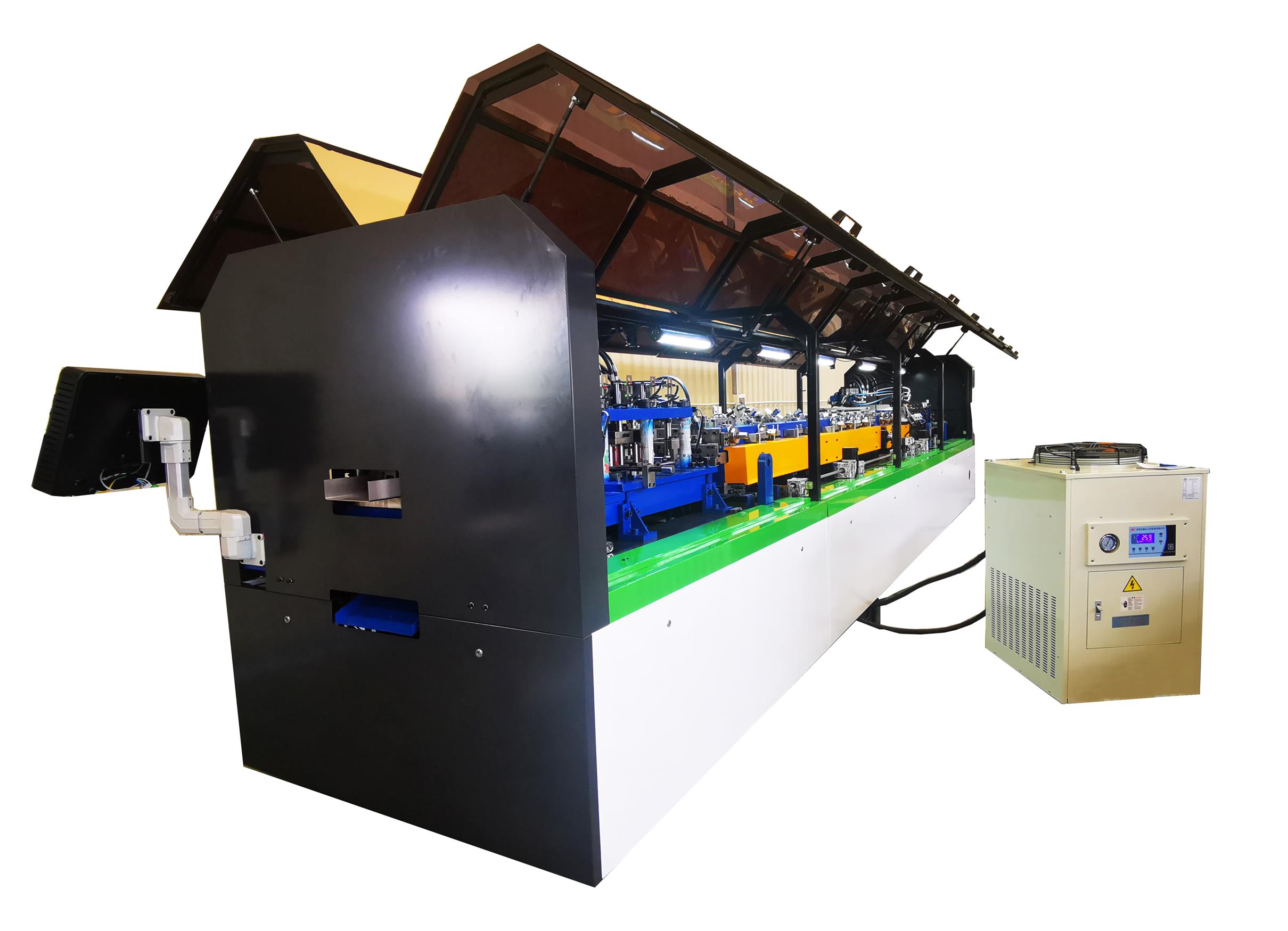

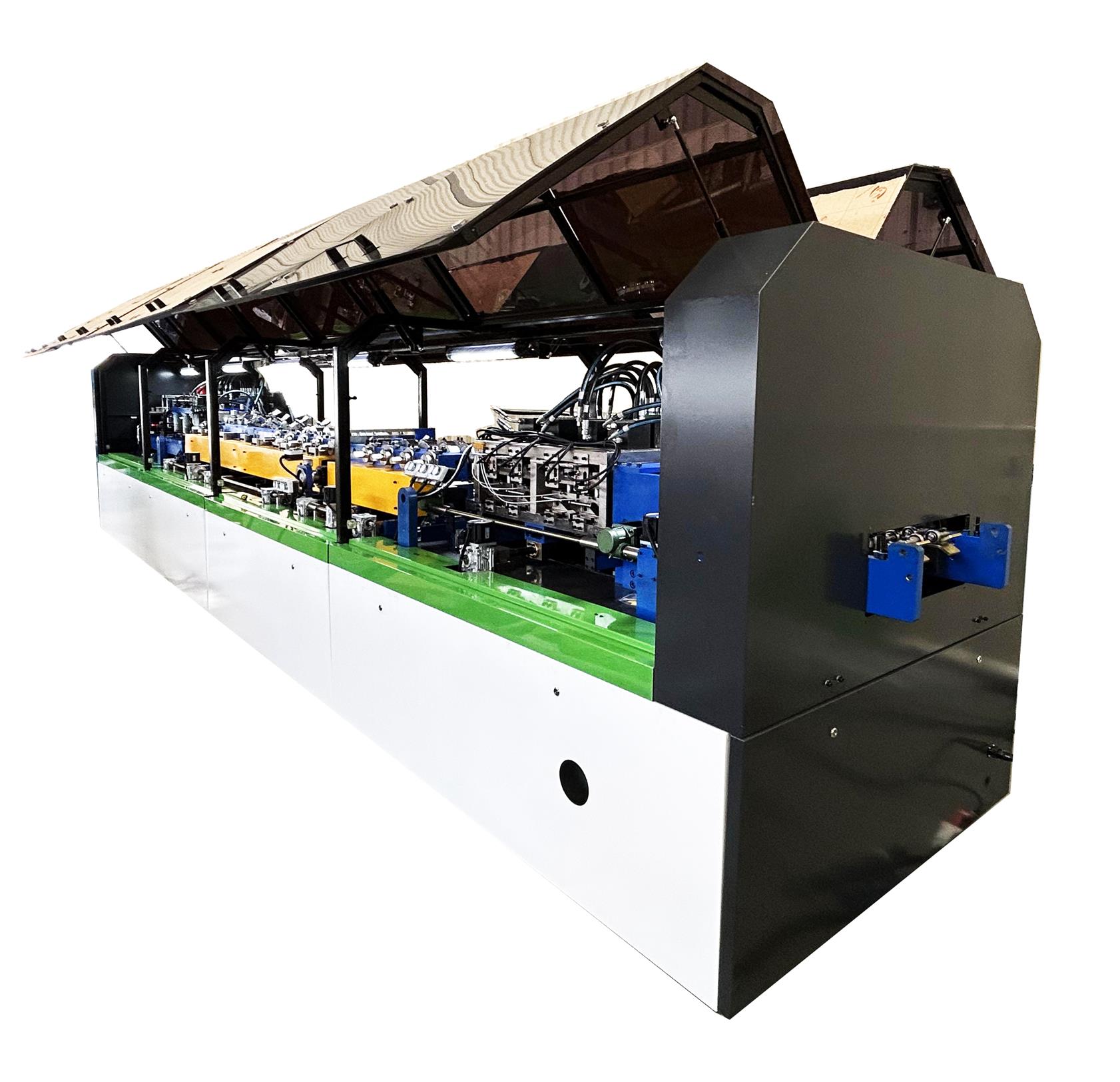

Insulation Sandwich Panel Machines Description

Машина для виробництва ізоляційних сендвіч-панелей - це ефективне виробниче обладнання, спеціально розроблене для безперебійного виробництва високоякісних високовольтних сендвіч-панелей. Ці сендвіч-панелі широко використовуються в промисловості завдяки своїм чудовим ізоляційним характеристикам і довговічності, і широко застосовуються в багатьох галузях, таких як будівництво, холодильне обладнання, промислове обладнання тощо.

The main components of insulating sandwich panels include polyurethane (PU) or polyisocyanurate (PIR), both of which are known for their excellent thermal insulation, heat insulation and fire resistance. Polyurethane materials have the characteristics of light weight, high strength and low thermal conductivity, which can effectively isolate the external cold and hot temperatures and maintain the stability of the internal environment. Polyisocyanurate (PIR) is a more advanced material. While maintaining the advantages of polyurethane, it also has better fire resistance, which can greatly improve the safety performance of sandwich panels.

Specification of Sandwich Panel Machine

- High degree of automation: The production line is equipped with an innovative automatic control system, which can realize the automation of the whole process from raw material delivery to product molding. This high degree of automation not only improves production efficiency, but also ensures the stability and consistency of product quality.

- Rapid foaming with high pressure technology: The production line uses high pressure technology to rapidly foam polyester materials such as polyurethane (PU) or polyisocyanurate (PIR). This technology makes the sandwich panel have better insulation effect, while reducing energy consumption and improving energy utilization efficiency.

- Accurate metering and temperature control system: The production line is equipped with a precise metering and temperature control system, which can ensure that the parameters of each production link are controlled within the optimal range. This ensures the consistency and stability of product quality and meets customers’ demand for high-quality sandwich panels.

- Focus on safety and environmental protection: The production line fully considers safety and environmental protection factors in its design, and adopts a low-pollution and low-emission production process. At the same time, a comprehensive safety procedure is implemented to ensure employee safety and environmental protection during the production process. This design concept is in line with the current green and low-carbon production trend and helps enterprises achieve sustainable development.

Profiles and flow chart of Polyurethane panel foam machine

The Pics of Sample And Project: