Прогонові профілегибочні машини CZ, широко відомі як швидкозмінні. Змінний верстат для виготовлення прогонів C/Z, також відомий як верстат для гнуття швелерів C&Z, виробляє профілі C і Z різних діаметрів і товщини, які можна штампувати як з боку прогону, так і з боку фланця.

Специфікація

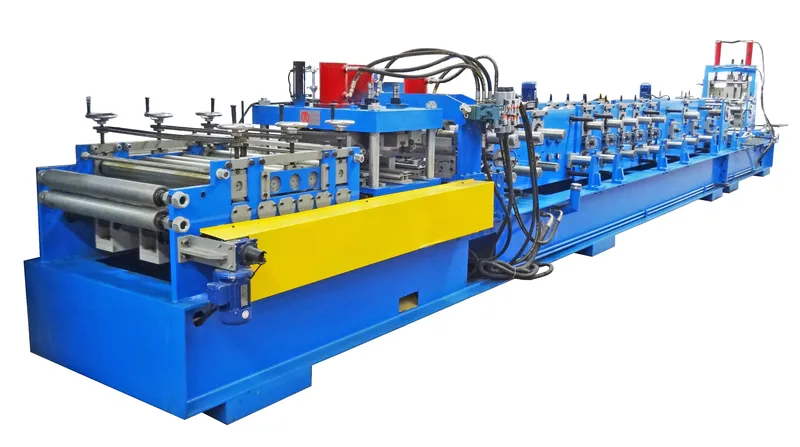

- Інтегрований бар'єр CZ - це вдосконалена машина для пресування плитки, яка поєднує в собі машину С-типу і машину Z-типу, що має переваги обох машин і обладнання. Цей пристрій може не тільки підвищити ефективність роботи, але і знизити виробничі витрати. Основні особливості інтегрованої совкової машини CZ включають різання і не вимагають заміни інструментів, швидку заміну (три хвилини довільної заміни), регульовану (можна виконати черевце, край крила і край крила), регульовану (можна виконати черевце, край крила і край крила). ), триступенева заміна CZ, а також конструкція загальної осі (зменшена висота двох сторін зламаної осі).

- Інтегрована черпакова машина CZ в основному складається з пасивних стелажів подачі, плоского пристрою, штампувального пристрою, відрізного пристрою після формування, гідравлічних станцій, комп'ютерних систем управління і т.д., в якій використовується автоматичне штампування мухобойкою, а експлуатація проста. Сталеві сандалові смуги C і Z, вироблені цим пристроєм, використовуються сталевими пластинами за допомогою холодного тиску, що має характеристики рівномірної товщини стінки, регульованого розміру та високої стійкості до тиску. Крім того, сталеві сандалові смуги C і Z легкі і низькі, а вартість проста. Конструкція проста. Він може безпосередньо відрізати довжину смуги сандалового дерева з переробного заводу, а потім транспортувати її безпосередньо на будівельний майданчик.

Компоненти машин:

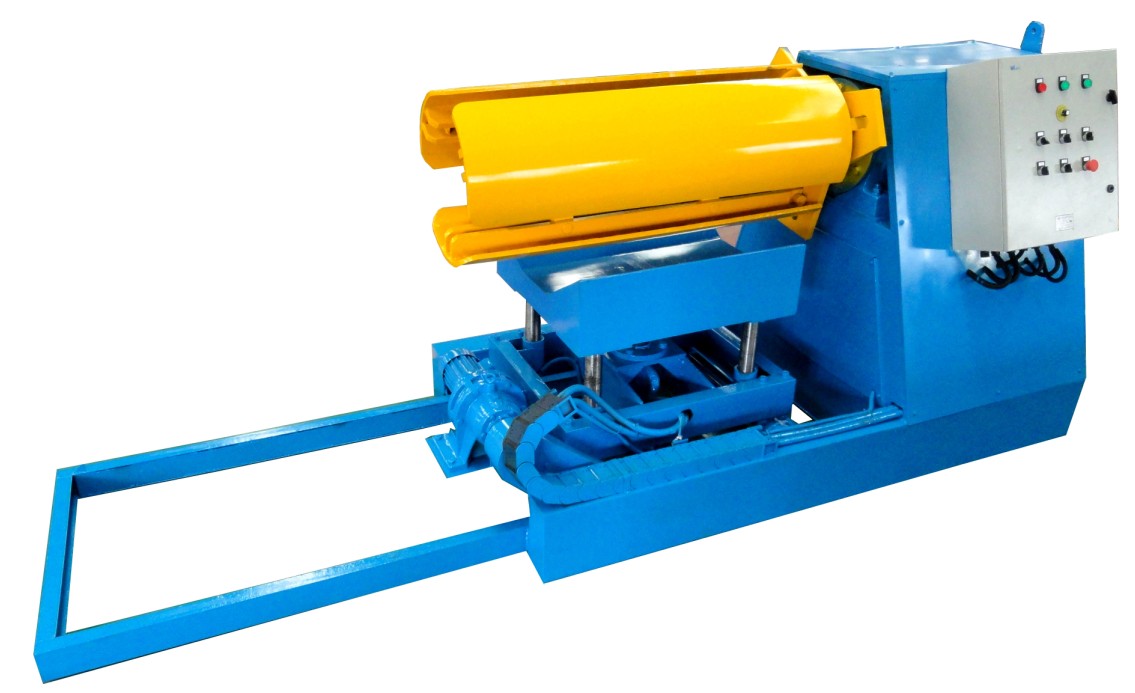

- Подача та вирівнювання прогону CZ Purlin: Цей етап має важливе значення для підготовки матеріалу перед тим, як він потрапляє в процес формування рулонів. Він гарантує, що матеріал вирівняний і підготовлений до наступного етапу.

- Обладнання для попередньої перфорації: За допомогою цього обладнання на плиті пробиваються отвори. Воно точно розраховує кількість і горизонтальне розміщення пуансонів під контролем ПЛК. Хоча вертикальне положення можна регулювати вручну, кількість і розмір отворів можна підбирати відповідно до потреб клієнта.

- Пристрій для попереднього різання: Перед вальцюванням матеріал повинен бути розрізаний до відповідних пропорцій. Цю роботу ефективно виконує обладнання для попереднього різання, гарантуючи належну підготовку матеріалу до подальших процедур.

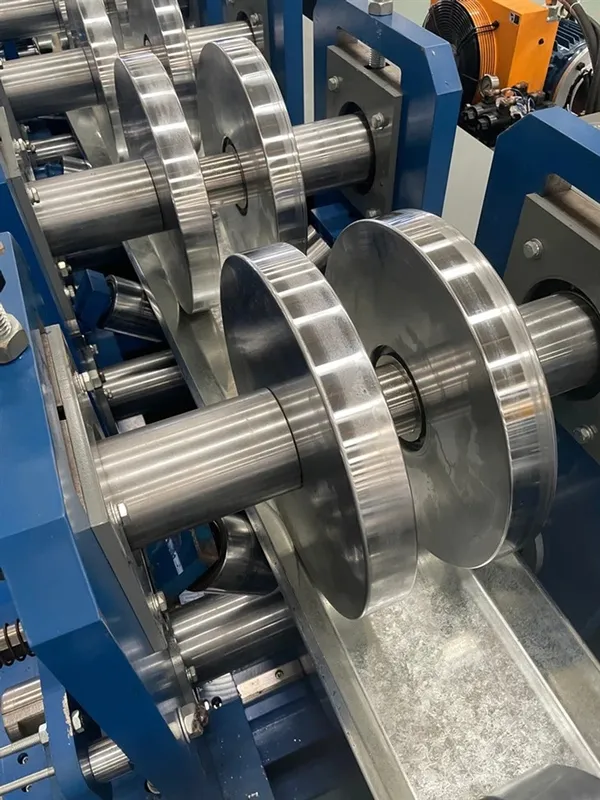

- Обладнання, відоме як універсальне формувально-розкрійне обладнання, є важливою складовою всього процесу, оскільки воно відповідає за формування та розкрій матеріалу до необхідних розмірів. Воно гарантує, що готовий продукт відповідає найвищим стандартам якості та точності, поєднуючи в собі ефективність і точність.

