Több LGSF gép jellemzői

- Feldolgozási képességek széles skálája

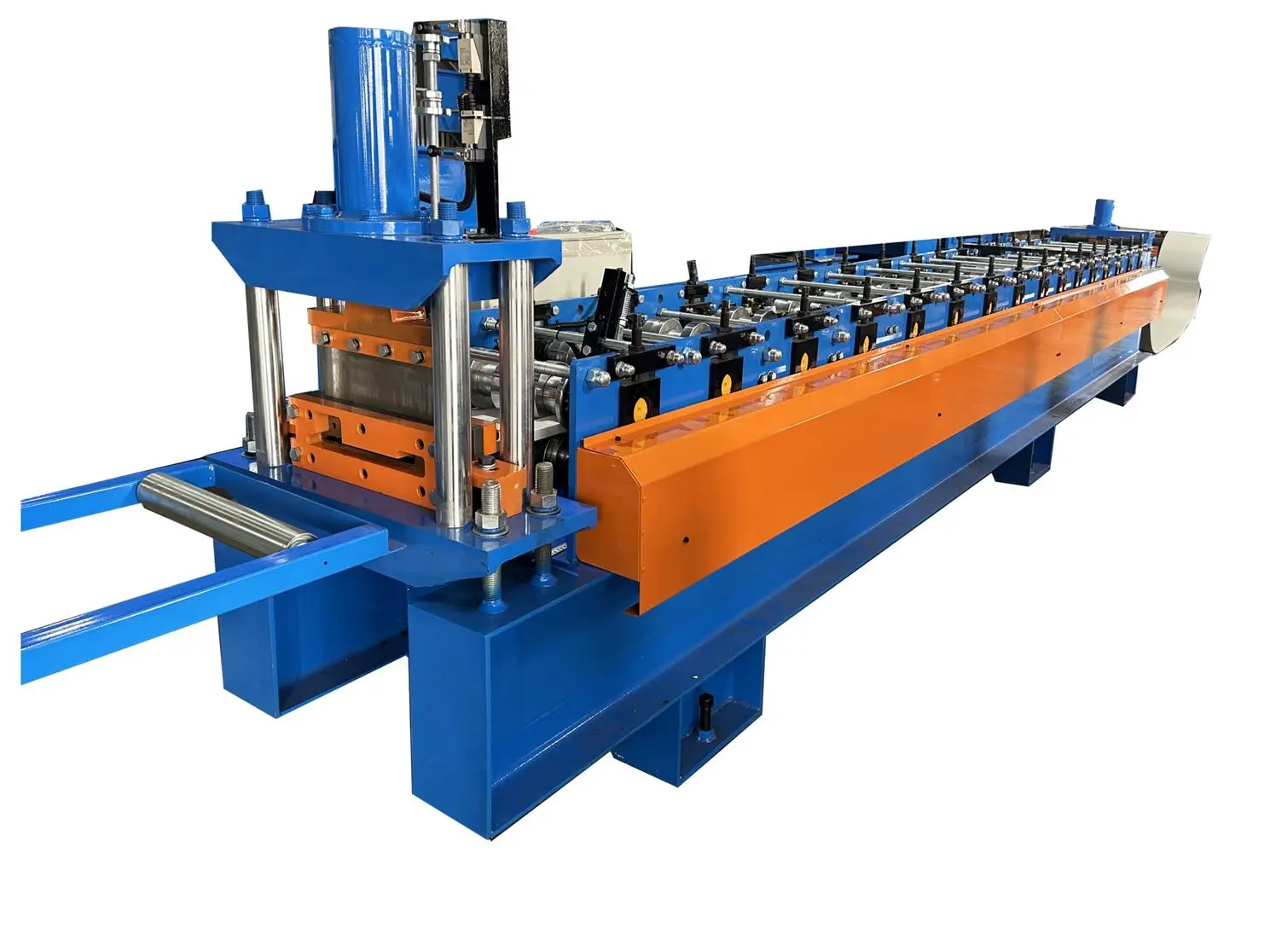

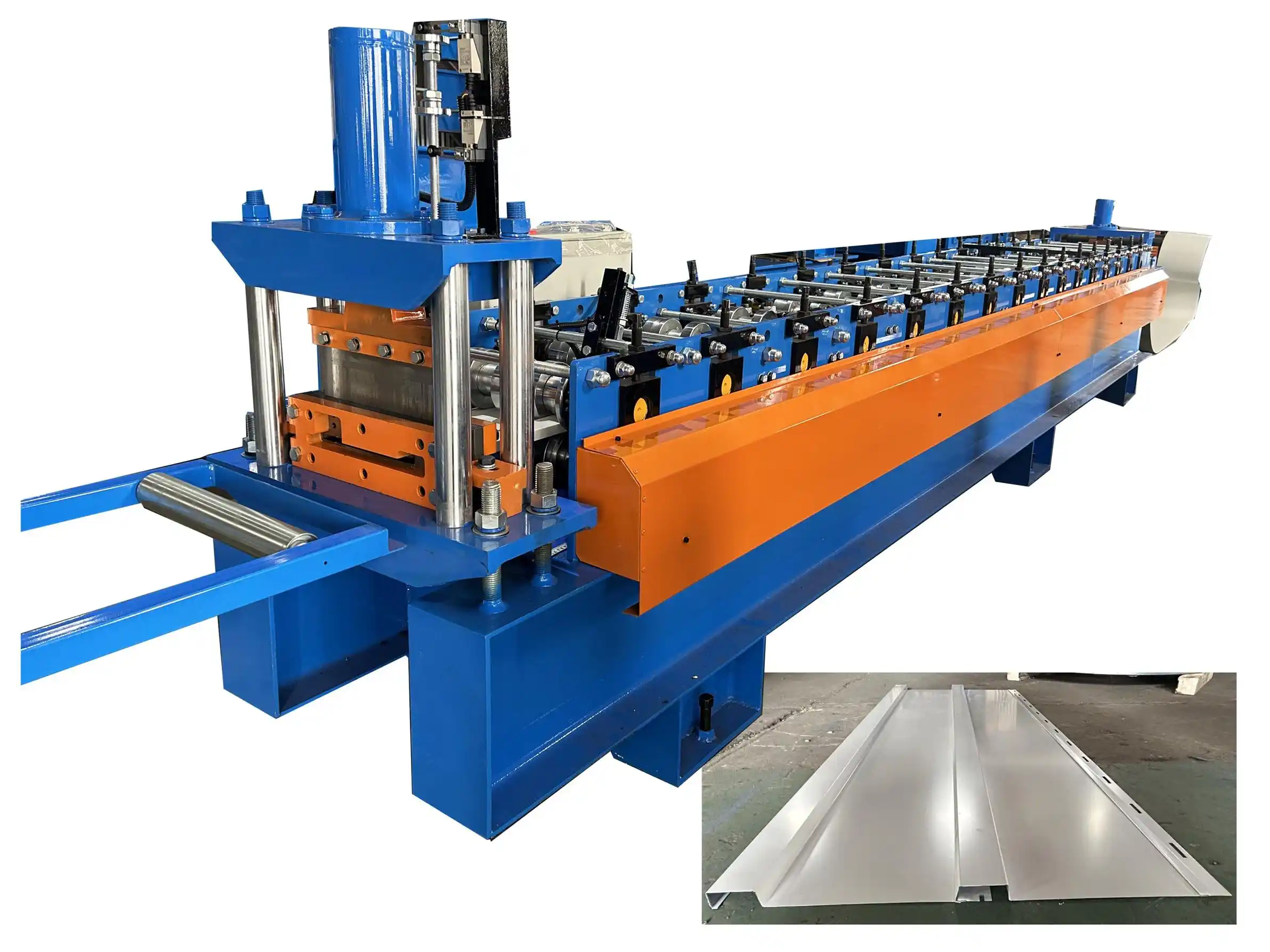

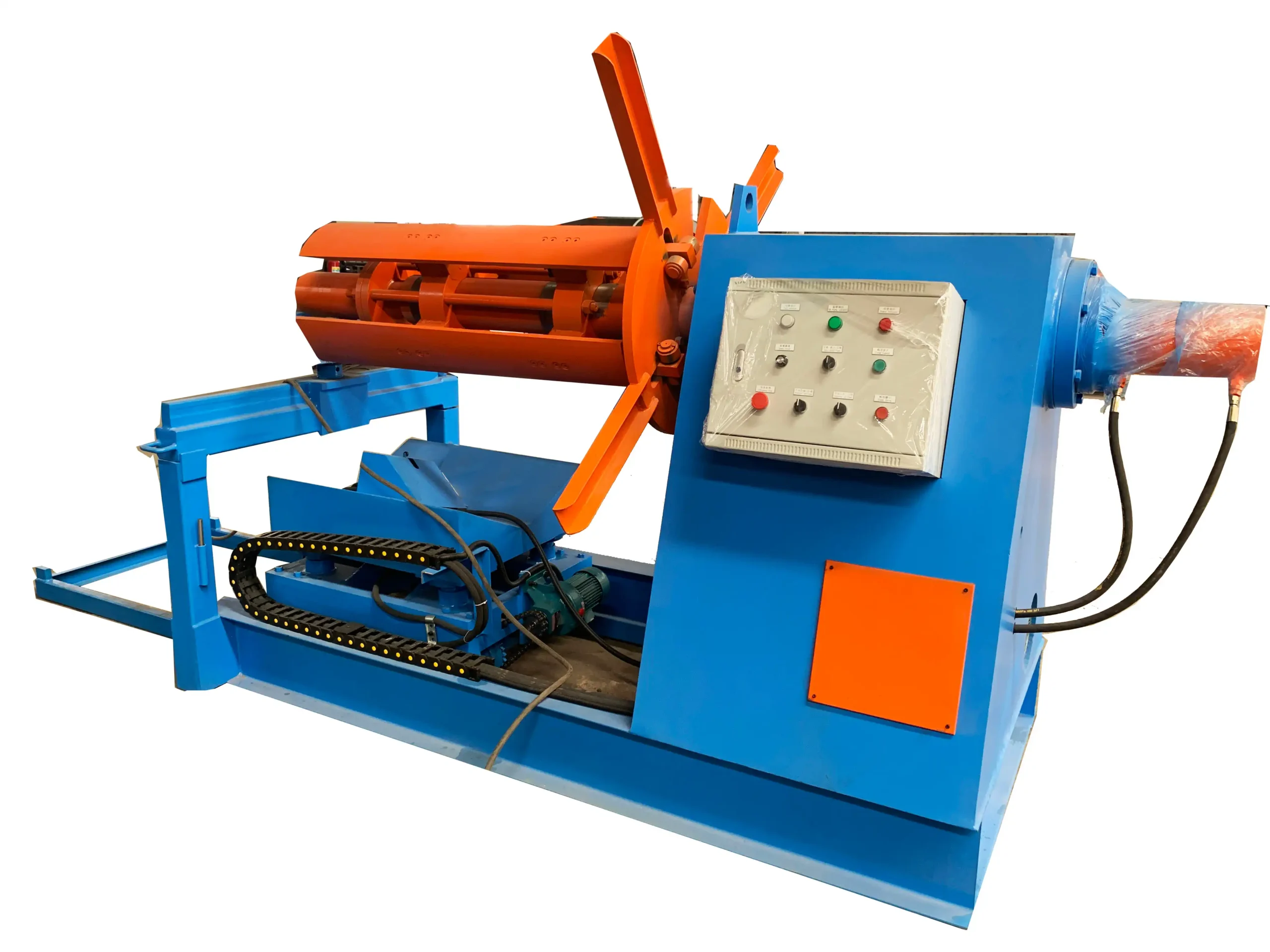

A C75-200 többféle acélvázas gép különböző acélprofilok befogadására alkalmas, így különféle ipari alkalmazásokhoz használható. A 75 mm-től 200 mm-ig terjedő profilok kezelésére való képessége biztosítja, hogy a felhasználók a gyártási igények széles skáláját elégíthetik ki anélkül, hogy több gépre lenne szükségük. - Kényelmes lyukasztószerszám-váltási funkció

A gép kiemelkedő jellemzője a gyorsan kapcsolható lyukasztó szerszámrendszer. A felhasználók könnyen cserélhetik a lyukasztószerszámokat a különböző termelési igényekhez igazodva, jelentősen csökkentve az állásidőt és növelve az általános termelékenységet. Ez a funkció lehetővé teszi a gyártási paraméterek gyors beállítását, így a gép nagy pontossággal és következetességgel képes különböző átmérőjű acélprofilok gyártására. - Nagy termelési hatékonyság

A C75-200 gép fejlett kialakítása biztosítja a nagy sebességű feldolgozást a kiváló minőség fenntartása mellett. Az áramvonalas működés és az automatizált funkciók minimalizálják a kézi beavatkozást, ami tovább növeli a termelés hatékonyságát. - Kivételes stabilitás és tartósság

A robusztus anyagokból és precíziós tervezéssel készült C75-200-as, több könnyű acélvázas gép kiemelkedő stabilitást és tartósságot kínál. Úgy tervezték, hogy ellenálljon a folyamatos üzemelés viszontagságainak, biztosítva a hosszú távú megbízhatóságot és a következetes teljesítményt. - Sokoldalúság a termelésben

Akár a kisüzemi egyedi gyártás vagy nagyüzemi kötegelt feldolgozása C75-200 gép képes a legkülönbözőbb vevői igények kielégítésére. Alkalmazkodóképessége ideális választássá teszi a precizitást és méretezhetőséget egyaránt igénylő gyártók számára. - Felhasználóbarát működés

A gép intuitív vezérlőrendszerrel van felszerelve, amely megkönnyíti a kezelők számára a gyártási folyamatok beállítását és kezelését. Ergonomikus kialakítása és felhasználóbarát kezelőfelülete csökkenti a betanulási időt és növeli a működési hatékonyságot. - Egységes feldolgozási minőség

A C75-200-as többszörös könnyű acélvázas gép minden profil esetében egységes feldolgozási minőséget biztosít. A precíz tervezés és a fejlett vezérlőrendszerek garantálják, hogy minden egyes acélprofil megfelel a legmagasabb ipari szabványoknak.

Műszaki paraméterek

| Modell | C75-200 |

| Web méret | 75-200mm |

| Profil magassága | 41mm |

| Profil Lip | 10-15mm |

| Szalag szélessége | 165-346mm |

| Anyagvastagság | 0.75-1.6mm |

| Mérőműszer beállítása | Teljesen automatikus szervo meghajtású |

| Tekercsformázó állomások | 17 |

| Átfogó gyártási sebesség | 8-15m/min |

| Gyártási sebesség (lyukasztás és vágás nélkül) | 35m/min |

| Tipikus termelési teljesítmény a gipszkarton panelhez | 600m/h |

| Tipikus termelési teljesítmény a tetőgerendák és a padlógerendák esetében | 480m/h |

