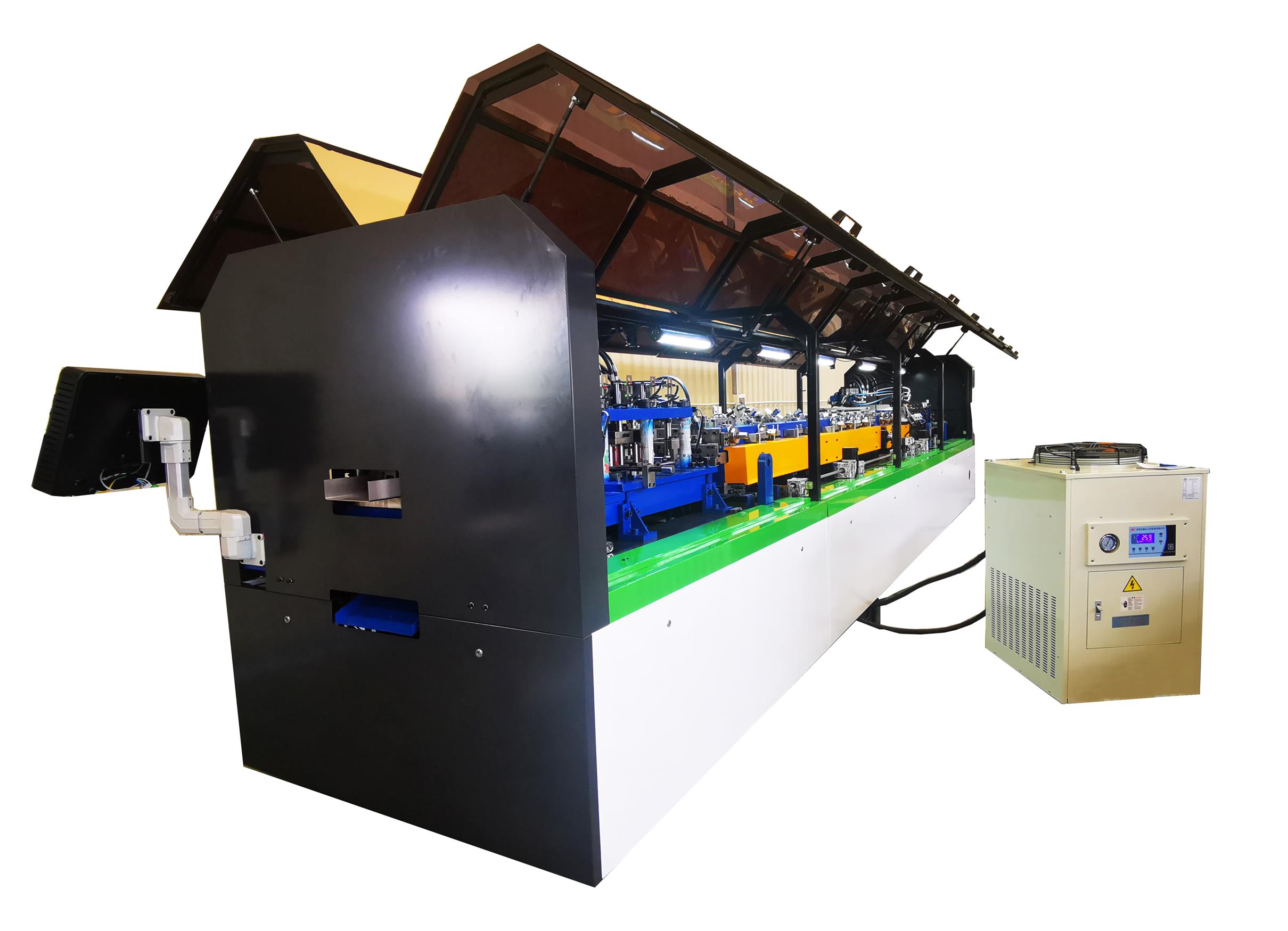

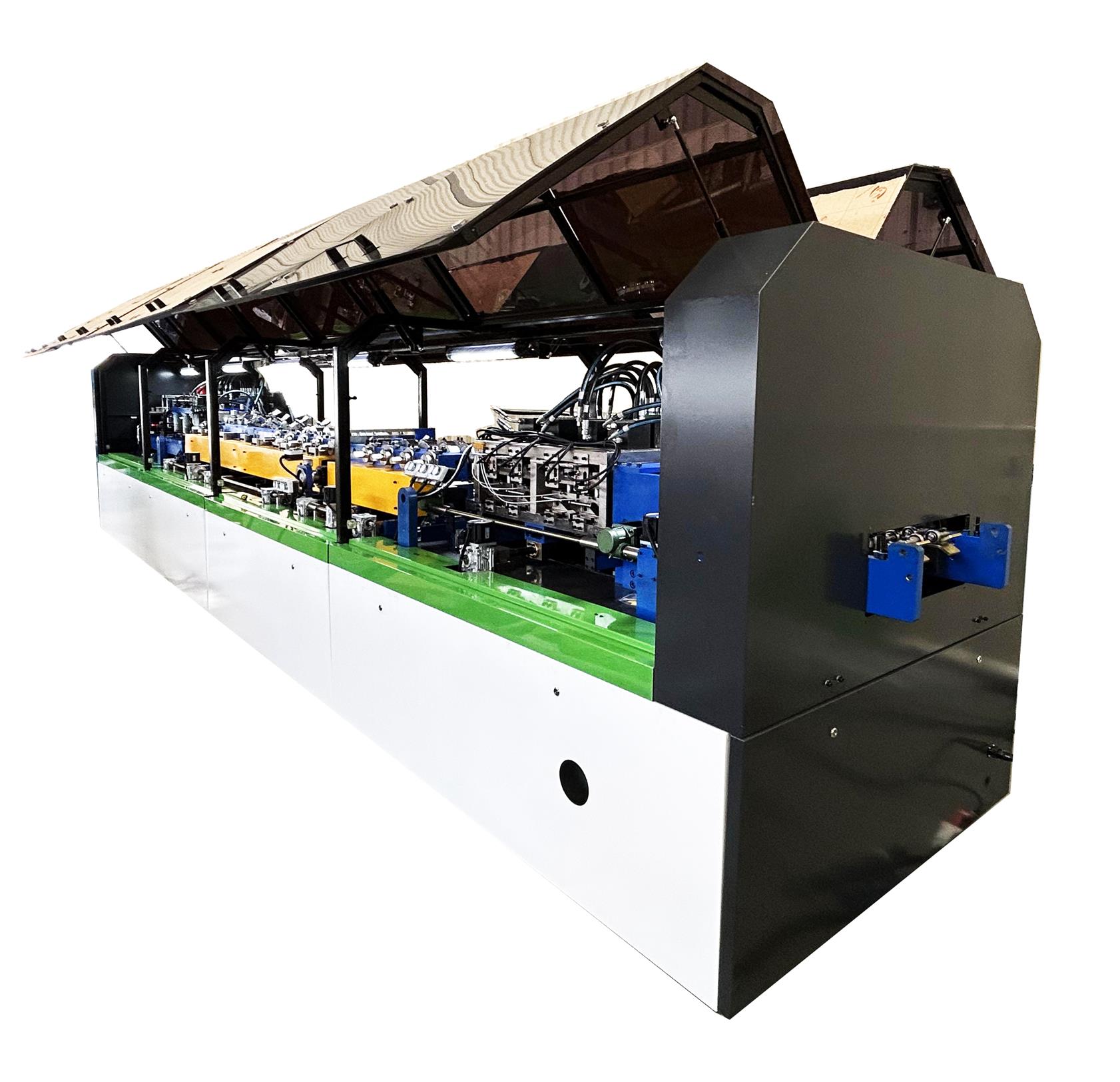

Metal Zemin Makinesi, yüksek kaliteli metal zemin plakalarının üretimi için tasarlanmış gelişmiş bir ekipmandır. Döşeme şekillendirme makinesi, döşeme plakalarının doğru şekillendirilmesini ve verimli üretimini sağlamak için bir çözücü ve tabanı, bir bobin kılavuz cihazı, bir rulo şekillendirme sistemi, bir kesme sonrası cihazı, bir hidrolik istasyon ve bir çıkış tablasından oluşur.

Our company has won wide acclaim in the field of metal floor production for its efficient, stable and precise performance. We look forward to establishing a long-term and stable cooperative relationship with you

Characteristics and application advantages of metal floor machine

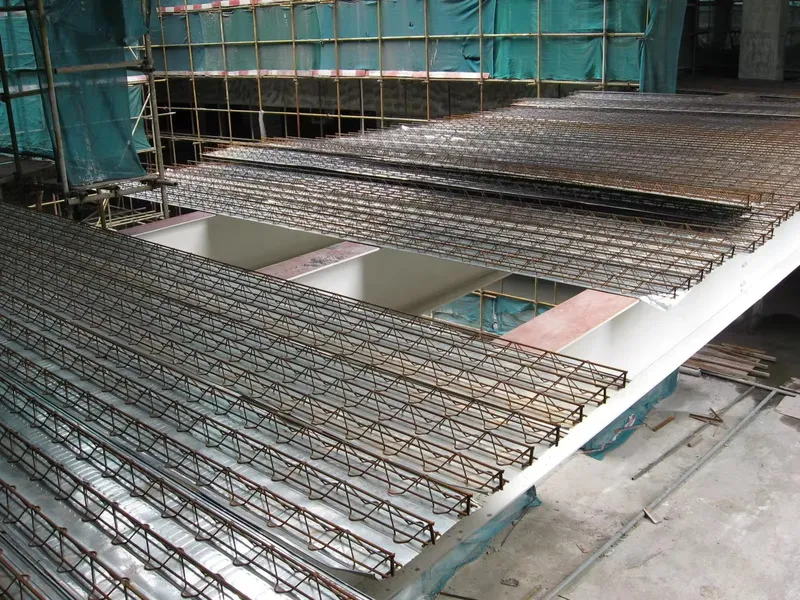

Because of its many benefits, metal flooring has steadily supplanted conventional flooring as a cutting-edge building element in the construction sector. The essential piece of machinery used to create this high-performance floor, the metal floor machine, also exhibits its own appeal.

1. Outstanding performance of the material

Because of its superior mechanical qualities and increased load capacity, metal floors stand out and greatly increase a building’s overall stability. Furthermore, the building’s exceptional resilience to fire, corrosion, and weather offers a strong assurance of its longevity and safety.

2. Easy to use and effective construction

The prefabrication technology used in the metal floor machine’s production allows for a quick and easy installation procedure. This not only significantly decreases the time needed for construction, but it also lessens the need for expert personnel, which lowers labor expenses. Furthermore, as a result of less welding and cutting done on-site, there are also less safety risks throughout the building process.

3. Notable economy of scale

Metal flooring may initially cost a little more to buy than standard flooring, but there are several long-term advantages that make it worthwhile. First, the project may be finished and put into use sooner, generating advantages ahead of schedule, since the construction time has been reduced. Second, a metal floor has comparatively minimal maintenance costs and prolongs the building’s service life due to its resilience. Using metal flooring may lower the total cost of construction when all these aspects are taken into account.

4. Sustainability and environmental preservation

Because metal flooring can be recycled and reused, it is a great option for handling construction debris. The production of building trash may be greatly decreased, as well as the detrimental effects on the environment, by recycling and reusing metal flooring. Simultaneously, this aligns with the principles of sustainable development and green building, so encouraging the construction sector to progress towards a more eco-friendly and sustainable path.