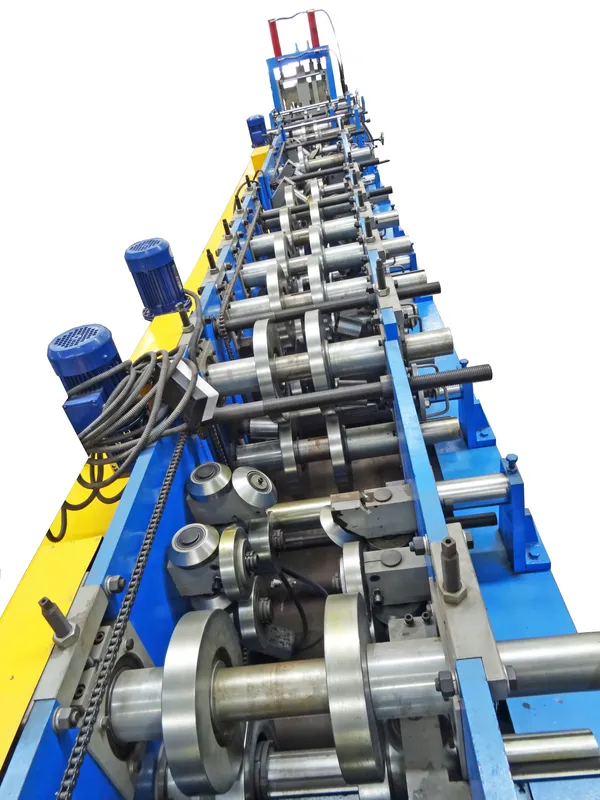

- Основна машина CZ Purlin: Це центральний компонент процесу, де сировина перетворюється на готову продукцію. Міцна конструкція і складні функції дозволяють йому працювати з широким спектром матеріалів і ефективно виробляти прогони CZ найвищої якості.

Ключові особливості та застосування:

- Система швидкої заміни: Завдяки цій системі машина може швидко змінювати валковий інструмент або форму, щоб задовольнити потреби у виробництві С- і Z-подібної обрешітки різноманітних розмірів і форм. Це значно підвищує універсальність обладнання та ефективність виробництва.

- Виробництво C/Z профілів: На цьому верстаті можна виготовляти металеві прогони у формі С і Z з різною товщиною і діаметром. Прогони є важливими елементами для підтримки, з'єднання і зміцнення будівель, і вони широко використовуються у виробництві, будівництві та інших галузях.

- Можливість пробивання: Прогонові вальцювальні верстати CZ часто оснащені можливістю пробивання, що дозволяє пробивати полотно або фланець прогону. Це задовольняє певні технічні вимоги і дає споживачам більше альтернативних варіантів дизайну.

- Висока точність і стабільність: Висока точність і стабільність прогонів може бути гарантована завдяки технології роликового формування. Машина здатна створювати прогони точних розмірів і правильної форми, щоб задовольнити різноманітні технічні стандарти та вимоги завдяки точному проектуванню та виготовленню прес-форм.

- Автоматизація та інтелект: Більшість сучасних прогоновочних верстатів CZ оснащені складними системами автоматизації та інтелектуальними системами управління. Ці технології дозволяють контролювати і змінювати виробничий процес в режимі реального часу, гарантуючи стабільність і надійність як ефективності виробництва, так і якості продукції.

- Численні сфери застосування: Завдяки своїм відмінним конструктивним характеристикам і численним сферам застосування, прогони С- і Z-типу широко застосовуються в обробній, транспортній і будівельній галузях, а також в інших сферах. Завдяки впровадженню вальцювальних верстатів для прогонів CZ ми пропонуємо більш гнучкі та економічні виробничі рішення для різних галузей.

Основні переваги профілегибочного верстата для прогонів CZ:

Ефективність виробництва значно підвищується завдяки здатності вальцювального верстата CZ швидко і безперервно створювати прогони С- і Z-образного типу. Продуктивний метод формування валків дозволяє швидко виконати велику кількість роботи, скорочуючи час виробництва.

- Гнучкість: Ці машини часто оснащені механізмом швидкої заміни прокатних інструментів або форм, що дозволяє швидко замінити або виправити прогони різних розмірів і форм. Завдяки своїй адаптивності машина може скоротити час переналагодження виробництва і пристосуватися до змін ринкового попиту.