| Gyártási sebesség (lyukasztás és vágás nélkül) | 2100m/h |

| Szervomotor (márka: Inovance) | 14kw |

| Hidraulikus rendszer(Brand: Japán YUKEN) | 11kw |

| PLC (márka: Japan Panasonic) | Panasonic |

| Teljesítmény feszültség | 380V/50Hz / 3 fázis (igény szerint konfigurálható) |

| Hidraulikus hűtés | Igen |

| Gép mérete (mm) | 8300x1600x1960 |

| Nettó súly | 10T |

| Jet nyomtató | Standard |

| Tervező szoftver | Vertex BD |

| De-coiler kapacitás | 3T, Powered |

| Lyukasztási/vágási pontosság | ±1mm/0.75mm |

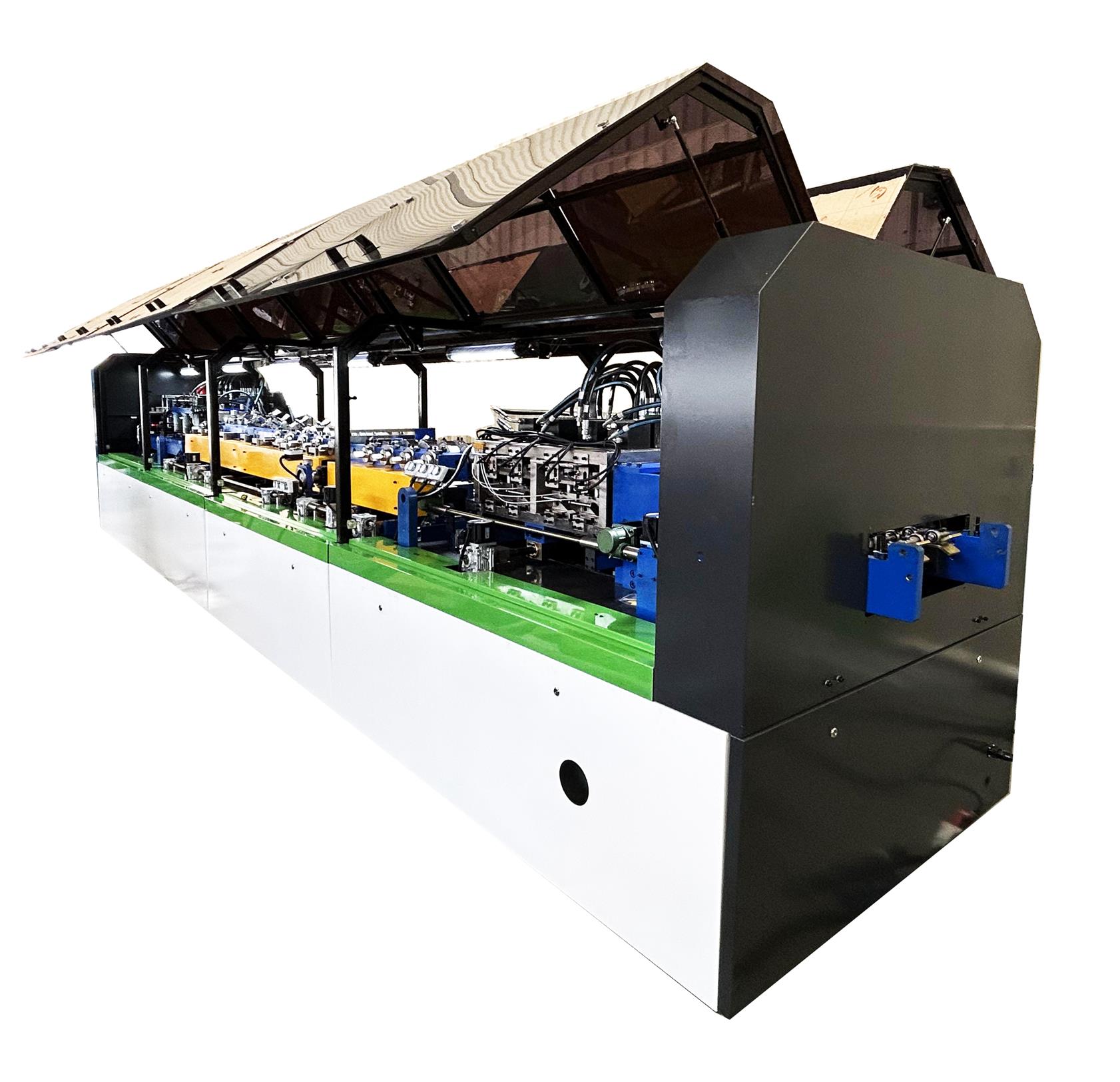

A gép részletei

Futó videó

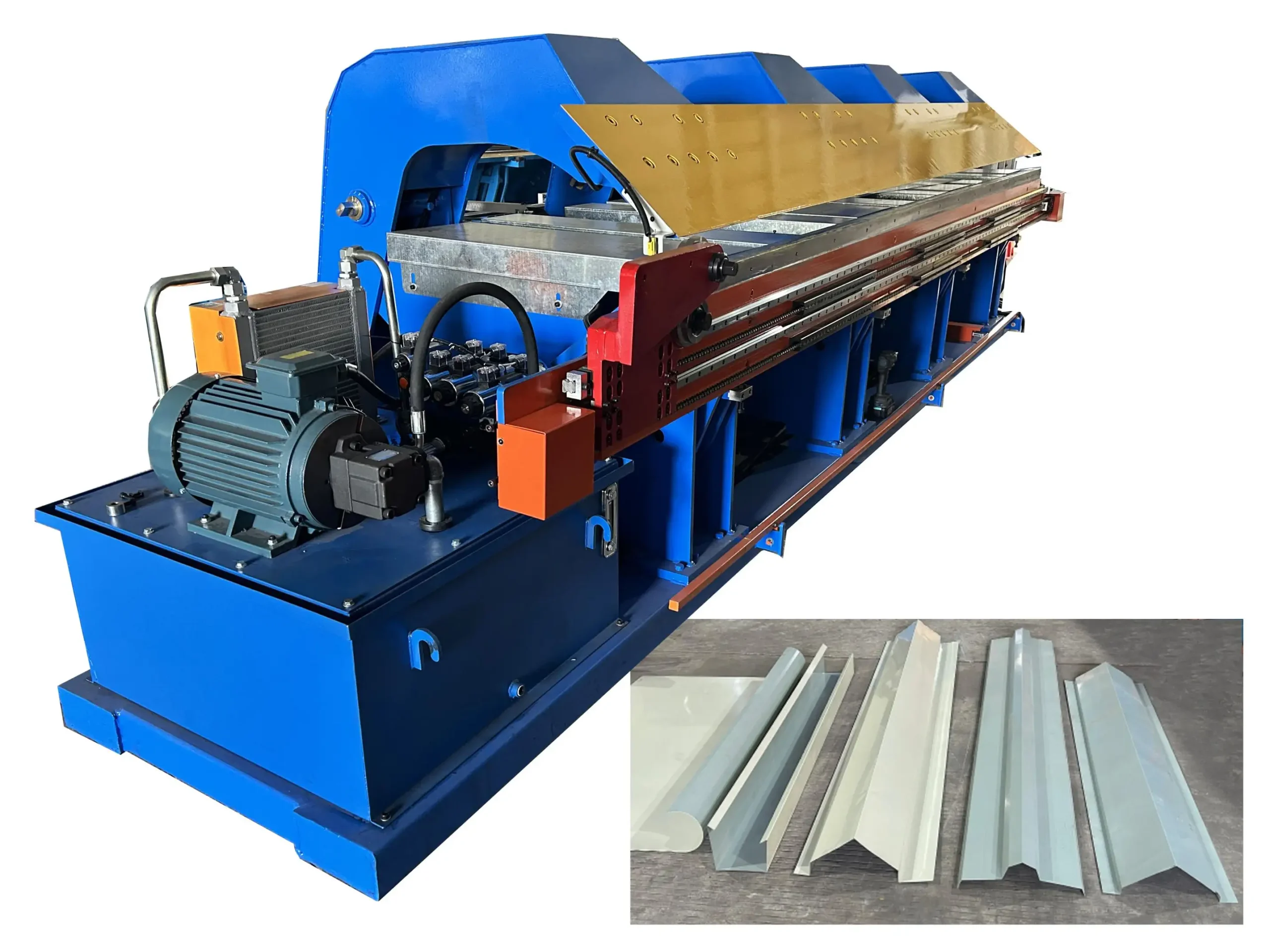

Alkalmazások

A több LGSF gép előnyei

1. Precíziós pozícionálási technológia. Ez a berendezés egy fejlett automatikus pozicionáló rendszert alkalmaz, amely milliméteres pontosságú pozicionálást képes elérni a feldolgozási folyamat során, hatékonyan elkerülve a hagyományos kézi működtetés pozicionálási hibáját. Automatikus pozicionáló funkciója nemcsak a falikibel feldolgozásának pontosságát biztosítja, hanem a termék konzisztenciáját és integritását is a legnagyobb mértékben garantálja, megbízható garanciát nyújtva a későbbi építéshez.