Makine Teknik Parametreleri

| Hayır. | Öğe | Parametre |

| 1 | Makine boyutu | 11000*2200*1600mm |

| 2 | Makine ağırlığı | 11000kg |

| 3 | Makine gücü | 18.5kw |

| 4 | Hidrolik motor | 3.7kw |

| 5 | Yuvarlanma hızı | 0-18m/min |

| 6 | Rulo istasyonları | 22 |

| 7 | Makara malzemesi | 45#Steel |

| 8 | Etkili genişlik | özelleştirilmiş |

| 9 | Besleme genişliği | 1219mm |

| 10 | Gerilim | 380V 50Hz 3PH/Özelleştirilmiş |

| 11 | Malzeme kalınlığı | 0.8-1.2mm/Customized |

| 12 | Kontrol Sistemi | Schneider/Delta/Özelleştirilmiş |

Zemin kaplama makinesi profilleri

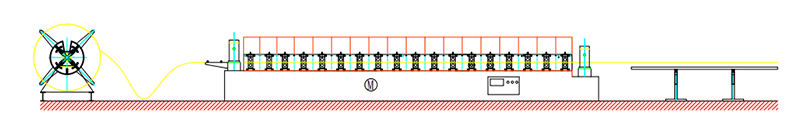

İş Akışı

Açıcı→Besleme Kılavuz Cihazı→Ön Kesim Cihazı(isteğe bağlı)→Rulo Şekillendirme Sistemi→Hidrolik Direk Kesme Cihazı→Çıkış Rafı

Components of the machine

- Besleme

- Hydraulic pre-cutter

- Rollers of floor decking machine

Silindirler yüksek kaliteli rulman çeliği GCr15'ten yapılmıştır, CNC tornalanmış, ısıl işlem görmüş ve sert krom kaplamalı olarak mevcuttur.

With feeding material guide, body frame manufactured of 300# H type steel by welding

- Floor decking machine forming cutter

Isıl işlem görmüş yüksek kaliteli kalıp çeliği Cr12'den yapılmıştır

- PLC Kontrol sistemi

Kullanımı kolay

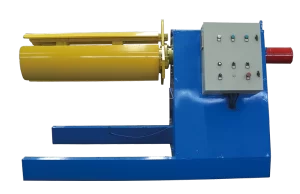

6.Decoiler

Manuel Açıcı: bir set

Güçsüz, çelik bobin iç delik büzülmesini manuel olarak kontrol edin ve durdurun

Maks. besleme genişliği: 1250mm, bobin ID aralığı 480mm±30mm

Capacity: Max. 5 Ton

With 5 tons hydraulic decoiler with car and without car for option

Hizmetlerimiz

Product Quality and Manufacturing

- Selection of Raw Materials: To guarantee the product’s strength and wear resistance, we use premium steel, such as Cr12 mold steel and GCr15 bearing steel, in the production of our metal floor slabs.

- Processing Technology: Heat treatment is utilized to enhance the material’s performance, and CNC lathes are used for precise processing. To further improve wear resistance, the roller surface is hard chrome coated.

- Strict Quality Control: To guarantee that every piece of equipment satisfies customer demands and national standards, strict quality control is implemented at every stage of the manufacturing process, from the acquisition of raw materials to assembly and commissioning.

Customized Service

Customization of Specifications: We provide a variety of models and specifications of metal floor slab roll forming machines to meet the demands of our customers.

Function Customization: We can modify certain equipment functions, including automated feeding and detection, in accordance with the production requirements of our clients.

After-sales Service

- Equipment Installation and Commissioning: To guarantee that the equipment is successfully integrated into production, provide equipment installation, commissioning, and trial operation services.

- Operation Training: To guarantee that operators are competent in the use and maintenance knowledge of the equipment, provide clients operation training.

- Repair and Maintenance: To guarantee the equipment’s long-term, steady performance, provide routine maintenance and maintenance services.

- Technical assistance: Assist clients with difficulties arising from usage by offering technical support and consulting services.