatibility that is wider than the average, but in practice, some have difficulty with thicker steel or softer aluminum. If the machine’s roller pressure is not properly designed, materials that are softer than necessary may show signs of imprinting or micro-deformations, while harder materials may lead to long-term wear or tension in the frame. The substance you most frequently utilize is the one the machine must master with absolute precision.

The cutter system has a significant impact on the installation process. A sharp, clean cut that lacks burrs ensures that the panels are consistently aligned and avoids the time-consuming process of trimming or correcting the edges on site. raulic cutters provide power and consistency, while flying cutters are ideal for high-speed production lines. The primary consideration is not just the mechanism for cutting, but also how it interacts with the forming process to produce consistent, repeatable cuts.

Control systems are another means of evaluation, but they should be considered in the context of practicality. Advanced automation is beneficial in factories that require large amounts of repetitive production. However, for mobile contractors, the overly complex controls may lead to unnecessary complications. The proper ratio is based on the frequency of your needs to switch lengths, profiles, or material thicknesses.

A Quick Reference List: The 10 Factors You Should Never Ignore

Although this article avoids excessive bullet points, certain factors are simply easier to absorb as a concise list. These are the ten non-negotiable elements you should evaluate in any standing seam machine:

Roller accuracy and material hardness

Frame rigidity and structural stability

Material thickness compatibility

Panel profile precision and repeatability

Clean, reliable cutter system

Ease of adjustments and profile switching

Forming speed appropriate to your workflow

Mobility or fixed-line suitability

Spare parts availability and maintenance convenience

After-sales support and technical guidance

Every machine you inspect should be evaluated on these points. If a supplier avoids answering any of these questions clearly, take that as a warning.

Durability and Long-Term Value

Selecting a stationary sewing machine is not simply a comparison of attributes; it’s also a matter of understanding the long-term cost. A machine that is initially more expensive may become more economical in the long run when considered in conjunction with the aforementioned qualities, including roller life, consistency, and the frequency of necessary revisions.

The most efficient machines utilize steel frames that are thicker than normal and do not show any sign of warp or flex over the long term. They contain high-end bearings, which are well-balanced, and have a hardened roller that maintains the profile of over 100,000 meters of production. Machines with less powerful structural design may initially seem adequate, but over time, even small deformations in the frame can lead to misalignment across the roller stations and lead to inconsistency in the panel.

Maintenance is another significant expense factor. Machines that are frequently re-set up or have a rapid wear rate decrease your productivity and increase your costs of operation. Before purchasing a part, ask the seller if the parts are standardized, if the documentation is clear, and if routine maintenance is possible without special tools. A proper machine design allows users to substitute bearings, alter stations, or clean rollers without taking extensive time.

You should also consider the supplier’s propensity towards after-sales service. Even the most effective machine may require occasional recalibration, partial replacement, or technical assistance. A supplier that responds to problems quickly, provides troubleshooting assistance, and has parts to replace is more valuable than a supplier that simply sells a machine and then vanishes.

The Strategic Impact of Choosing the Right Machine

The correct choice of a standing seam machine is not simply a tool for production; it also shapes the way you conduct business with your roofing. It facilitates the acceptance of new jobs, the creation of panels on a more restricted schedule, reduced labor costs, and minimized waste material. For contractors that previously acquired panels from external vendors, possessing a machine will lead to increased control over the delivery of panels, their accuracy, and the project’s margins. For manufacturers who produce goods in factories, a more powerful machine may lead to an opportunity to serve larger customers or to expand into a more architectural-grade form of roofing.

Contractors often don’t take into account the psychological benefit as well. When installers consistently receive panels that are perpendicular, flat, and accurately cut, their installation rate increases. They have less trouble maintaining the roof’s position, the seams are consistently sealed, and long panels are positioned without having to be corrected. This not only promotes productivity but also increases faith in the team as a whole.

Additionally, providing high-quality standing panels that are seamless helps to promote your brand. Architects, builders, and clients appreciate clean joints, direct shadows, and uniform stripes. A machine that consistently increases the visual appeal of your installations. Eventually, this can result in more significant projects and a repeat customer.

A Practical Comparison List for Decision-Making

When you are ready to compare machines, use the following simplified comparison list. It helps you judge machines fairly without being distracted by non-essential features:

Does the machine produce perfectly aligned seams with no twisting?

Are the rollers hardened and precision-ground?

Does the cutter leave a clean, installation-ready edge?

How stable is the machine during long panel runs?

Is the control system suited to your working environment?

Can the machine handle the materials you use most?

Are adjustments quick and intuitive?

How approachable is the supplier when you need support?

This list represents the practical realities of owning a standing seam machine, not theoretical specifications.

Avoiding the Most Common Buyer Mistakes

Many contractors who are upset with their purchases will typically fall into the same pitfalls. One common error is purchasing a machine that seems less expensive, but which, in the long run, will cost more due to repairs, downtime, and poor quality of the panel. Another common error is selecting a machine based on its maximum speed without taking into account the potential conflicts that arise from the job site’s flow. Fast-ripening panels are of little value if workers cannot quickly pick them up, carry them to a nearby job site, or install them.

Some consumers only consider the looks of sample boards. While the quality of the sample is important, it’s equally important to know if the quality is consistent over long production runs. A machine may have a perfect 2-meter sample, but it may have problems with a 15-meter panel due to the misalignment of the roller or the insufficiency of the frame.

A third error is not to consider the future. Roofing companies increase in size, projects evolve, and material trends alter. Selecting a machine that only supports one profile or a limited range of thicknesses may impede your growth later on.

A Final Checklist for Confident Purchasing

Before making your final choice, ask yourself these three essential questions:

Will this machine support the type of projects I expect to handle in the next five years, not just today?

Can this machine maintain perfect panel consistency during long production runs and daily jobsite use?

Do I trust the supplier to support me if I face issues after the purchase?

If your answer to all three is yes, then you have likely found the machine that truly fits your business.

Choosing a Machine That Builds Your Future

A long-term partner that has a significant impact on your project’s quality, your installation’s efficiency, and your reputation is more than just a piece of equipment. Selecting the appropriate one is dependent on understanding your business comprehensively, recognizing the technical aspects that directly affect performance, and avoiding overly specific details that don’t represent real-world usage.

The most efficient machine for your roofing business is the one that provides accuracy, consistency, material compatibility, and long-term durability. It’s the apparatus that your installers rely on, your production team enjoys, and your customers are indirectly commended for the clean lines of their finished roofs.

If you choose this option with care and strategy, your existing standing seam machine will become one of the most beneficial investments in your entire roofing career. This will also serve as a foundation for additional growth.