2. Intelligens működési tapasztalat. A humanizált tervezési koncepciót követve a berendezés egygombos intelligens kezelőfelületet alkalmaz:

A 21 hüvelykes, nagy felbontású érintőképernyővel felszerelt kezelési utasítások intuitívak és egyértelműek.

Akár 100 feldolgozási paraméterkészletet is tárolhat a gyors visszakeresés és használat érdekében.

Az automatikus észlelési funkció valós időben képes a berendezés működési állapotának nyomon követésére, ami hatékonyan csökkenti a kezelőkre vonatkozó műszaki követelményeket és jelentősen javítja a munka hatékonyságát.

3. Hatékony termelési kapacitás a gyártási folyamatok optimalizálásával és intelligens vezérléssel:

Egyetlen gép napi teljesítménye elérheti a 6-8 tonnát.

A hagyományos kézi feldolgozáshoz képest a hatékonyság 300%-rel nő

A késztermékek minősített aránya stabilan több mint 99,5% A feldolgozási ciklus jelentősen lerövidül, ami nagyobb gazdasági előnyöket teremt a vállalkozás számára.

4. Többszörös biztonsági védelem. A berendezés teljes körű biztonsági védelmi rendszerrel van felszerelve:

Automatikus túlterhelésvédelmi funkció

Vészleállító biztonsági berendezés

Kettős határérték-védelem

Vészhelyzeti kikapcsoló rendszer: Átfogóan biztosítja a kezelők biztonságát és a berendezés stabil működését.

