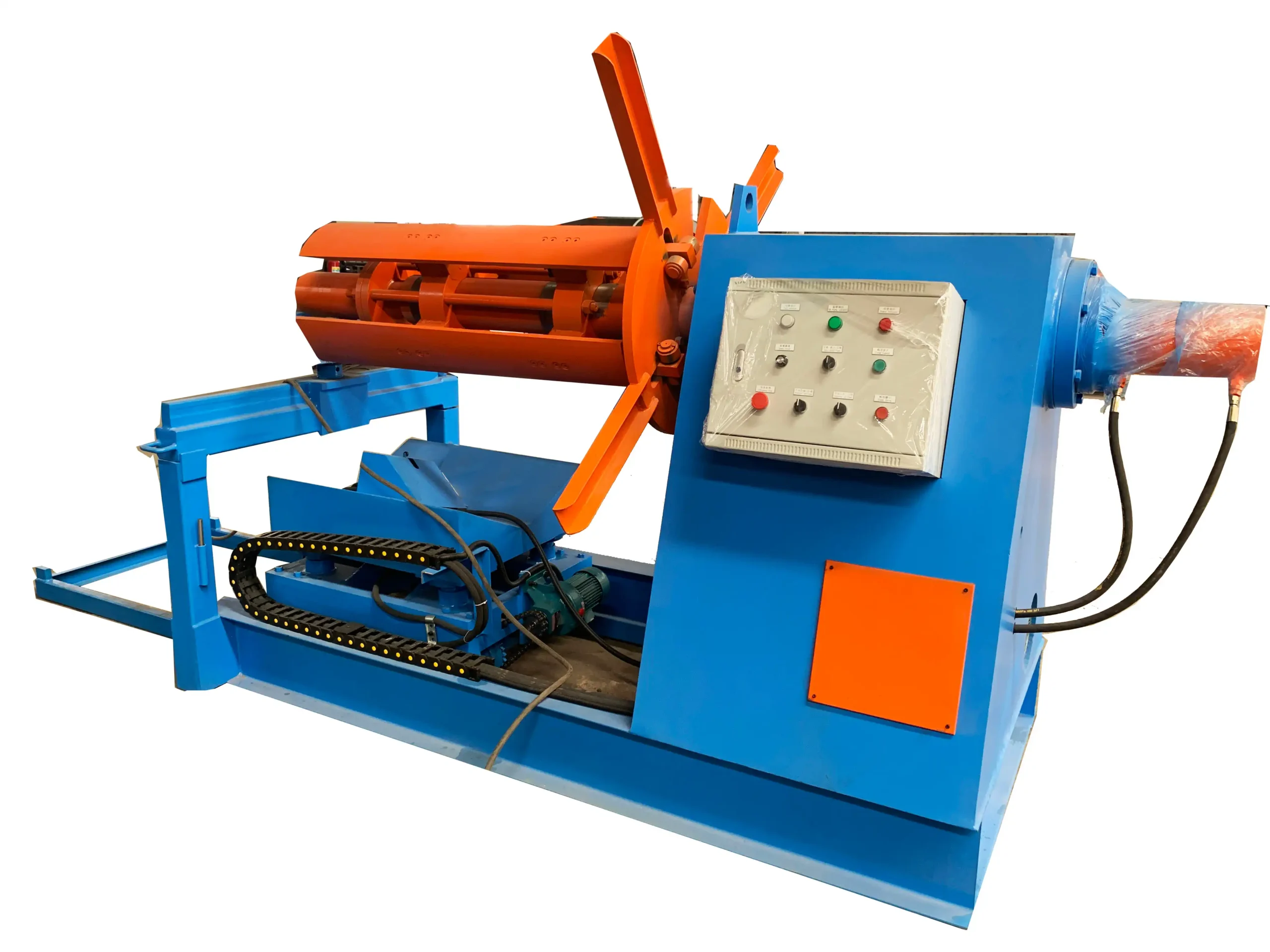

C75-200 Multifunktionel maskine til lette stålrammer Funktioner

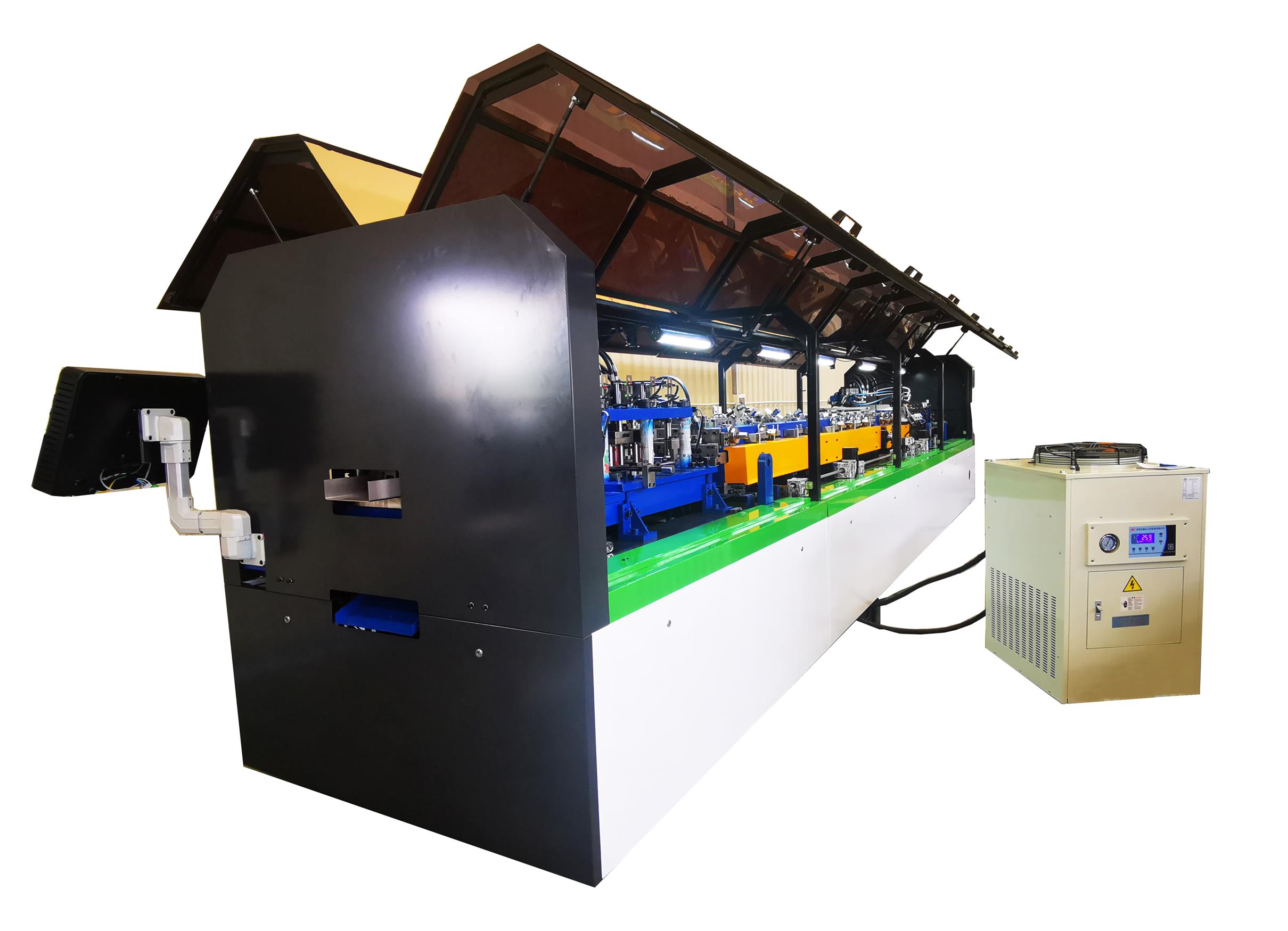

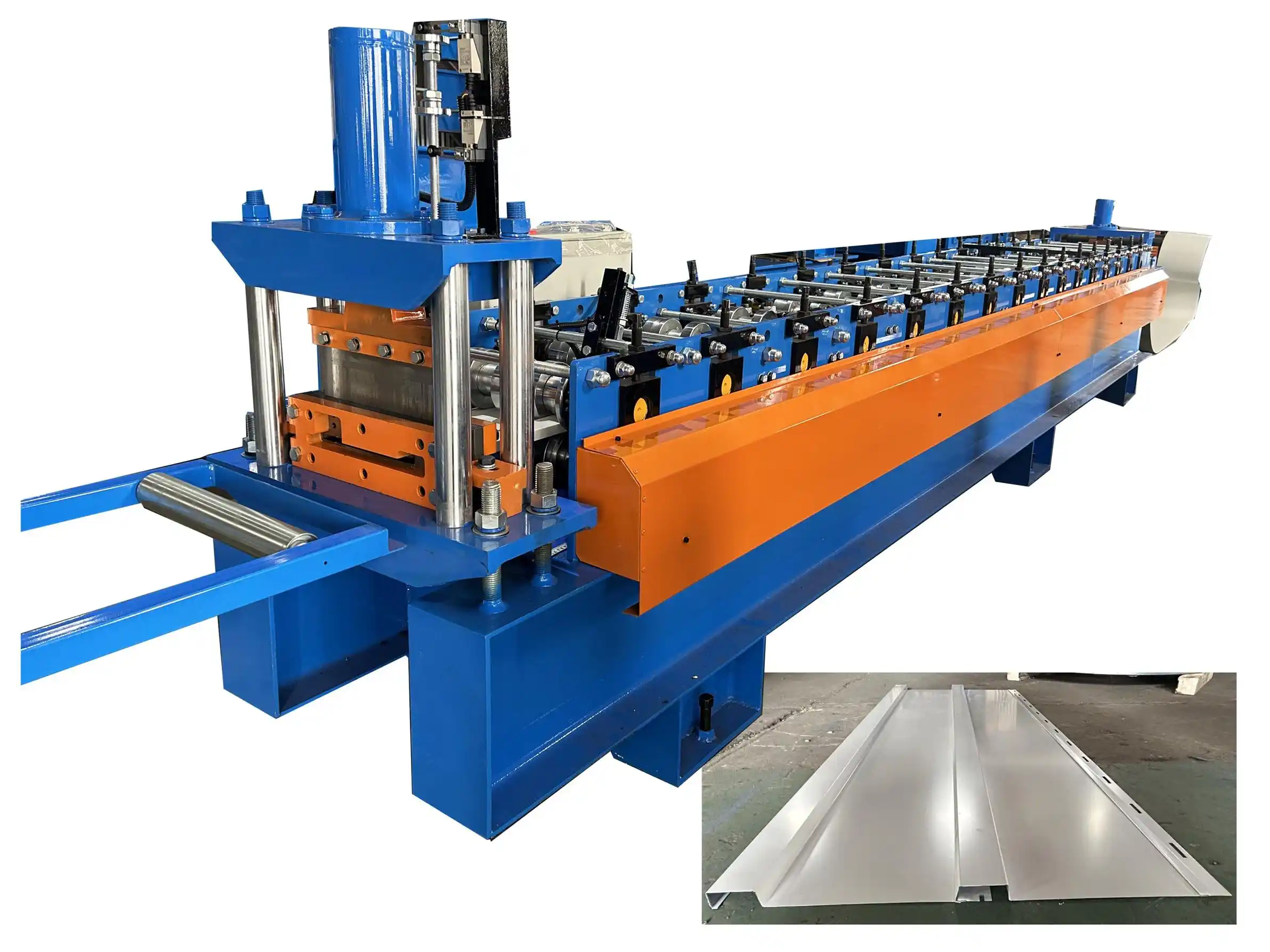

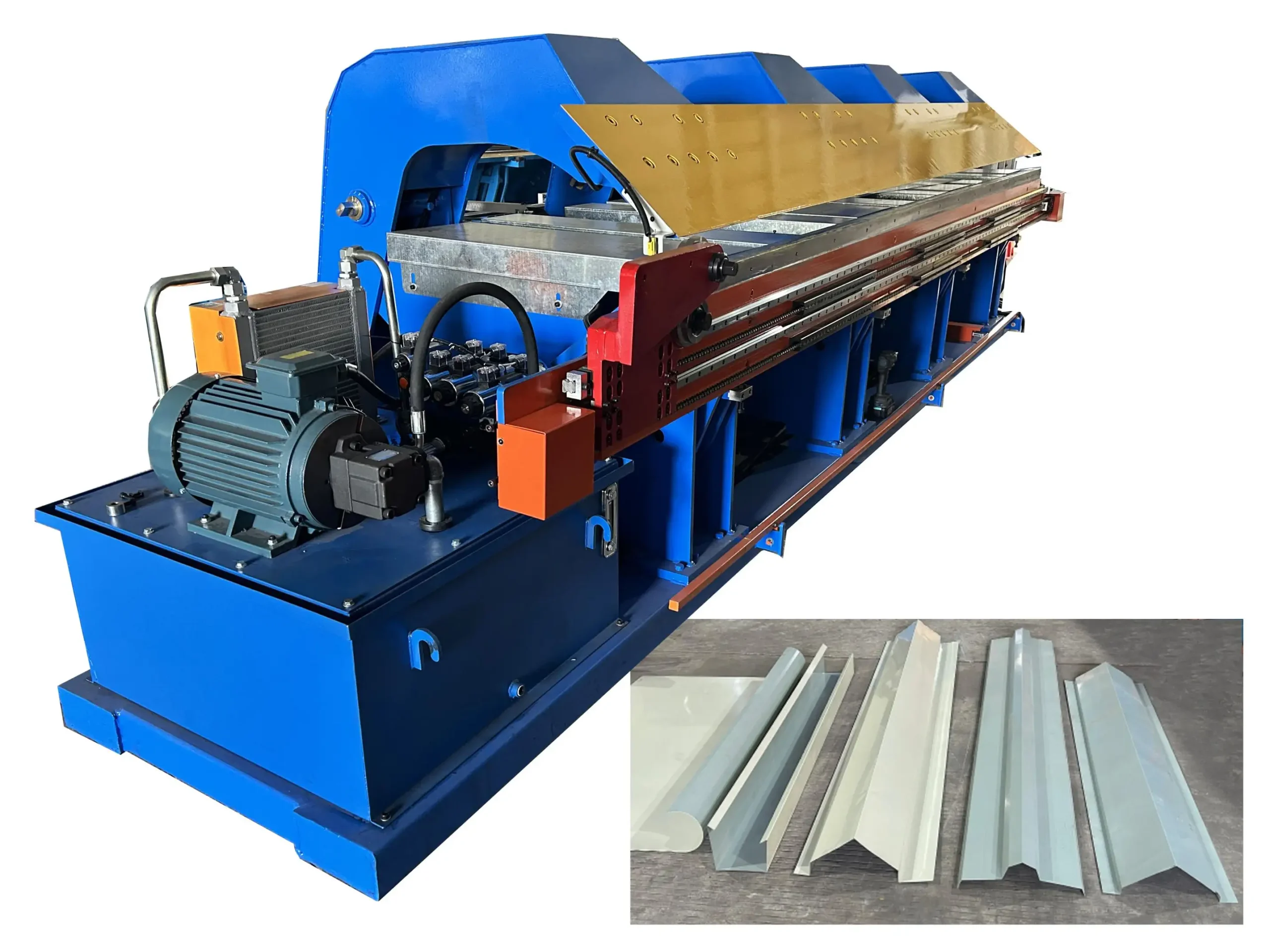

The C75-200 multi-specification light steel frame machine is an efficient equipment designed for manufacturing heavier and wider cross-section light steel frames and trusses. The production range of the machine covers 75mm to 200mm and is subdivided into four areas: 75-96mm, 96-117mm, 117-138mm, and 138-200mm. During the production process, only the stamping dies of chamfer cutting 2 and notch cutting 2 need to be replaced to easily realize the production and processing of materials of different widths, greatly improving production flexibility and efficiency.

The Multi Profiles Light Steel Frame Machine supports three different sizes of flanges (flanges), namely 32mm, 41mm and 51mm, to meet the needs of different application scenarios. This multi-specification design enables the equipment to be widely used in a variety of building structures, including walls, floors, and roofs of 1 to 5-story residential buildings, modular houses, movable units, light commercial buildings, and customized building projects such as solar panel frames.

Den vigtigste fordel ved dette udstyr er dets effektive produktionskapacitet og fleksible drift. Gennem enkel udskiftning af formen kan brugerne skifte til at producere lette stålkøl med forskellige specifikationer på kort tid og derved reducere nedetid og forbedre produktionseffektiviteten. Derudover anvender C75-200-maskinen et avanceret automatisk kontrolsystem for at sikre høj præcision og konsistens i produktionsprocessen, reducere menneskelige betjeningsfejl og forbedre produktkvaliteten.

I byggebranchen er C75-200-maskinen til formning af køl i let stål med flere specifikationer blevet det foretrukne udstyr for mange byggefirmaer og produktionsvirksomheder på grund af dens fremragende ydeevne og brede vifte af anvendelsesmuligheder. Uanset om det bruges til beboelsesejendomme, erhvervsbygninger eller specialprojekter, kan udstyret levere effektive og pålidelige løsninger, der hjælper brugerne med at opnå hurtig produktion af bygningskonstruktioner i høj kvalitet.