- Висока точність: Завдяки точному проектуванню та виготовленню прес-форми машина для формування прогонів CZ може виготовляти прогони точних розмірів і правильної форми. Це сприяє дотриманню суворих технічних стандартів і норм, а також гарантує якість готової продукції.

- Високий коефіцієнт використання матеріалу: Технологія вальцювання дозволяє мінімізувати відходи та максимально використовувати сировинні ресурси. Завдяки точному управлінню процесом формування, машина може гарантувати ефективне використання матеріалу і мінімізувати виробничі витрати.

- Функція пробивання: Функція пробивання - це ще одна функція, яку мають багато профілегибочних верстатів CZ. Ця функція дозволяє пробивати отвори в прогоні з боку полотна або фланця. Це задовольняє певні технічні вимоги і дає споживачам більше альтернативних варіантів дизайну.

- Високий ступінь автоматизації: Більшість сучасних верстатів для формування прогонів CZ оснащені дуже складними автоматизованими системами управління, які дозволяють здійснювати моніторинг і модифікацію виробничого процесу в реальному часі. В результаті виробничий процес є більш стабільним і надійним, вимагає менше ручної праці та зменшує кількість людських помилок.

- Простий догляд та обслуговування: Ці пристрої часто мають просту в обслуговуванні конструкцію, що забезпечує довготривалу та стабільну роботу. Часте технічне обслуговування і ремонт можуть продовжити термін служби і продуктивність машини, знижуючи при цьому рівень відмов.

- Енергозбереження та захист навколишнього середовища: Прогонові вальцьові верстати CZ відповідають нормам захисту навколишнього середовища, виробляючи менше відходів і шуму під час виробництва. Ефективне використання енергії одночасно знижує виробничі витрати та споживання енергії.

Сценарій застосування профілегибочного верстата CZ для виготовлення прогонів

У будівельному секторі прогони С- і Z-образного типу часто використовуються в якості опорних і підсилюючих конструкцій для мостів і доріг. Верстат для формування прогонів CZ здатний точно і швидко виготовляти прогони, які відповідають специфікаціям.

- Будівництво будинків: Прогони типу C і Z використовуються в будівництві як несуча конструкція для даху, стін і перегородок. За допомогою вальцьових верстатів CZ можна виконувати різноманітні архітектурні проекти.

- Об'єкти, пов'язані з сільським господарством: виноградні альтанки, садові стовпчики, теплиці для овочів і т.д. Як несучі конструкції, ці об'єкти потребують великої кількості С- і Z-прогонів, які можна швидко і у великій кількості виготовити за допомогою вальцювального верстата для прогонів CZ.

- Промисловий завод: Щоб задовольнити будівельні вимоги промислових підприємств, прогонова машина CZ може виготовляти прогони С і Z з різними технічними характеристиками і довжинами. Заводи з великими прольотами потребують міцних опорних конструкцій.

- Механічне обладнання: Прогонова машина CZ може надавати індивідуальні виробничі послуги; певне механічне обладнання потребує С- і Z-прогонів в якості кронштейнів або з'єднань.

- Транспортна галузь: Залізничні об'єкти, такі як залізничні мости і тунелі, потребують використання прогонів С- і Z-образного профілю в якості арматури і опорних конструкцій. Високий попит на прогони на цих об'єктах може бути задоволений за допомогою профілегибочного верстата CZ.

- Виробництво автомобілів: Для різних транспортних засобів (наприклад, вантажних автомобілів, спеціальних транспортних засобів і т.д.) потрібні С-образні і Z-образні прогони в якості компонентів кузова або рами. За допомогою вальцювального верстата для виготовлення прогонів CZ можна виготовляти високоякісні вироби з прогонів.

- Складські приміщення: Прогони С-типу і Z-типу потрібні для опорних і з'єднувальних конструкцій, таких як стелажі, контейнери тощо. За допомогою профілегибочного верстата CZ можна виготовити прогони, необхідні для цих об'єктів.

- Об'єкти охорони навколишнього середовища, в тому числі очисні споруди та станції утилізації сміття, потребують використання прогонів С- і Z-образного профілю в якості опорних і підсилюючих конструкцій. Прогонові профілегибочні верстати компанії "CZ" можуть забезпечити ці об'єкти необхідними матеріалами для прогонів.