Spandrel makinesi terimi doğrudan belirli bir mekanik ekipmanı ifade etmeyebilir, ancak spandrel malzemelerinin üretimi, işlenmesi veya montajı ile ilgili ekipman veya süreçler için genel bir terimdir. Ev dekorasyonu alanında, spandreller (iç / dış tavan spandrelleri, koridor spandrelleri, kaburga spandrelleri ve düz spandreller dahil) benzersiz cazibeleri ve üstün performansları nedeniyle popülerdir.

Spandrel makinesi, spandrellerin işlenmesi, üretimi veya montajı ile ilgili çeşitli ekipman ve süreçleri kapsayan genel bir kavram olabilir. Ev dekorasyonu için tercih edilen bir malzeme olan spandreller, benzersiz cazibeleri ve üstün performanslarıyla piyasada geniş kabul görmüştür.

Spandrel Makinesinin Özellikleri

- Hem süsleyici hem de işlevsel: İç tasarımda bir öncü olan spandrel paneller, odanın estetiğini geliştirmekle kalmaz, aynı zamanda tavan ve duvarı sorunsuz bir şekilde birleştirerek çarpıcı bir görsel etki sağlar. Toksik olmayan ve küflenmeye karşı dayanıklı nitelikleri sayesinde ev atmosferi güvenli ve sağlıklıdır.

- Üstün kalite ve makul maliyetin ideal kombinasyonu: Üstün kalitelerine rağmen, spandrel paneller hala nispeten makuldür, bu da onları daha iyi bir yaşam isteyen tüm müşteriler için erişilebilir kılar.

- Zengin işçilik ve çeşitli malzemeler: Renkli çelik plakalar, alüminyum alaşımlar ve paslanmaz çelik gibi kaliteli malzemeler, rulo kaplama, laminasyon ve sofistike baskı gibi son teknoloji tekniklerle birlikte kullanılarak birçok stilin dekoratif gereksinimlerini karşılayan bir dizi renk ve stil üretilir.

- Orta kalınlık ve sağlam dayanıklılık: Spandrel levhanın düşük ağırlığı ve montaj kolaylığı korunurken, dayanıklılığı 0,55 mm, 0,6 mm veya 0,7 mm gibi çeşitli kalınlık seçenekleri ile garanti edilir.

Bir dizi ihtiyacı karşılamak için geniş çapta:

Ev içi dekor ve spandrel plakaları özellikle tavan yapımı için çok uygundur. Hafif, güçlü ve zarif nitelikleri oturma odası, yatak odası, fuaye, balkon ve diğer alanlara benzersiz bir parlaklık kazandırır. Olağanüstü esnekliği ve sınırsız yaratıcı potansiyeli, ticari alan dekorasyonu ve reklam dekoru gibi diğer sektörlerde de popüler olmasını sağlar.

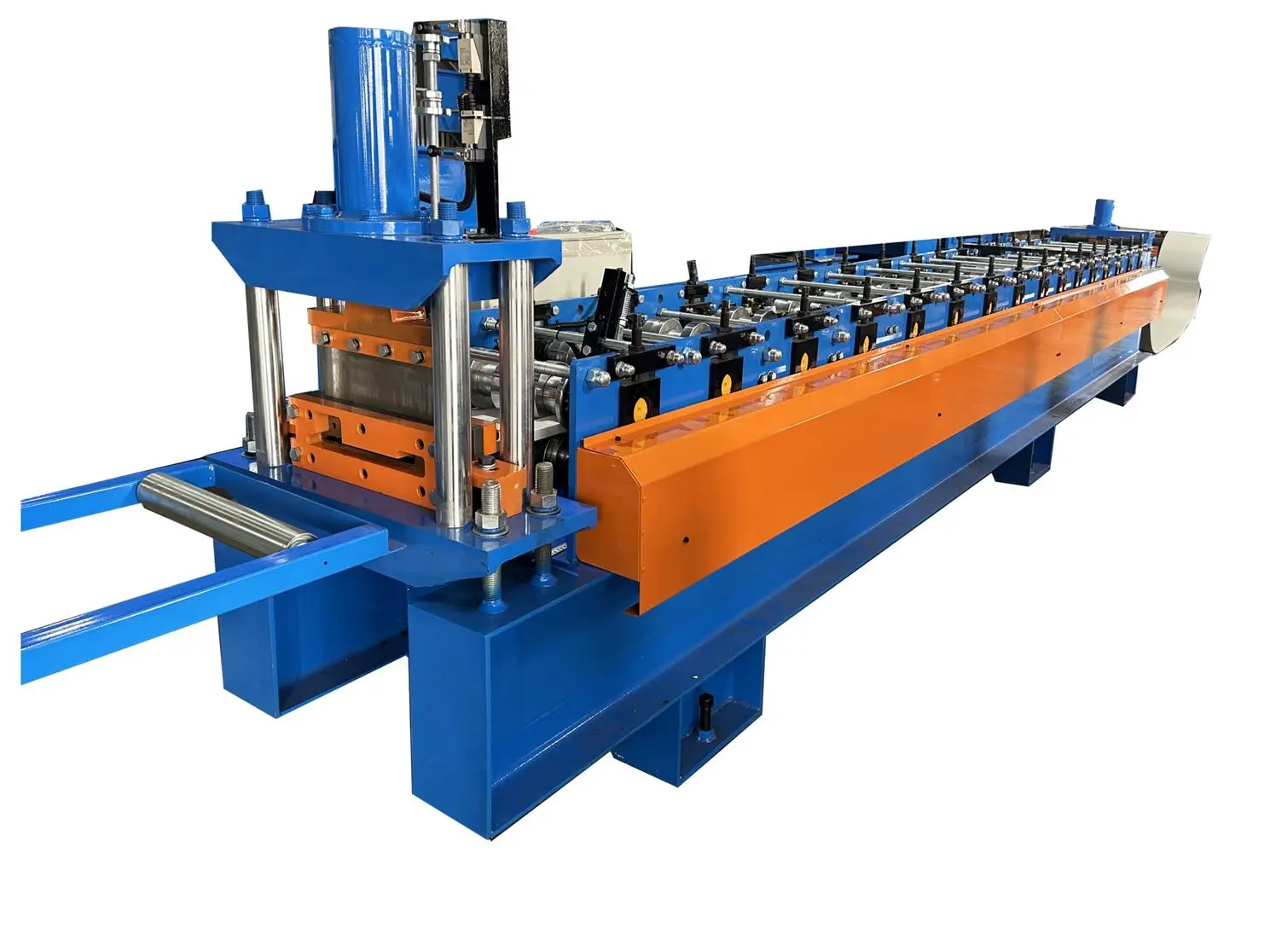

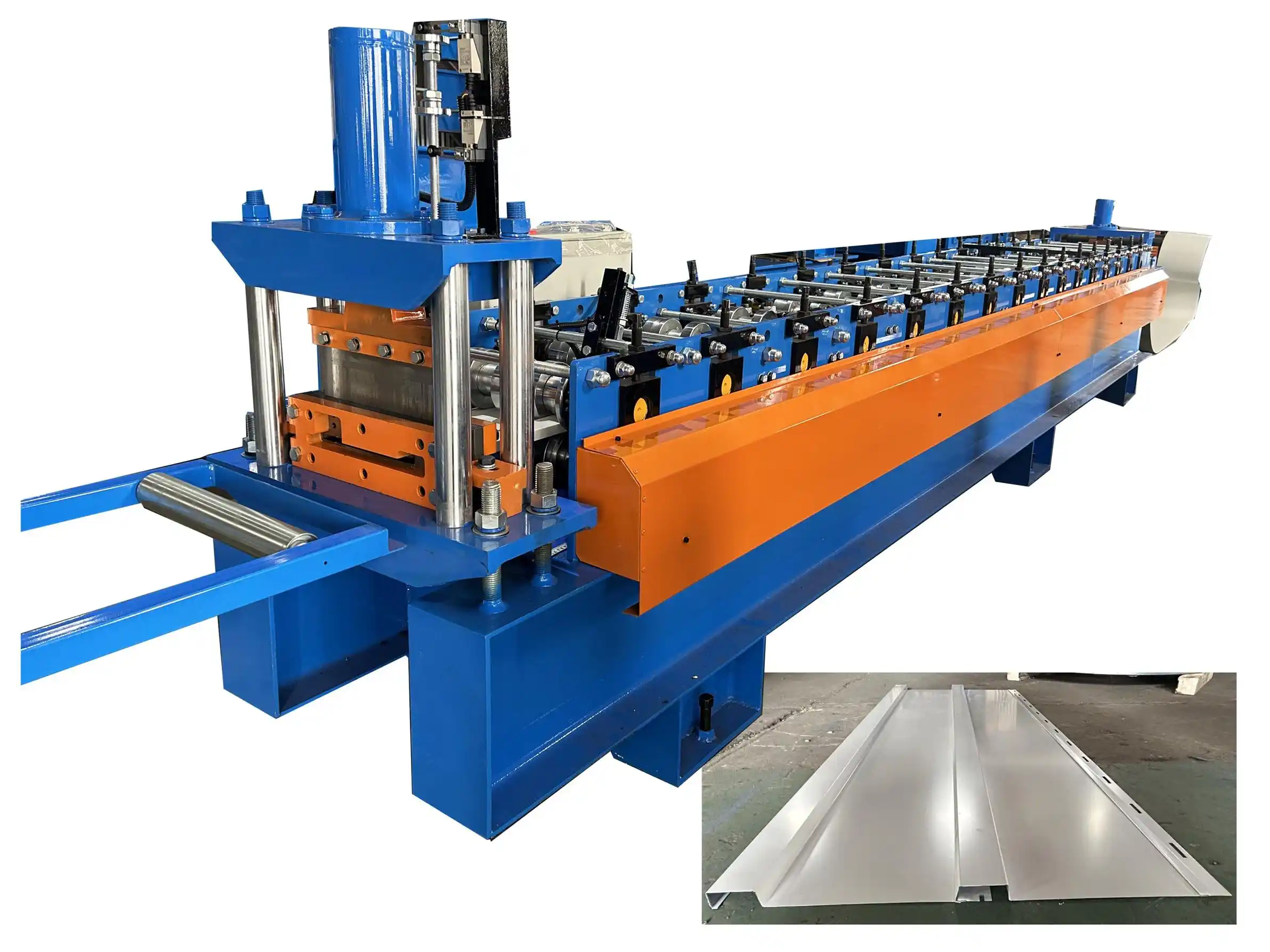

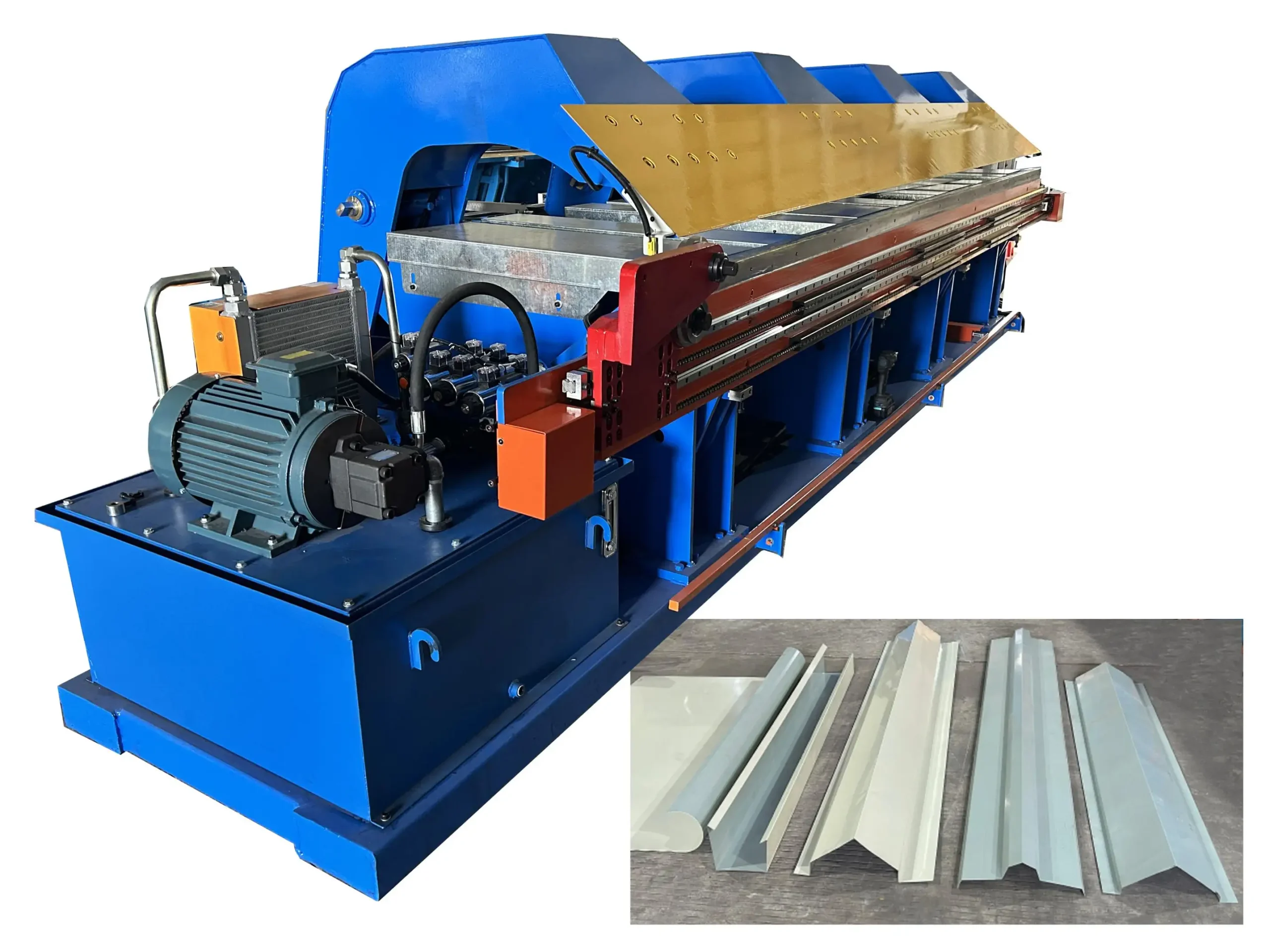

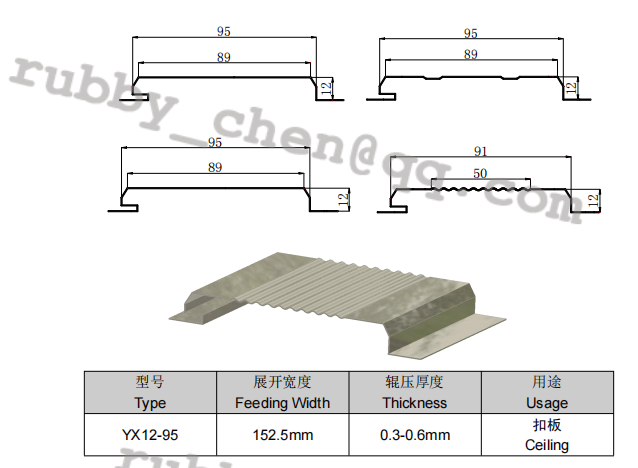

Spandrel makinesi profilleri

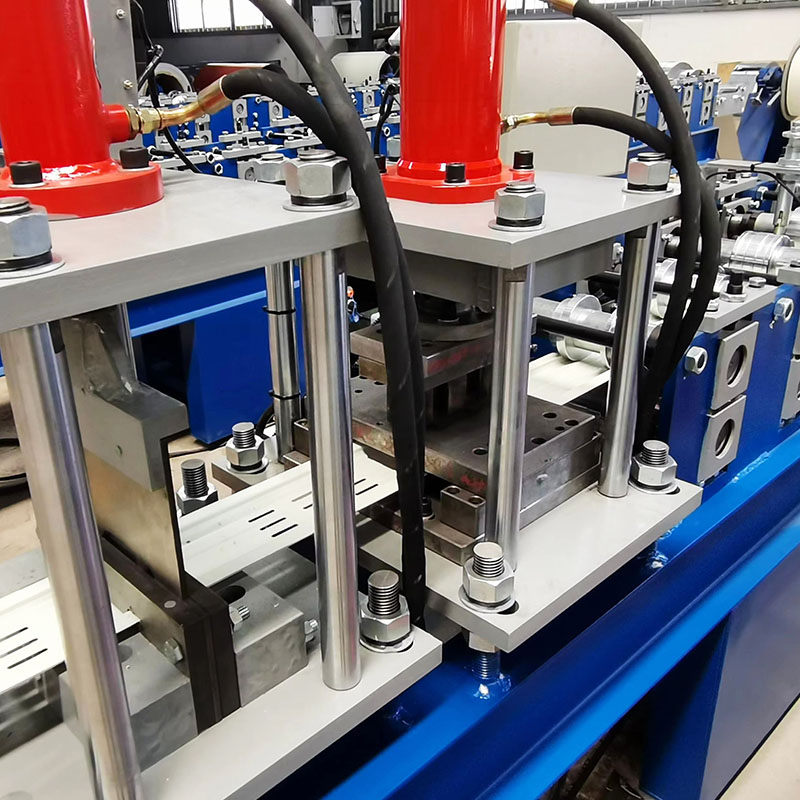

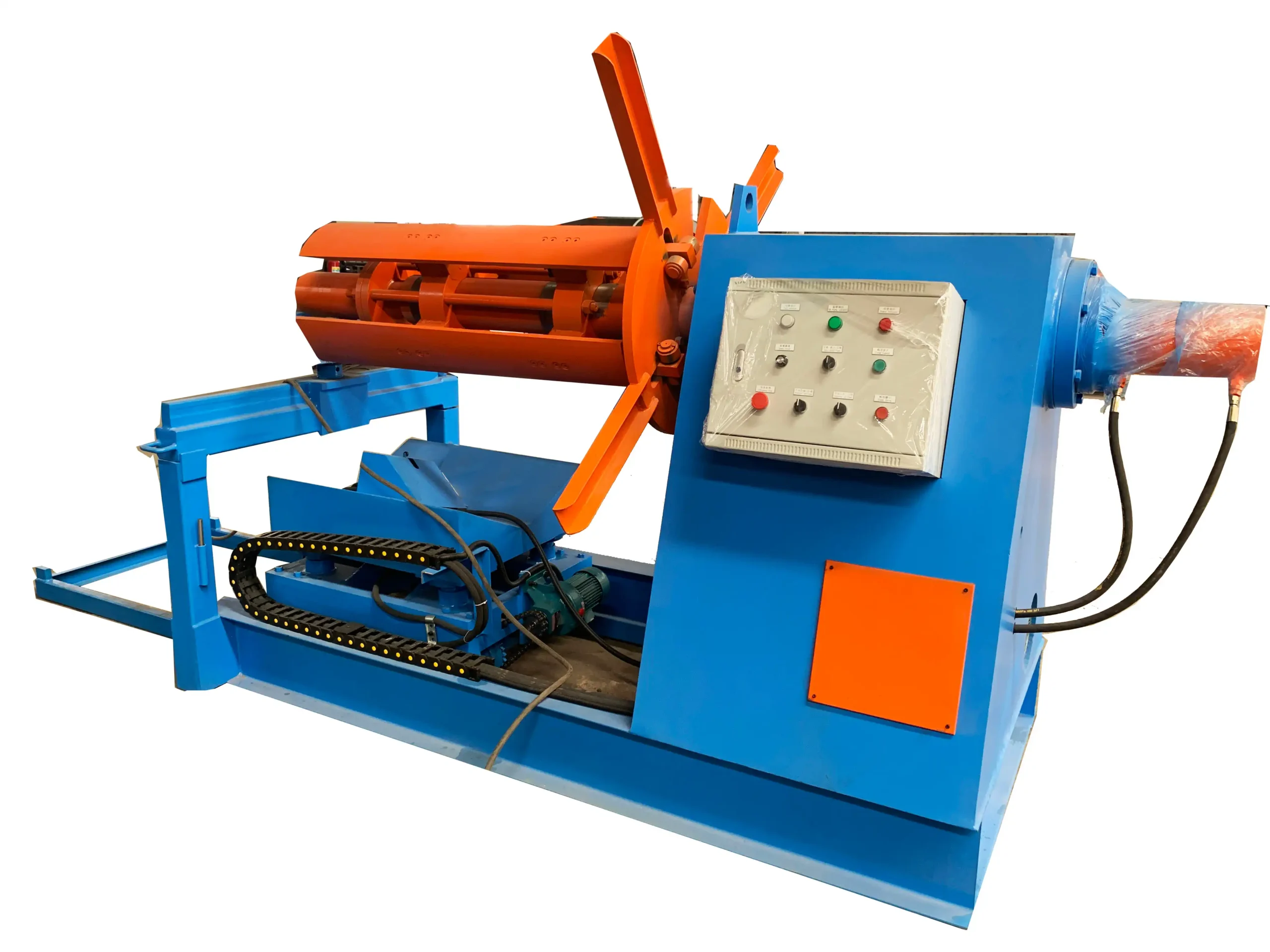

Spandrel makine bileşeni

