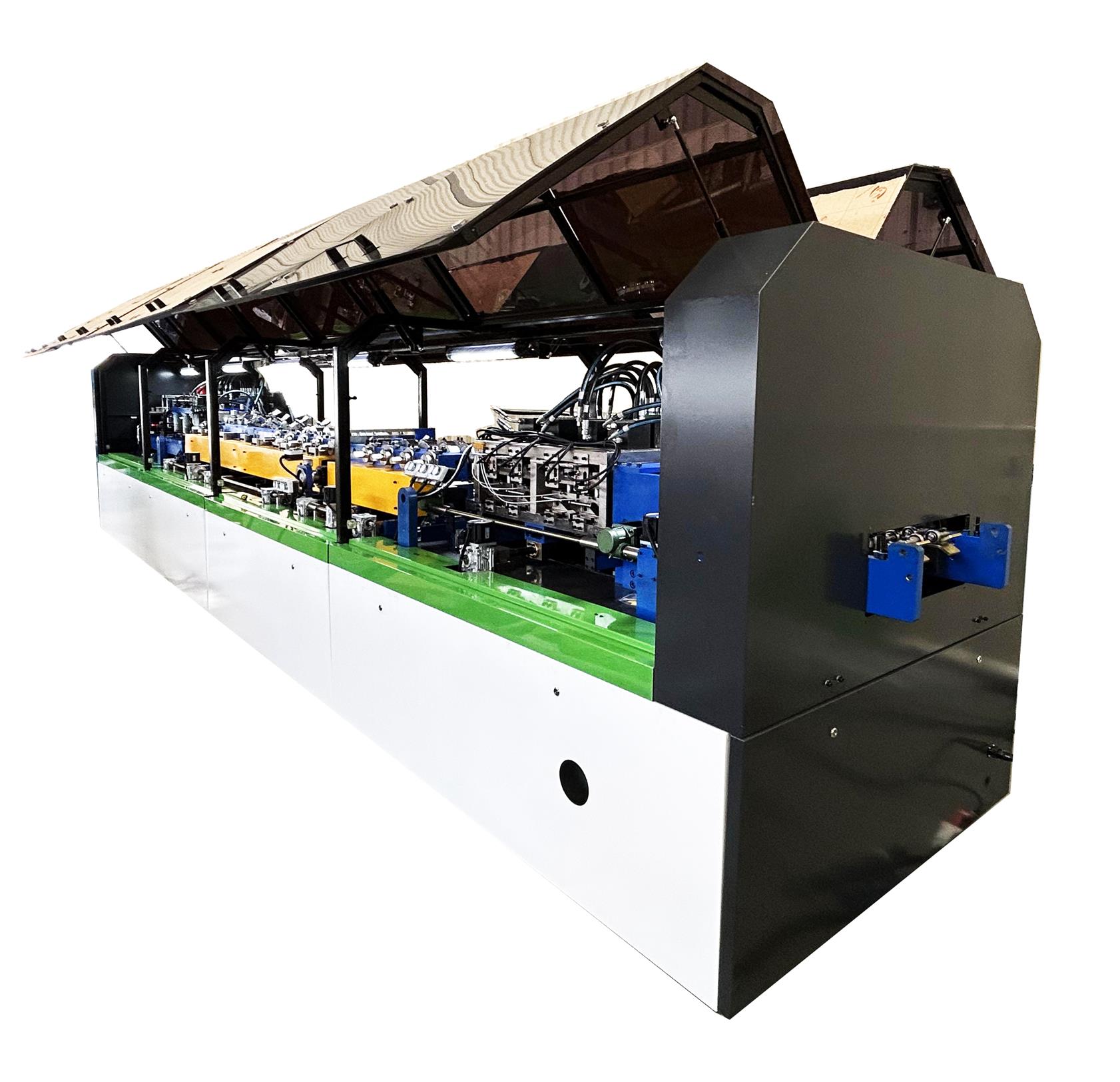

Caratteristiche multiple della macchina LGSF

- Ampia gamma di capacità di lavorazione

La macchina per telai in acciaio C75-200 può ospitare una varietà di profili in acciaio, rendendola adatta a diverse applicazioni industriali. La capacità di gestire profili da 75 mm a 200 mm consente agli utenti di soddisfare un'ampia gamma di requisiti di produzione senza dover ricorrere a più macchine. - Comoda funzione di commutazione dell'utensile di punzonatura

Una caratteristica distintiva di questa macchina è il suo sistema di utensili di punzonatura a cambio rapido. Gli utenti possono cambiare facilmente gli utensili di punzonatura per adattarsi alle diverse esigenze di produzione, riducendo significativamente i tempi di inattività e migliorando la produttività complessiva. Questa funzionalità permette di regolare rapidamente i parametri di produzione, consentendo alla macchina di produrre profili in acciaio di vari diametri con elevata precisione e costanza. - Alta efficienza produttiva

Il design avanzato della macchina C75-200 garantisce una lavorazione ad alta velocità, pur mantenendo una qualità superiore. Il funzionamento snello e le funzioni automatizzate riducono al minimo l'intervento manuale, aumentando ulteriormente l'efficienza della produzione. - Stabilità e durata eccezionali

Costruita con materiali robusti e ingegneria di precisione, la macchina C75-200 con telaio in acciaio multi-leggero offre stabilità e durata eccezionali. È progettata per resistere ai rigori del funzionamento continuo, garantendo affidabilità a lungo termine e prestazioni costanti. - Versatilità nella produzione

Sia per produzione personalizzata su piccola scala o elaborazione in batch su larga scalaLa macchina C75-200 è in grado di soddisfare le diverse esigenze dei clienti. La sua adattabilità la rende una scelta ideale per i produttori che richiedono precisione e scalabilità nelle loro operazioni. - Funzionamento facile da usare

La macchina è dotata di un sistema di controllo intuitivo, che facilita agli operatori l'impostazione e la gestione dei processi produttivi. Il design ergonomico e l'interfaccia user-friendly riducono la curva di apprendimento e migliorano l'efficienza operativa. - Qualità di lavorazione costante

La macchina per telai in acciaio C75-200 assicura una qualità di lavorazione uniforme per tutti i profili. La sua precisa progettazione e gli avanzati sistemi di controllo garantiscono che ogni profilo in acciaio soddisfi i più elevati standard industriali.

Parametri tecnici

| Modello | C75-200 |

| Dimensione web | 75-200 mm |

| Altezza del profilo | 41 mm |

| Profilo Labbro | 10-15 mm |

| Larghezza della striscia | 165-346 mm |

| Spessore del materiale | 0,75-1,6 mm |

| Regolazione del manometro | Servoassistenza completamente automatica |

| Stazioni di laminazione | 17 |

| Velocità di produzione completa | 8-15 m/min |

| Velocità di produzione (senza punzonatura e taglio) | 35m/min |

| Produzione tipica per pannelli a secco | 600m/h |

| Produzione tipica per capriate per tetti e travetti per pavimenti | 480m/h |

| Velocità di produzione (senza punzonatura e taglio) | 2100m/h |

| Servomotore (marca: Inovance) | 14kw |

| Sistema idraulico (marca: Giappone) YUKEN (marchio) | 11kw |

| PLC (Marchio: Japan Panasonic) | Panasonic |

| Tensione di alimentazione | 380V/50Hz/3Fase (può essere configurato come richiesto) |

| Raffreddamento idraulico | Sì |

| Dimensione della macchina (mm) | 8300x1600x1960 |

| Peso netto | 10T |

| Stampante a getto | Standard |

| Software di progettazione | Vertex BD |

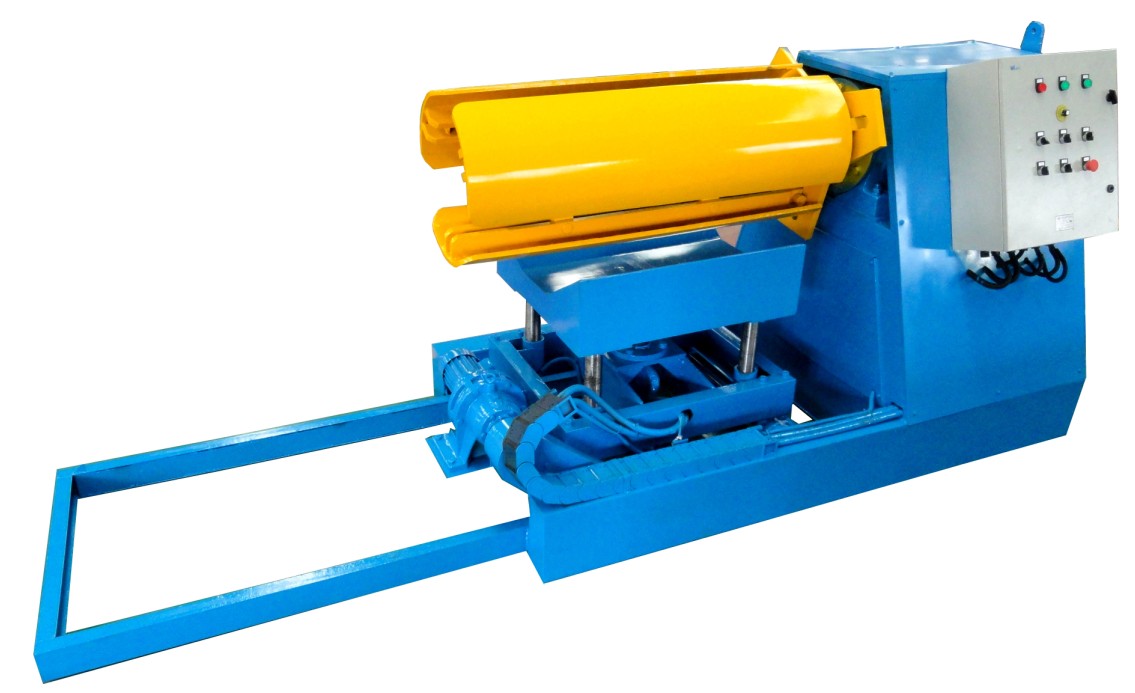

| Capacità del de-coiler | 3T, alimentato |

| Precisione di punzonatura/taglio | ±1mm/0,75mm |

Dettagli macchina

Video in esecuzione

Applicazioni

Vantaggi della macchina LGSF multipla

1. Precision positioning technology. This equipment adopts an advanced automatic positioning system, which can achieve millimeter-level precision positioning during the processing process, effectively avoiding the positioning error in traditional manual operation. Its automatic positioning function not only ensures the accuracy of wall keel processing, but also guarantees the consistency and integrity of the product to the greatest extent, providing a reliable guarantee for subsequent construction.

2. Intelligent operation experience. Adhering to the humanized design concept, the equipment adopts a one-button intelligent operation interface:

Dotato di un touch screen ad alta definizione da 21 pollici, le istruzioni per l'uso sono intuitive e chiare.

Può memorizzare fino a 100 set di parametri di elaborazione per un rapido recupero e utilizzo

The automatic detection function can monitor the operating status of the equipment in real time, effectively reducing the technical requirements for operators and greatly improving work efficiency.

3. Efficient production capacity through optimization of production processes and intelligent control:

La produzione giornaliera di una singola macchina può raggiungere le 6-8 tonnellate.

Rispetto all'elaborazione manuale tradizionale, l'efficienza è aumentata del 300%

Il tasso di qualificazione dei prodotti finiti è stabile a oltre il 99,5% Il ciclo di lavorazione è significativamente ridotto, creando maggiori vantaggi economici per l'impresa.

4. Multiple safety protections. The equipment is equipped with a full range of safety protection systems:

Funzione di protezione automatica da sovraccarico

Dispositivo di sicurezza per l'arresto di emergenza

Protezione a doppio limite

Emergency power-off system: Comprehensively ensure the safety of operators and the stable operation of equipment

FAQ

1. Q: Are you a manufacturer?

A: Yes, warmly welcome you to our factory for a visit. Our factory is located in Xiamen, which is an international port. From the airport and train station to our factory takes only half an hour, and we will arrange a car for pick up.

2. Q: Are you a manufacturer?

A: Yes, warmly welcome you to our factory for a visit. Our factory is located in Xiamen, which is an international port. From the airport and train station to our factory takes only half an hour, and we will arrange a car for pick up.

3. Q: Do your factories accept customized machines?

A: Yes, our factory has a professional design team, we can design the machine according customer’s requirements

4. Q: What are your manufacturing and shipping times?

A: About 1-3months after confirming the details.

5. Q: What are your manufacturing and shipping times?

A: About 1-3months after confirming the details.

6. Q: Do you provide installation and training overseas?

A: Overseas machine installation and worker training services are optional.

7. Q: What are your main products?

A: Light steel framing machine, high-pressure PU foaming line, purlin machine, roof panel machine, tile roof panel machine, corrugated machine, floor decking machine, and so on.