Light Steel Framing Machine Manufacturer

Specifications of Light Steel Framing Machine

Raw ingredients and manufacturing volume:

This model can adapt to raw materials of varied specifications, guaranteeing that the steel structure frame produced is precise and diversified in size to satisfy a variety of architectural and design needs.

The manufacturing size is highly customizable and can be precisely modified to meet client particular needs, resulting in efficient and accurate production output.

| Profile Dimension:C89x41x9mm; |  |

| Raw Material: G300-G550 GI/GL strip; | |

| Thickness Range:0.75-1.2mm; | |

| Material Width:C≈180mm; |

Machine Speed:

Maximum manufacturing speed is 48 meters per minute (excluding post-processing time such as cutting and punching). This speed indication emphasizes the model’s exceptional performance, which allows it to do a huge number of manufacturing activities quickly.

Because of its high production speed, the steel structure frame machine can react rapidly to market demand, reduce delivery cycles, and offer strong support for large-scale manufacturing projects. Simultaneously, efficient manufacturing capacity lowers the cost per unit output and improves firm competitiveness.

Profile:

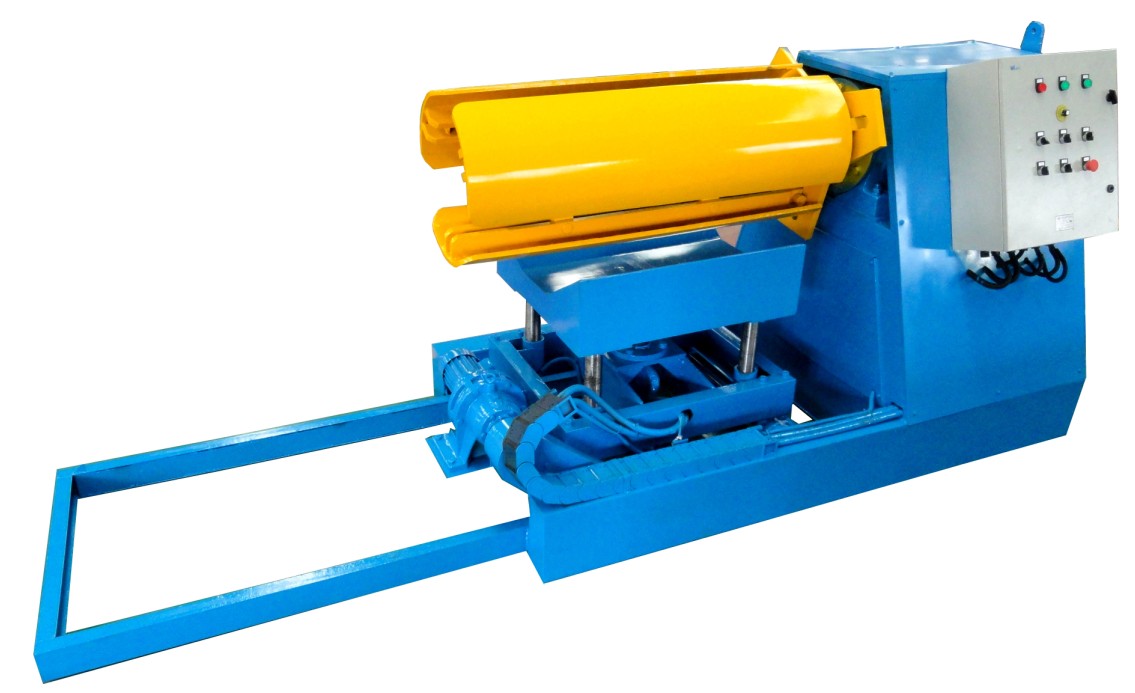

Technical specifications of the uncoiler

With its extensive technical characteristics and strong functional design, this uncoiler is suitable for a broad range of coil uncoiling activities, offering effective and dependable equipment support for metal processing, machinery production, and other sectors.

- Core Functions:

Equipped with an automated start and stop mechanism for intelligent operation control.

Use a variable frequency motor drive to guarantee smooth operation and minimal energy usage.

- Material specifications:

Strip width: maximum support 400mm, meets a variety of width specifications.

Coil outer diameter: up to 1300mm, suitable for coils of various diameters.

Inner diameter of the material: 450-530mm, allowing it to accommodate coils with varying inner hole sizes.

Material width adjustment range is 50-500mm, allowing a broad variety of width selection options.

- Load Performance:

Rated load: 3 tons, having a high load-bearing capability for reliable operation.

- Drive configuration:

The main motor has a power output of 1.5 kilowatts, which is adequate for efficient manufacturing.

Technical parameters of hydraulic cutting and punching die

Construction projects: