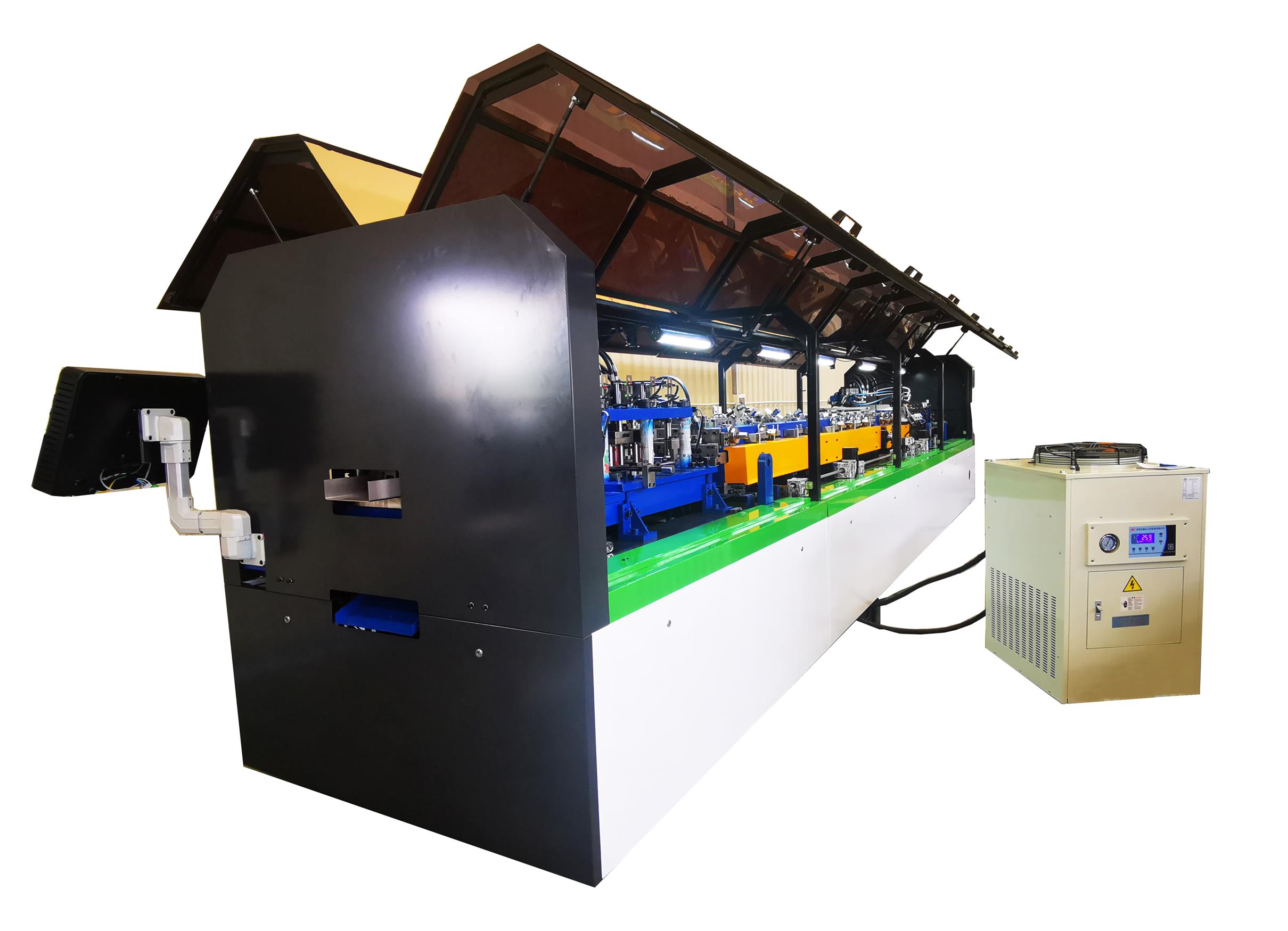

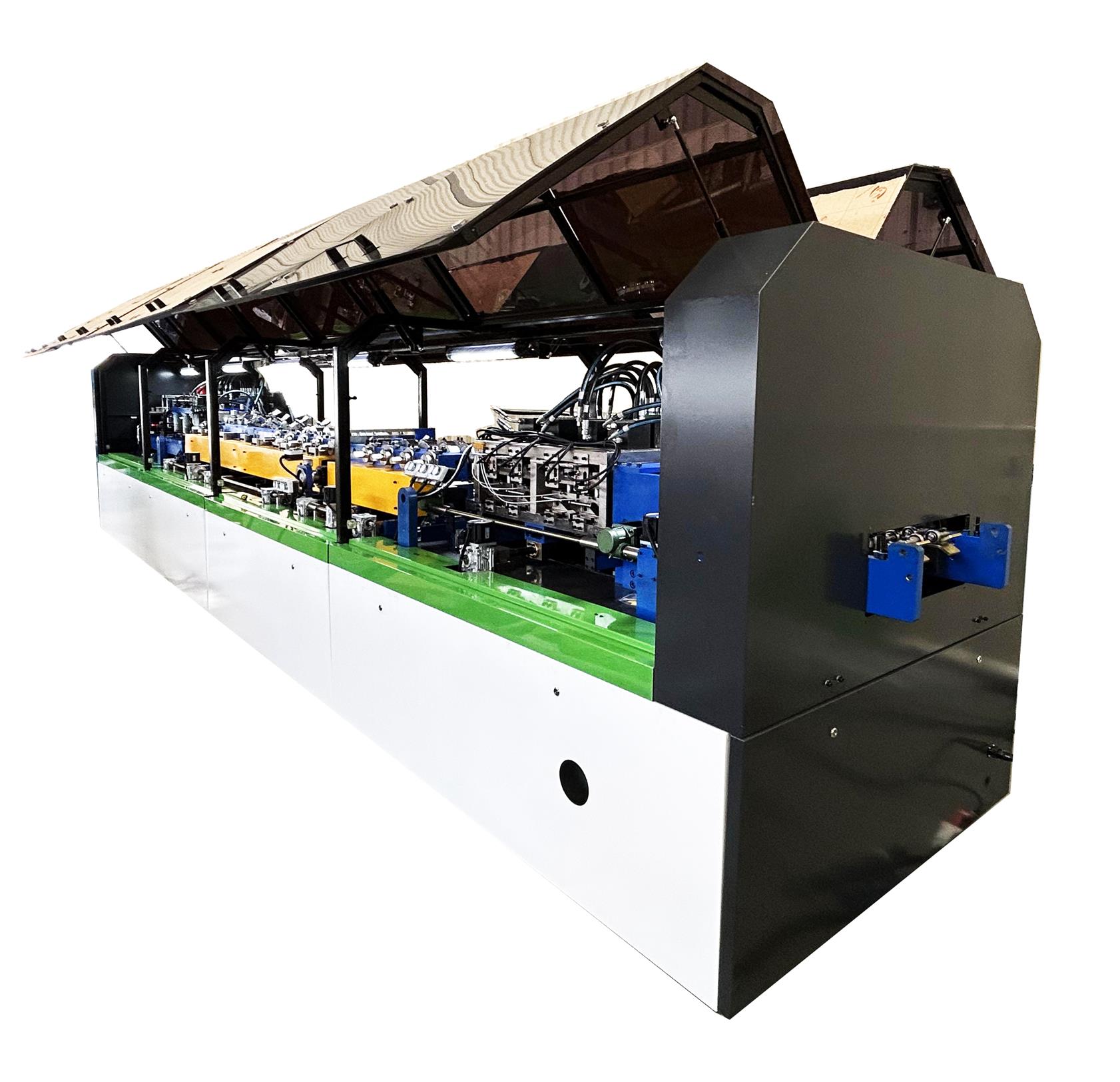

Introduction of Metal Roofing Forming Machine

Metal Roofing Forming Machines, as indispensable and important equipment in modern construction, have become a key force in promoting the development of the construction industry with their advanced technology and efficient production capacity. This equipment can produce high-rigidity, lightweight, easy-to-install, and durable metal roof panels, which are widely used in various construction projects such as industrial buildings, agricultural facilities, and residential buildings. Its outstanding performance and unique advantages make it occupy a pivotal position in today’s construction field.

Excellent rigidity: a solid barrier against extreme weather

One of the biggest advantages of the roof panels produced by Metal Roofing Forming Machine is their excellent rigidity. These roof panels can remain stable and intact under extreme weather conditions such as storms, strong winds, and snow, becoming a solid protective barrier for buildings. The high rigidity of the roof panels not only enhances the safety of the building but also extends the service life of the roof, allowing the building to maintain stability during long-term use.

More importantly, metal materials have natural corrosion resistance, which can effectively resist acid rain, ultraviolet rays, and other factors in the environment, delaying the aging and damage of materials, thereby greatly extending the service life of the roof panels and reducing long-term maintenance costs.

Lightweight design: improve construction efficiency

Another highlight of the Metal Roofing Forming Machine is that the roof panels it produces are lightweight. This lightweight design not only significantly reduces the overall weight of the building and reduces the burden on the building structure but also speeds up the construction progress. Compared with traditional roofing materials, metal roof panels are lighter and easier to install, which can effectively shorten the construction period.