Makine Parçaları

1) Besleme

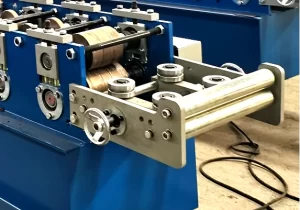

2) Rollers Makinenin

Silindirler yüksek kaliteli rulman çeliği GCr15'ten yapılmıştır, CNC tornalanmış, ısıl işlem görmüş ve sert krom kaplamalı olarak mevcuttur.

3) Şekillendirme kesici

4)PLC Kontrol sistemi (seçim için 2 tip)

Kullanımı kolay

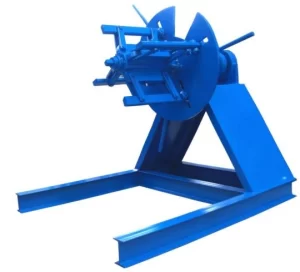

5)Decoiler (Seçim için 2 tip)

- Manuel çözücü 2. Hidrolik çözücü

Neden SKD'yi seçin Makine

- Geniş Selection: PU Köpük hattı, Hafif çerçeve makinesi e, CZ aşık makinesi ve her türlü rulo şekillendirme makinesi

- Kalite güvencesi :Ürün, titiz tasarım-yüksek standartlı işleme ve denetimden geçmiştir ve bitmiş ürün birçok kez test edilmiştir.

- Profesyonel Takım: Tasarım, Ar-Ge ve QC ekibinde 20 yılı aşkın deneyime sahip profesyonel bir ekibimiz var ve üretimdeki makinenin her adımını sıkı bir şekilde denetliyoruz.

- Endişesiz Hizmet:24 saat boyunca ihtiyaçlarınızı karşılayın ve makinelerimizin tüm ömrü boyunca teknik destek sağlayın.

- Garanti süresi: İşletmeye alma tarihinden itibaren 1 yıl içinde. Garanti, kolay aşınan parçalar hariç hattaki tüm elektrikli, mekanik ve hidrolik parçaları kapsar.

- Kolay kullanım: Tüm makineler PLC bilgisayar kontrol sistemi ile kontrol edilmektedir.

SSS

1. Spandrel Makinesi Nedir?

Spandrel Makinesi, inşaat sektöründe spandrel panelleri üretmek için kullanılan özel bir ekipman parçasıdır; bunlar tipik olarak bir kattaki bir pencerenin üstü ile üstündeki kattaki bir pencerenin altı arasında bulunan mimari unsurlardır.

2. Spandrel Makinesi hangi malzemelerle çalışabilir?

Spandrel Makineleri, belirli makineye ve yeteneklerine bağlı olarak cam, alüminyum ve kompozit paneller dahil olmak üzere çeşitli malzemelerle çalışabilir.

3. Bir Spandrel Makinesi nasıl çalışır?

Bir Spandrel Makinesi, hammaddelerin makineye beslenmesiyle çalışır ve burada önceden belirlenmiş spesifikasyonlara göre kesilir, şekillendirilir ve spandrel panellere monte edilir. Süreç tipik olarak hassas kesme, bükme ve bazen yapıştırma veya kaynak işlemlerini içerir.

4. Bir Spandrel Makinesinin temel özellikleri nelerdir?

Bir Spandrel Makinesinin temel özellikleri arasında yüksek hassasiyetli kesme aletleri, otomatik malzeme işleme, farklı panel tasarımları için özelleştirilebilir ayarlar ve verimli üretim hızları bulunur. Bazı makineler CNC kontrolü ve gerçek zamanlı izleme gibi gelişmiş özellikler de sunar.

5. Spandrel Makinesi kullanmanın faydaları nelerdir?

Faydaları arasında artan üretim verimliliği, tutarlı panel kalitesi, daha az malzeme israfı ve farklı tasarım özelliklerine hızlı bir şekilde uyum sağlama yeteneği bulunmaktadır. Bu makineler ayrıca üretim sırasında yüksek güvenlik standartlarının korunmasına yardımcı olur.

6. Bir Spandrel Makinesinin bakımını nasıl yaparım?

Bakım genellikle düzenli temizlik, hareketli parçaların yağlanması, aşınma ve yıpranma için kesme aletlerinin incelenmesi ve yazılım güncellemelerini içerir. Makinenin optimum performansını ve uzun ömürlülüğünü sağlamak için üreticinin bakım programını ve yönergelerini takip etmek önemlidir.

7. Bir Spandrel Makinesi özelleştirilebilir mi?

Evet, birçok Spandrel Makinesi belirli üretim gereksinimlerini karşılamak üzere özelleştirilebilir. Özelleştirmeler, farklı malzemeleri işlemek için modifikasyonları, kesme ve şekillendirme yeteneklerinde ayarlamaları ve diğer üretim hattı ekipmanlarıyla entegrasyonu içerebilir.

8. Spandrel Makinesi satın alırken nelere dikkat etmeliyim?

Makinenin malzemelerinizle uyumluluğu, üretim kapasitesi, kullanım kolaylığı, bakım gereksinimleri ve üretici tarafından sunulan teknik destek düzeyi gibi faktörleri göz önünde bulundurun. İlk yatırım ve uzun vadeli işletme maliyetleri dahil olmak üzere toplam sahip olma maliyetini değerlendirmek de önemlidir.

9. Bir Spandrel Makinesini kurmak ve kullanmaya başlamak ne kadar sürer?

Kurulum süresi, makinenin karmaşıklığına ve gereken özelleştirme düzeyine bağlı olarak değişebilir. Tipik olarak, bir Spandrel Makinesinin tam olarak kurulması, kalibre edilmesi ve kullanılmaya başlanması birkaç günden birkaç haftaya kadar sürebilir.

10. Spandrel Makinem için teknik desteği ve yedek parçaları nerede bulabilirim?

Teknik destek ve yedek parçalar genellikle makinenin üreticisi veya yetkili satıcıları aracılığıyla temin edilebilir. Gerektiğinde hızlı ve güvenilir destek sağlamak için tedarikçinizle iyi bir ilişki kurmanız önemlidir.