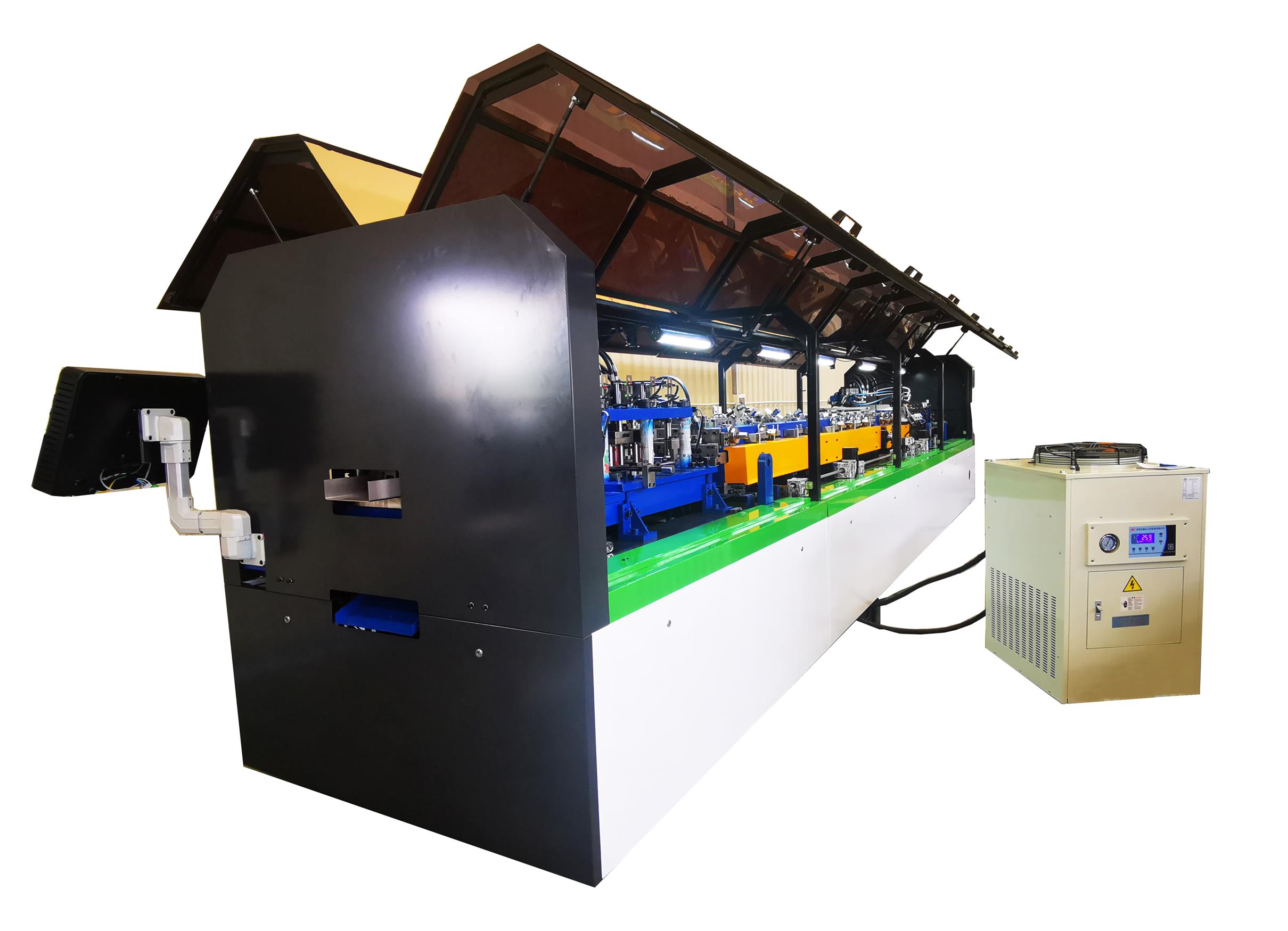

High-speed stud roll forming machine, as a popular equipment in the construction industry, is specially used to produce the support and installation studs required by the construction industry with its efficient production capacity and precise forming technology to meet the needs of various construction projects.

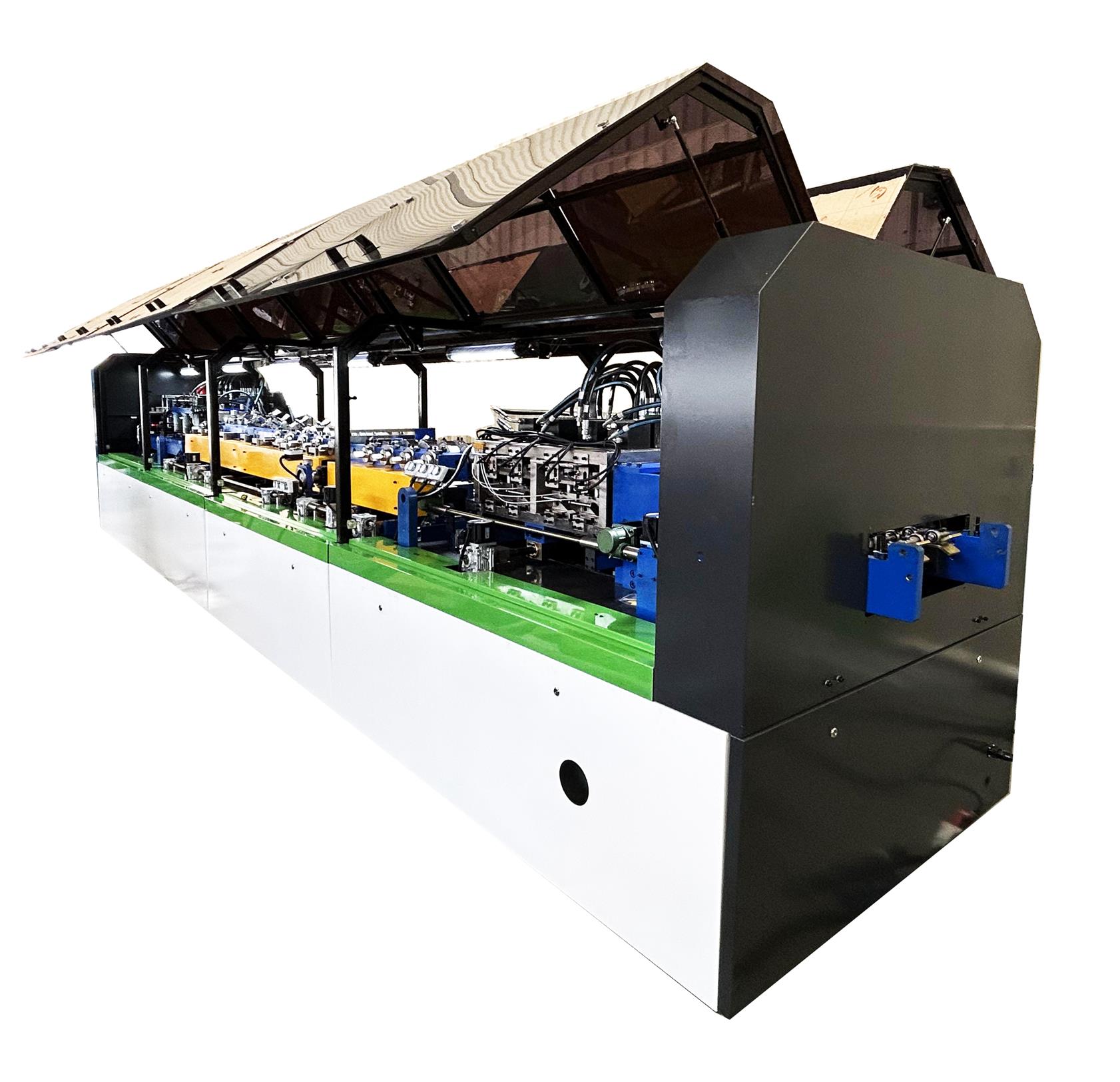

Parámetros de la perfiladora en U

- Adecuado para materiales con un grosor de 1,2-2,5 mm

- El eje es de 45# y está mecanizado con precisión

- Accionamiento por motor, transmisión por cadena de engranajes, 16 rodillos para conformar.

- Regulación de la velocidad de conversión de frecuencia. La velocidad de conformado es de unos 18 m/min.

- Sistema de control PLC (pantalla táctil marca: Alemán Schneider Electric / Taiwán WEINVIEW,

- Marca del inversor: Taiwán DELTA, marca del codificador: Japón Koyo/Omron)

- Basta con ajustar la WEB, la ALTURA y el LIP deseados con ayuda del reloj de posición que lleva (con pantalla digital, fácil de manejar) con el volante,

- A continuación, introduzca los datos de producción necesarios en la pantalla táctil.

- Todas las operaciones pueden realizarse en sólo 5-10 minutos. No es necesario cambiar rodillos, juntas ni cortadores como en las máquinas tradicionales anticuadas (cada cambio de tamaño de producción lleva más de 45 minutos).

- Combinado con: PLC, inversor, pantalla táctil, codificador, etc.

- Tolerancia de la longitud de corte ≤±2 mm

- Tensión de control 24V

- Manual de instrucciones en inglés

The U-profile shaping machine’s primary characteristics are as follows:

- High flexibility: By simply adjusting and creating U-shaped purlins of various diameters without requiring the replacement of gaskets or rollers, the machine significantly increases production efficiency.

- Tool versatility: To accommodate U-profiles of various sizes, there is no need to constantly switch out tools, saving time and money on tool replacement while maintaining processing precision and consistency.

- Simple and easy to use: The design minimizes operator skill requirements, cuts down on training time and expense, and is straightforward to use.

- Low maintenance costs: The equipment’s sturdy construction and ease of maintenance cut down on maintenance expenses while extending the equipment’s useful life.

- Size customization: U-profiles of any size may be created to satisfy various technical requirements within the machine’s size range, therefore conserving resources and cutting manufacturing costs.

- Punching function: It can punch holes on the web side of the purlin and the flange side of the U-profile at any location, which is very convenient for later assembly and installation.

Profiles and flow chart of U profile roll forming machine

Key Components of Stud and Track Machines

U-Slot Roll Forming Machine Straightening Section:

The straightening section is used to ensure that the raw material is in a straight state before entering the forming area, which helps to ensure the accuracy and quality of the final product.

U-Slot Roll Forming Machine Roller:

The roller is the core component of the forming machine, which is used to press the raw material into a predetermined U-shaped shape.

The roller is made of high-quality bearing steel GCr15 material, processed by CNC lathe and heat treated to ensure the hardness and wear resistance of the roller.

The roller surface can be optionally black treated or hard chrome coated, which further improves its service life and wear resistance.

Equipped with a feed guide to ensure that the raw material can enter the roller accurately and smoothly for forming.

The body frame is welded from 400# H-beam, which ensures the overall stability and durability of the machine.

Forming knife:

The forming knife is another key component in the forming process, which is used to accurately cut and form studs or tracks.

These knives are precisely designed to ensure that the studs and tracks produced are accurate in size and smooth in surface.

PLC control system (2 types available):

The PLC control system is the “brain” of the machine, responsible for controlling the entire forming process.

Users can easily set parameters, monitor operating status, and realize automated production through the control panel.

The system provides two optional configurations to meet the needs and budgets of different users.

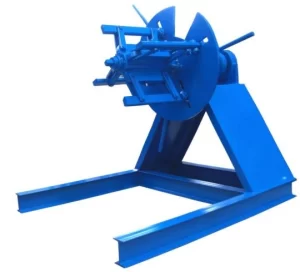

Uncoiler (2 types available):

The uncoiler is used to unwind the raw material coil and feed it into the forming machine.

The manual uncoiler is suitable for small-scale production or occasions where manual operation is required. Users can control the unwinding speed and tension of the coil through manual operation.

The hydraulic uncoiler is suitable for large-scale, automated production needs. It has a higher degree of automation and more stable unwinding performance, which can ensure the smooth unwinding and precise control of the coil.