Jadro priemyselnej výroby

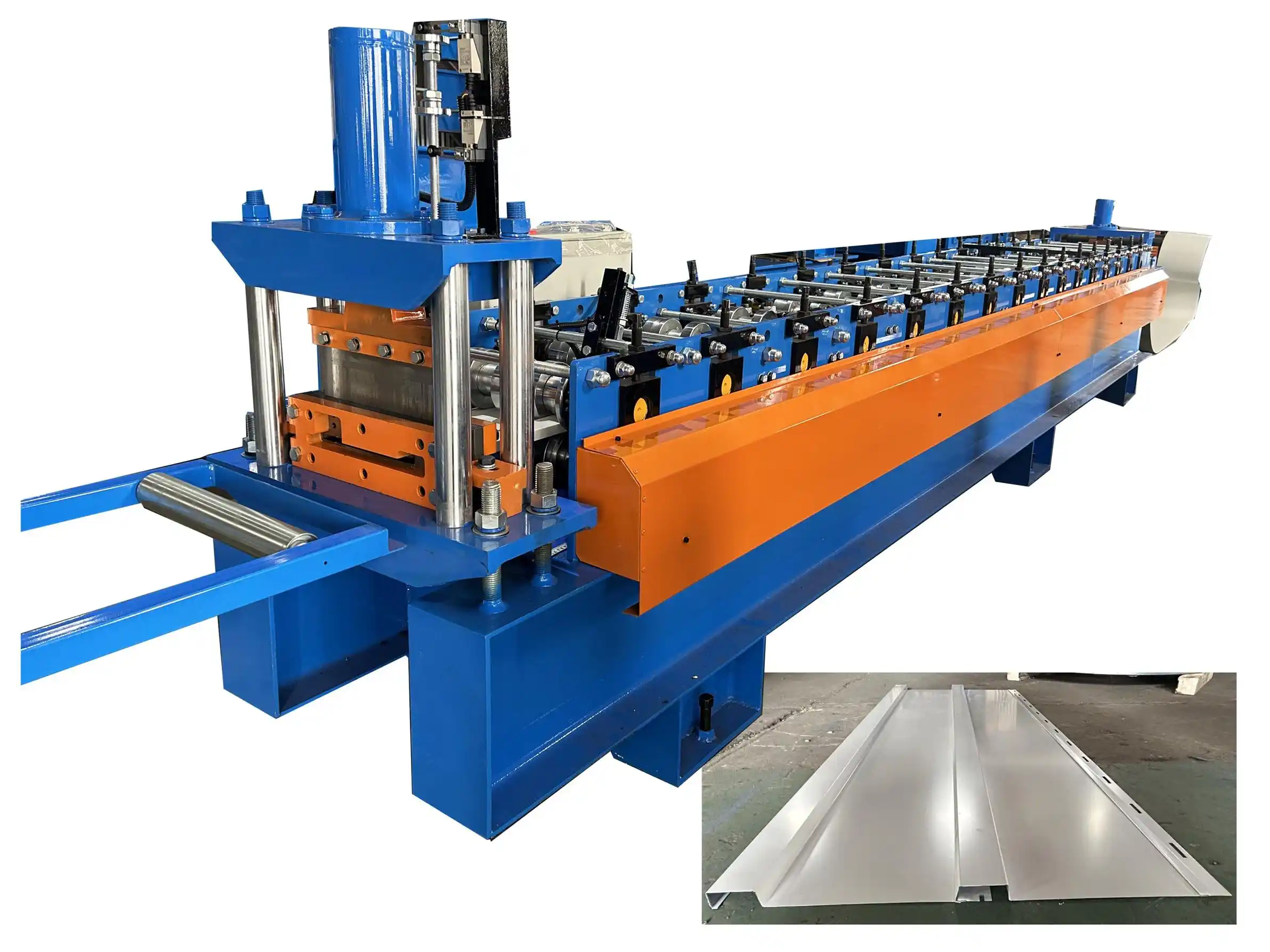

V jemnom systéme modernej priemyselnej výroby sa Nožný pedálový tvárniaci stroj funguje ako tichá, ale schopná "priemyselná základňa", ktorá s presnosťou strojovej pomoci zvyšuje produktivitu v mnohých oblastiach. Keď lešenie rastie ako oceľové drevo na stavbách, jeho hlavná časť - lešenárska doska - sa vždy vyrába týmto nástrojom rýchlosťou 12 metrov za minútu. Na linkách na výrobu automobilov pochádzajú správne krivky vnútorných podpier a pedálov z mnohých valcov jeho valčekového náradia. Tento nástroj, spájajúci pracovné miesta "strih-forma-dierovanie", svojou užitočnosťou podobnou "švajčiarskemu armádnemu nožu" mení spôsob výroby tovaru v starých časoch a je dôležitý medzi surovinami a hotovým priemyselným tovarom.

Ako sa štruktúra spája s funkciou

Umenie inžinierstva v mechanickom dizajne

- Hlavné teleso zariadenia je zvarené z vysokopevnostnej uhlíkovej ocele Q345B; hrúbka telesa je 20 mm a vydrží valivý tlak viac ako 30 ton. Rámová konštrukcia využíva konštrukciu mechanického vyváženia; stĺpy a nosníky sú vystužené trojuholníkovými podperami, aby sa zabezpečilo, že amplitúda počas vysokorýchlostnej prevádzky je ≤0,08 mm. Ovládací panel má ergonomické usporiadanie; tlačidlá núdzového zastavenia, gombíky na nastavenie parametrov a LED displej pracovného stavu sú umiestnené v tvare vejára, čo umožňuje obsluhe dokončiť celý proces v rozsahu 0,5 metra.

- Magnetická prášková brzda môže niesť cievky s priemerom 1,2 metra a hmotnosťou 5 ton. Prostredníctvom snímača napätia v reálnom čase upravuje rýchlosť odvíjania, aby sa zabránilo vráskam na plechoch spôsobeným náhlymi zmenami napätia.

Sedem valčekov má usporiadanie horný - tri - dolný - štyri. Ložisková oceľ GCr15, kalenie valčekov s tvrdosťou HRC60-62, schopná presného vyrovnania oceľových plechov s hrúbkou 0,5-4 mm; kontrola rovinnosti v rozsahu 0,2 mm/m; - Dierovacia jednotka CNC má 20 20-tonových hydraulických dierovacích lisov s rýchlosťou dierovania 30-krát za minútu a presnosťou polohy diery ±0,3 mm. Podporuje prepínanie viac ako 20 typov otvorov, ktorými sú okrúhle otvory, dlhé otvory a otvory v tvare pásu.

Analýza základných funkcií: Modernizácia efektívnosti na základe technológií

- Presné ovládanie systému servopohonu

Využíva servomotor Panasonic MINAS A6 s 2000-riadkovým snímačom, ktorý dosahuje presnosť podávania ±0,05 mm. Keď sa zistí kolísanie hrúbky materiálu väčšie ako 0,1 mm, podáva späť prostredníctvom snímača tlaku a automaticky upravuje rýchlosť podávania (nastaviteľná rýchlosť 0-25 m/min). Príklad: Výroba pozinkovaných plechov s hrúbkou 2 mm; chyba tradičného mechanického podávania je približne ±1 mm. Servosystém kontroluje chybu v rozmedzí ±0,3 mm, čím vytvára základ pre následné valcovanie. - Tajomstvo procesu kontinuálneho valcovania

Tvarovacia jednotka má 12 súprav lisovacích nástrojov, prvých 6 súprav sú hrubé tvarovacie valce a posledných 6 súprav sú jemné tvarovacie valce. Vezmime si ako príklad spracovanie drážky v tvare U lešenárskych dosiek: 1. - 3. sada valcov dokončí 90° predohyb s 5° kompenzáciou; 4. - 6. sada valcov vykoná korekciu oblúka na kontrolu chyby hĺbky drážky v rozmedzí ±0,5 mm; 7. - 12. sada valcov dokončí povrch tak, aby drsnosť Ra ≤ 1,6 μm. Celý proces je riadený programom PLC, ktorý dokáže uložiť parametre tvárnenia päťdesiatich rôznych výrobkov a čas prepínania ≤ 10 minút. - Prelomová technológia inteligentného rezania

Prelom v inteligentnej technológii rezania: hydraulicky poháňané lietajúce strihacie zariadenie dosahuje rýchlosť rezania 80-krát za minútu a dokáže bez otrepov rezať oceľové plechy s hrúbkou pod 4 mm. Systém podporuje dva režimy: rezanie s pevnou dĺžkou (0,5 - 6 m) a rezanie s počítaním metrov. Vďaka polohovaniu pomocou fotoelektrického snímača je chyba dĺžky ≤±1mm; účinnosť sa v porovnaní s tradičným ručným značením a rezaním zvyšuje 8-krát.

Tri hlavné výhody, ktoré nanovo definujú štandardy priemyselnej výroby

- Dvojnásobné zvýšenie výrobnej kapacity a efektívnosti

Denná výrobná kapacita jednej výrobnej linky dosahuje 12 000 metrov (počítané ako 2 m dlhé lešenárske dosky, 6 000 kusov denne), čo zodpovedá dennému pracovnému zaťaženiu 20 kvalifikovaných pracovníkov. Po zavedení tohto zariadenia v továrni na stavebné zariadenia sa cyklus dodávok lešenárskych dosiek skrátil zo 7 dní na 2 dni; rýchlosť reakcie na objednávky sa zvýšila o 71%. - Zabezpečenie kvality presnej výroby

Proces kontroly kvality certifikovaný podľa normy ISO9001 dokazuje, že zariadenie vyrobilo lešenárske dosky s pevnosťou v ťahu 345 MPa a medzou klzu 235 MPa, ktoré presahujú požiadavky normy GB/T 1591-2018. Výsledky skúšok soľnou hmlou (5% roztok NaCl, 240 hodín) dokazujú, že rýchlosť korózie pozinkovanej vrstvy je ≤0,1 mm/rok, čo je vhodné pre pobrežné stavebné projekty. - Možnosť flexibilného prispôsobenia

Podporuje rýchlu výmenu matrice (čas výmeny matrice ≤ 30 minút) a dokáže vyrábať viac ako 20 typov profilov, ako je oceľ v tvare C (100-300 mm), oceľ v tvare Z (120-250 mm) a drážky v tvare U (50-200 mm). Továreň na výrobu automobilových súčiastok použila toto zariadenie na prispôsobenie držiakov batérií z hliníkovej zliatiny pre nové modely energetických vozidiel, pričom dosiahla proces ohýbania pod uhlom 90° + obrubovanie prostredníctvom 16 súprav špeciálnych lisovacích nástrojov s výťažnosťou výrobku 99,2%.

Presná reakcia od požiadavky po implementáciu

- Premena požiadaviek na inžinierske riešenie

Technický tím premieňa požiadavky zákazníka na parametre riadenia procesu pomocou 3D modelovania SolidWorks. Napríklad fotovoltaický podnik požadoval, aby uhol ohybu nosného profilu bol 158°±1°. Technický personál vypočítal kompenzačný uhol lisovania na 162° pomocou simulácie procesu valcovania metódou konečných prvkov. Konečná chyba uhla výrobku bola ≤0,5°. - Reverzný dizajn lisovacích nástrojov

V prípade dielov špeciálneho tvaru sa údaje o vzorkách získavajú pomocou technológie 3D skenovania (presnosť ±0,02 mm) a spätný návrh výliskov sa vykonáva prostredníctvom softvéru UG. Nožné pedále leteckého podniku zo zliatiny titánu. Na vyriešenie problému tepelnej deformácie pri spracovaní titánovej zliatiny navrhol technický tím na základe údajov zo skenovania špeciálne lisovacie formy s chladiacimi drážkami. - Systém kontroly kvality celého procesu

Pri skúšobnej výrobe sa zavádza "systém troch kontrol" (prvá kontrola, obchôdzková kontrola a záverečná kontrola) pomocou súradnicového meracieho stroja (presnosť ±0,01 mm), kľúčové rozmery sú zistiteľné. V tomto projekte vysokorýchlostných železničných dielov sa 200 úpravami skúšobnej výroby nakoniec dosiahla priamosť profilu na úrovni 0,1 mm/m - požiadavka certifikácie CRCC.

Rôzne aplikačné scény: Technická adaptácia v rôznych odvetviach

Bezpečnostný základ stavebných projektov

Počas výstavby tretej vzletovej a pristávacej dráhy medzinárodného letiska v Hongkongu lešenárske dosky z tohto zariadenia podopierali 120-metrovú výškovú pracovnú plošinu. Hĺbka protišmykovej drážky dosiahla 0,8 mm; koeficient trenia bol 0,65, čo bolo bezpečné pre pracovníkov stavby počas tajfúnov. Dosky sú spojené skrutkami presným dierovaním; nosnosť spojov je až 2,5 tony, čo je viac, než vyžadujú britské normy BS 1139.

- Presný spojenec špičkovej výrobyAerospace: Výroba držiakov nožného ovládača pre lietadlo C919 s použitím materiálu z hliníkovej zliatiny 7075-T6, dosiahnutie tvaru s hrúbkou steny 0,3 mm prostredníctvom 10 súprav presných lisov, pričom pri kontrole chýb röntgenom neboli zistené žiadne chyby vnútorného otvoru;

- Zdravotnícke pomôcky: Výroba rámov dverí kabíny štítu pre CT prístroje s použitím techniky valcovania nehrdzavejúcej ocele, aby tesnosť zvaru dosiahla 1×10⁹Pa -m³/s, čo spĺňa pravidlá radiačnej bezpečnosti.

- Železničná doprava: Frekvencia vibrácií držiaka sa vyhýba rezonančnému rozsahu vozidla (18 - 22 Hz).

V oblasti vodíkovej energie je toto zariadenie schopné spracovať kovové bipolárne dosky pre zásobníky palivových článkov. Dosahuje to prostredníctvom valcovania 0,1 mm ultratenkých plechov z nehrdzavejúcej ocele, čím sa dosahuje presnosť veľkosti prietokového kanála ±0,03 mm, ale aj rovnomerné rozloženie vodíka a kyslíka.

Od stavania lešení až po vysoko presné diely pre lietadlá sa valcovací stroj s nožným pedálom stal hlavným spôsobom zlepšovania priemyslu vďaka svojim dvom veľkým výhodám "presná výroba + jednoduchá výroba". Na vlne inteligentnej výroby bude aj naďalej poskytovať úplné riešenia od "suroviny" po "finálny výrobok" pre mnohé oblasti prostredníctvom technologických zmien v oblasti inteligencie, ekologickosti a miešania, čím sa skutočne stane nenahraditeľným "pomocníkom všetkých remesiel" v modernej priemyselnej výrobe.