This lightweight design not only improves the safety of the building but also makes the construction process more efficient. Whether it is a new project or a renovation project, the roof panels produced by the Metal Roofing Forming Machine can save a lot of time and labor costs for the project, and promote the construction industry to develop in the direction of efficiency and environmental protection.

Easy installation: accurate and efficient

The Metal Roofing Forming Machine adopts automatic control technology, which can accurately control the size and specifications of the roof panels to ensure that the production accuracy of each roof panel meets the standard requirements. Thanks to this precise control, construction personnel can quickly and accurately complete the installation of the roof panels according to the design drawings, greatly improving the on-site construction efficiency and reducing the errors caused by manual operation.

In addition, the accuracy of the metal roof panel also ensures the beauty of the roof, so that every detail meets the design requirements and improves the quality and appearance of the overall building. Simple installation processes and efficient construction methods are the basis for the rapid development of modern architecture.

Super durability: low maintenance cost

The roof panels produced by Metal Roofing Forming Machine have extremely strong durability, which makes them unparalleled competitive in the market. These roof panels are made of high-quality metal materials and processed with exquisite craftsmanship. They are not only wind-resistant, rain-proof, and UV-resistant, but also can be used for a long time in various harsh environments.

Compared with traditional roofing materials, metal roof panels do not require frequent maintenance or replacement, which greatly reduces the maintenance cost in long-term use. This ultra-long service life and low maintenance cost provide a more economical choice for enterprises and families.

Environmental protection and sustainable development: the first choice for green buildings

The production process of Metal Roofing Forming Machine is not only efficient and low-cost, but also the roof panels they produce are in line with the concept of modern green buildings. First of all, metal materials themselves have strong recycling and reuse capabilities, which is in line with the development trend of the circular economy. Secondly, the durability and corrosion resistance of metal roof panels makes them not need frequent maintenance or replacement during use, reducing the waste of resources and promoting the sustainable development of the construction industry.

Roof panels produced by Metal Roofing Forming Machines can not only reduce the long-term operating costs of building but also help to achieve optimal use of resources and reduce the burden on the environment.

Workflow of Metal Roofing Forming Machine

The production process of the Metal Roofing Forming Machine consists of multiple links, each of which is carefully designed to ensure the quality and functionality of the final product:

- Uncoiler: uncoils the raw material coil steel plate and prepares it to enter the production line;

- Feed guide device: ensures that the steel plate is smoothly fed into the next link in the predetermined direction;

- Pre-shearing device: pre-cuts and adjusts the steel plate as needed;

- Rolling forming system: forms the target waveform through multiple rollers;

- Hydraulic post-shearing device: accurately shears through the hydraulic system to ensure the size of the roof panel;

- Discharging rack: finally stack the formed roof panels according to demand.

Робочий процес

Розмотувач→Пристрій подачі→Пристрій попереднього різання→Система формування рулону→Гідравлічний пристрій пост-різання→Вихідний стелаж

This production process ensures the accuracy and stability of each roof panel, which can meet the different requirements of various construction projects for roof panels.

Технічні параметри машини

| Ні. | Пункт | Параметр |

| 1 | Розмір машини | 7200*1500*1600mm |

| 2 | Вага машини | 5000kg |

| 3 | Потужність машини | 5,5 кВт |

| 4 | Гідравлічний двигун | 2,2 кВт |

| 5 | Швидкість рулону | 0-20m/min |

| 6 | Рулонні станції | 14 |

| 7 | Матеріал ролика | 45#Steel |

| 8 | Ефективна ширина | індивідуальний |

| 9 | Ширина подачі | 914mm |

| 10 | Напруга | 380В 50Гц 3PH / На замовлення |

| 11 | Товщина матеріалу | 0.35-0.65mm/Customized |

| 12 | Система управління | Schneider/Delta/Customized |

Wide application of Metal Roofing Forming Machine

Roof panels produced by Metal Roofing Forming Machine are widely used in the construction industry. Metal roof panels play an important role in large buildings such as industrial plants and warehouses, as well as in residential and agricultural facilities. Especially under the requirements of modern buildings for high efficiency, environmental protection, and energy saving, metal roof panels have become the preferred material due to their lightness and durability.

The Metal Roofing Forming Machine not only represents the technological progress of the construction industry but also is a key equipment to promote the innovation of modern building materials. The roof panels it produces have multiple advantages such as high rigidity, lightness, durability, and environmental protection, which can meet the high requirements of various construction projects for materials. With the continuous innovation of technology, Metal Roofing Forming Machines will continue to play an important role in improving building quality, reducing construction costs, and promoting green buildings.