GYIK

1. K: Ön gyártó?

V: Igen, szívesen látjuk Önt gyárunkban egy látogatásra. Gyárunk Xiamenben található, amely egy nemzetközi kikötő. A repülőtérről és a vasútállomásról a gyárunkba csak fél óra alatt juthat el, és autóval gondoskodunk a felszállásról.

2. K: Ön gyártó?

V: Igen, szívesen látjuk Önt gyárunkban egy látogatásra. Gyárunk Xiamenben található, amely egy nemzetközi kikötő. A repülőtérről és a vasútállomásról a gyárunkba csak fél óra alatt juthat el, és autóval gondoskodunk a felszállásról.

3. K: Elfogadnak-e az önök gyárai egyedi gépeket?

V: Igen, gyárunknak van egy professzionális tervezőcsapata, meg tudjuk tervezni a gépet az ügyfél igényei szerint

4. K: Mennyi a gyártási és szállítási idő?

V: A részletek megerősítése után körülbelül 1-3 hónap.

5. K: Mennyi a gyártási és szállítási idő?

V: A részletek megerősítése után körülbelül 1-3 hónap.

6. K: A tengerentúlon is biztosítanak telepítést és képzést?

V: A tengerentúli géptelepítési és munkavállalói képzési szolgáltatások opcionálisak.

7. K: Melyek a fő termékei?

V: Könnyű acél keretező gép, nagynyomású PU habosító vonal, purlin gép, tetőpanel gép, cserép tetőpanel gép, hullámos gép, padlóburkolat gép, és így tovább.