Tekniske parametre

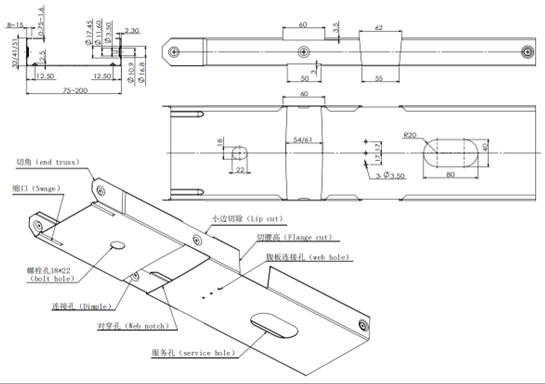

METRISKE STANDARDSTØRRELSER

| Sektionens størrelse | 75 mm | 89 mm | 92 mm | 102 mm | 140 mm | 200 mm |

| Webbredde | 75 mm | 89 mm | 92 mm | 102 mm | 140 mm | 200 mm |

| Flangehøjde | 32 til 51 mm | 32 til 51 mm | 32 til 51 mm | 32 til 51 mm | 32 til 51 mm | 32 til 51 mm |

| Servicehul *1 | 40*80mm | 40*80mm | 40*80mm | 40*80mm | 40*80mm | 40*80mm |

| Hul med fordybning *2 | 4,8 mm | 4,8 mm | 4,8 mm | 4,8 mm | 4,8 mm | 4,8 mm |

| Tykkelsesområde | 0,8-1,2 mm | 0,8-1,6 mm | 0,8-1,6 mm | 0,8-1,6 mm | 0,8-1,6 mm | 0,8-1,6 mm |

Detaljer om maskinen

1. The feeding guide device of the roll forming machine is a key equipment in the roll forming production line. It is mainly used to accurately and smoothly introduce raw materials (such as metal sheets, plastic films, etc.) into the roller system of the roll forming machine to ensure the continuity of the forming process and the quality of the product.

2. Stansesystem

The holes parameter is able to set by the computer, including Punching length and numbers.

Alle stanseforme er fremstillet af Cr12Mov

Driven by a hydraulic station

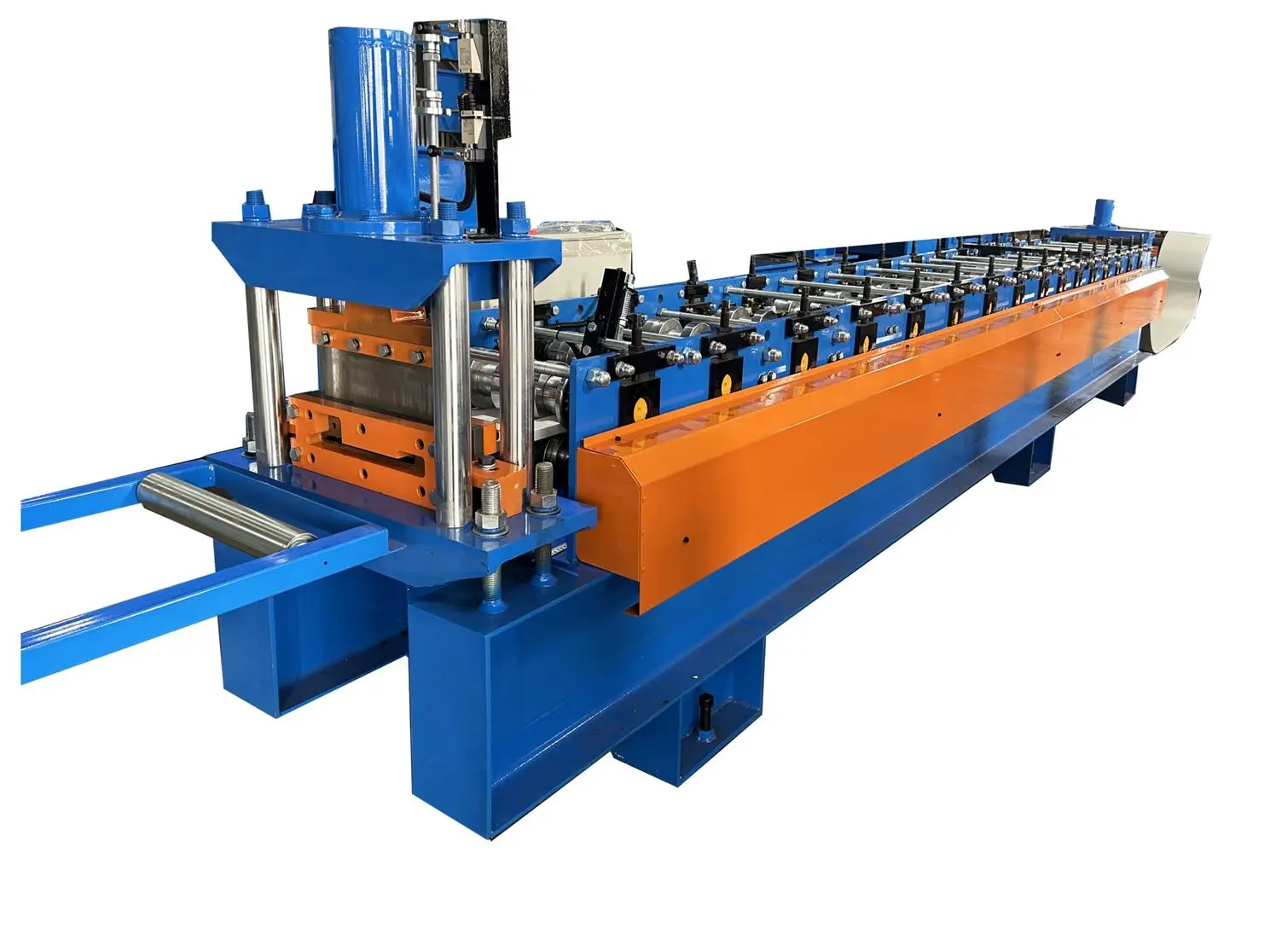

3. Hovedmaskine

Vægt af maskine: 10 tons

Størrelse på maskine: 8500*1550*1900mm

Servomotorens effekt: 14 KW

Formningshastighed: 35m/min

Comprehensive speed: 5-12m/min, depending on the number of holes, swagand cutting.

Rullestation: 17

Roller material: Cr12 mold steel, being quenched treatment, with digital-controlled processing. This ensures rollers are all in good condition and long life.

Materiale til skaft: 40Cr, CNC-bearbejdning

Transmissions- og fremføringsmetode: Styreaksel og styrehjul

Løbende video

Anvendelser

- Bygge- og anlægsbranchen: Ideel til fremstilling af stålrammer, der bruges i bolig-, erhvervs- og industribygninger.

- Infrastrukturprojekter: Velegnet til fremstilling af strukturelle komponenter i broer, lagerbygninger og modulære konstruktioner.

- Specialfremstilling: Muliggør præcis og skræddersyet bearbejdning af specialiserede stålprofiler.

- Batch-produktion: Håndterer effektivt fremstilling af standardiserede profiler i stor skala. Dette alsidige system giver innovative løsninger til flere byggeindustrier

- Konstruktioner i flere etager: load-bearing walls, composite floors, and pitched roof systems certified for 1-5 storey residential/commercial buildings

Fordele ved flere LGSF-maskiner

1. **Positioneringsteknologi med høj præcision**.

– The equipment adopts an advanced automatic positioning system, achieving millimeter-level precision during the processing, effectively avoiding positioning errors common in traditional manual operations. Its automatic positioning function not only ensures the accuracy of wall keel processing but also maximizes product consistency and integrity, providing reliable assurance for subsequent construction.

2. **Intelligent driftserfaring**.

Udstyret følger et humaniseret designkoncept og har en intelligent betjeningsgrænseflade med et enkelt tryk:

- Udstyret med en 21-tommers high-definition touchscreen med intuitive og klare instruktioner

- Kan gemme op til 100 sæt behandlingsparametre til hurtig genfinding og brug

- Overvågning af udstyrets status i realtid gennem automatisk registrering

Det reducerer de tekniske krav til operatørerne betydeligt og forbedrer arbejdseffektiviteten.

3. **Høj produktionskapacitet**.

Gennem procesoptimering og intelligent styring:

- Daglig produktion pr. maskine kan nå 6-8 tons

- Effektiviteten øges med 300% sammenlignet med traditionel manuel behandling

- Kvalificeringsgraden for det færdige produkt forbliver konstant over 99,5%

Forarbejdningscyklussen forkortes betydeligt, hvilket skaber større økonomiske fordele for virksomheden.

4. **Multiple sikkerhedsbeskyttelser**.

Udstyret er udstyret med et omfattende sikkerhedssystem:

- Automatisk overbelastningsbeskyttelse

- Sikkerhedsanordning til nødstop

- Dobbelt grænsebeskyttelse

- Nødafbrydelsessystem

Det sikrer operatørernes sikkerhed og en stabil drift af udstyret.