High Pressure Steel Belt Sandwich Panel Line Advantages

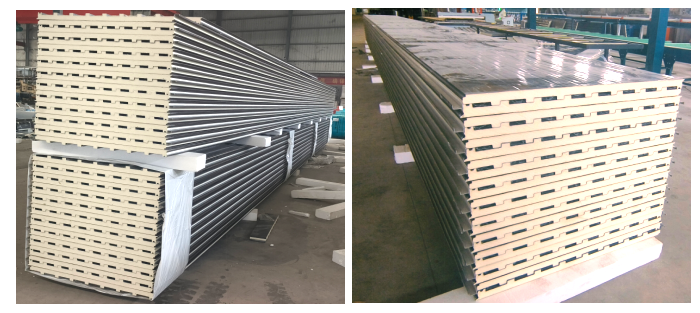

Modern construction demands materials that are **strong, lightweight, easy to install, reliable, and durable**. High-pressure rigid polyurethane (PU) foam meets all these requirements while offering **exceptional fire resistance and thermal insulation**, making it ideal for applications such as:

Cold storage & refrigeration

Hospitals & healthcare facilities

Automotive manufacturing

Stadiums & large-scale structures

Villas & high-end buildings

Our high-pressure PU production line** delivers superior performance, matching global industry standards with the following advantages:

**Key Benefits:**

1. **Fire Resistance** – Complies with **B2-grade fireproofing** standards.

2. **Thermal Insulation** – Achieves refrigeration/cold-storage-level efficiency.

3. **Superior Foam Quality** – High-pressure mixing ensures **homogeneous AB material distribution**, enhancing foam consistency and **extending service life**.

4. **Cost Efficiency** – **7–9% raw material savings** vs. low-pressure systems.

5. **Self-Cleaning System** – Nozzles require **no manual cleaning**, reducing maintenance effort.

6. **Automated Flying Saw Cutting** – Minimizes labor costs with precision cutting.

7. **Safety Assurance** – Patented **pressure detection protection** for stable, safe operation.

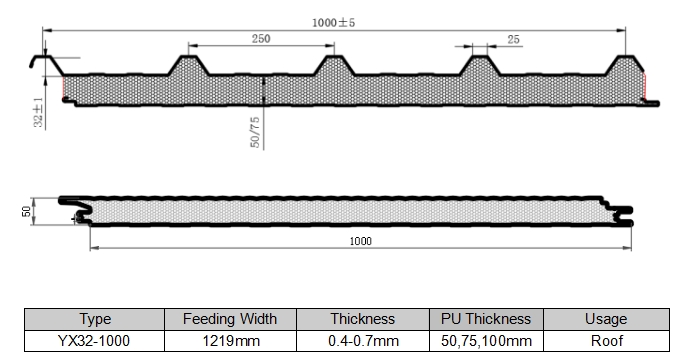

8. **Customizable Options** – Available with **dual-sided metal cladding** (thickness: **50mm, 70mm, 100mm**).

### **Why Choose Our PU Line?**

By integrating **advanced automation, material efficiency, and stringent safety controls**, our system optimizes productivity while ensuring long-term durability—making it the **preferred choice for high-performance insulation solutions worldwide**.

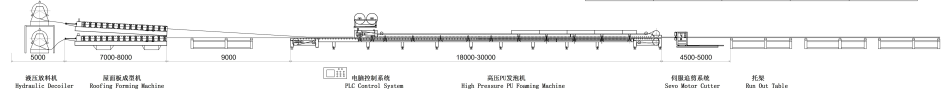

Flowdiagram

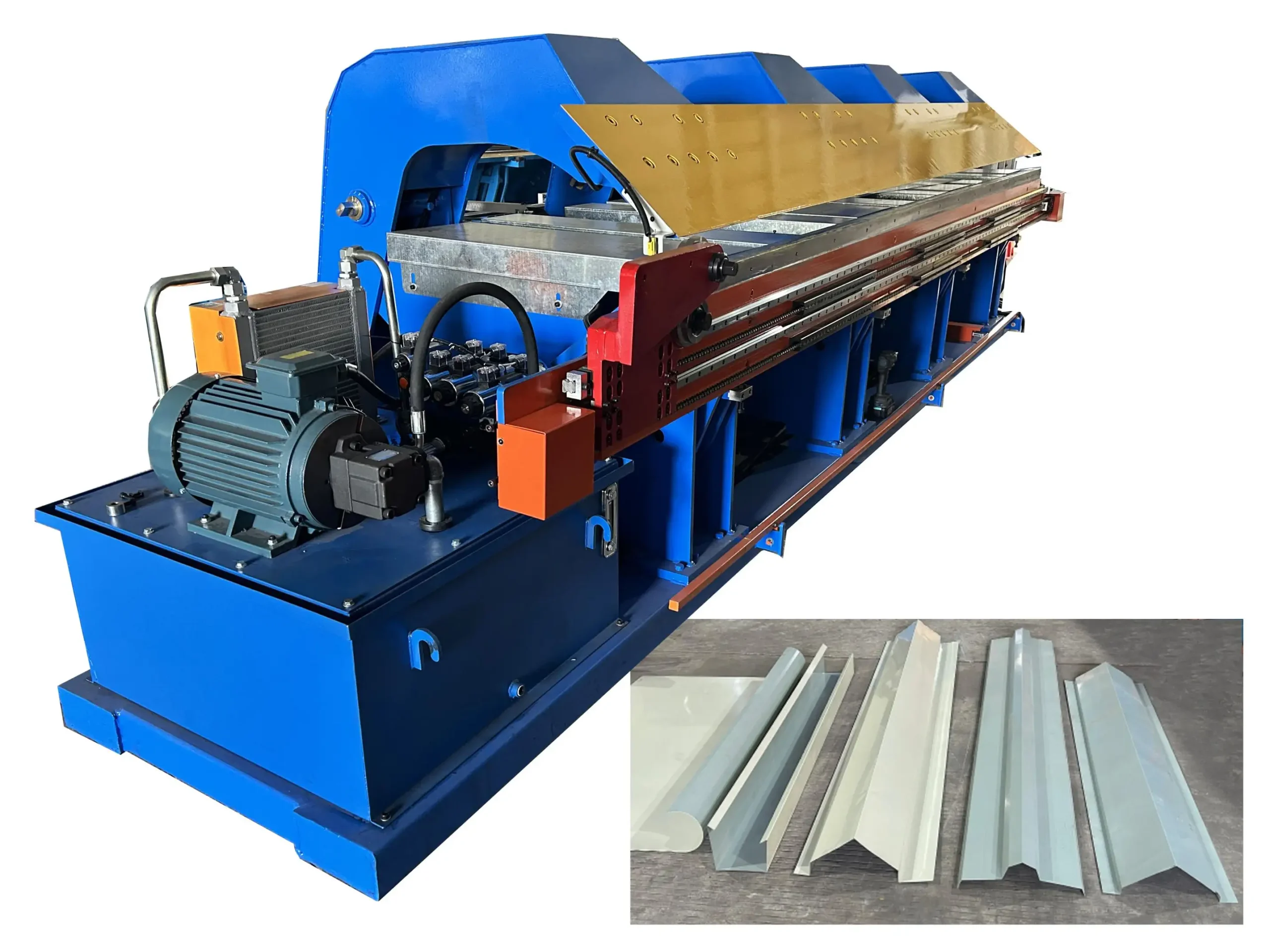

Populære profiler til tag og væg

Løbende video

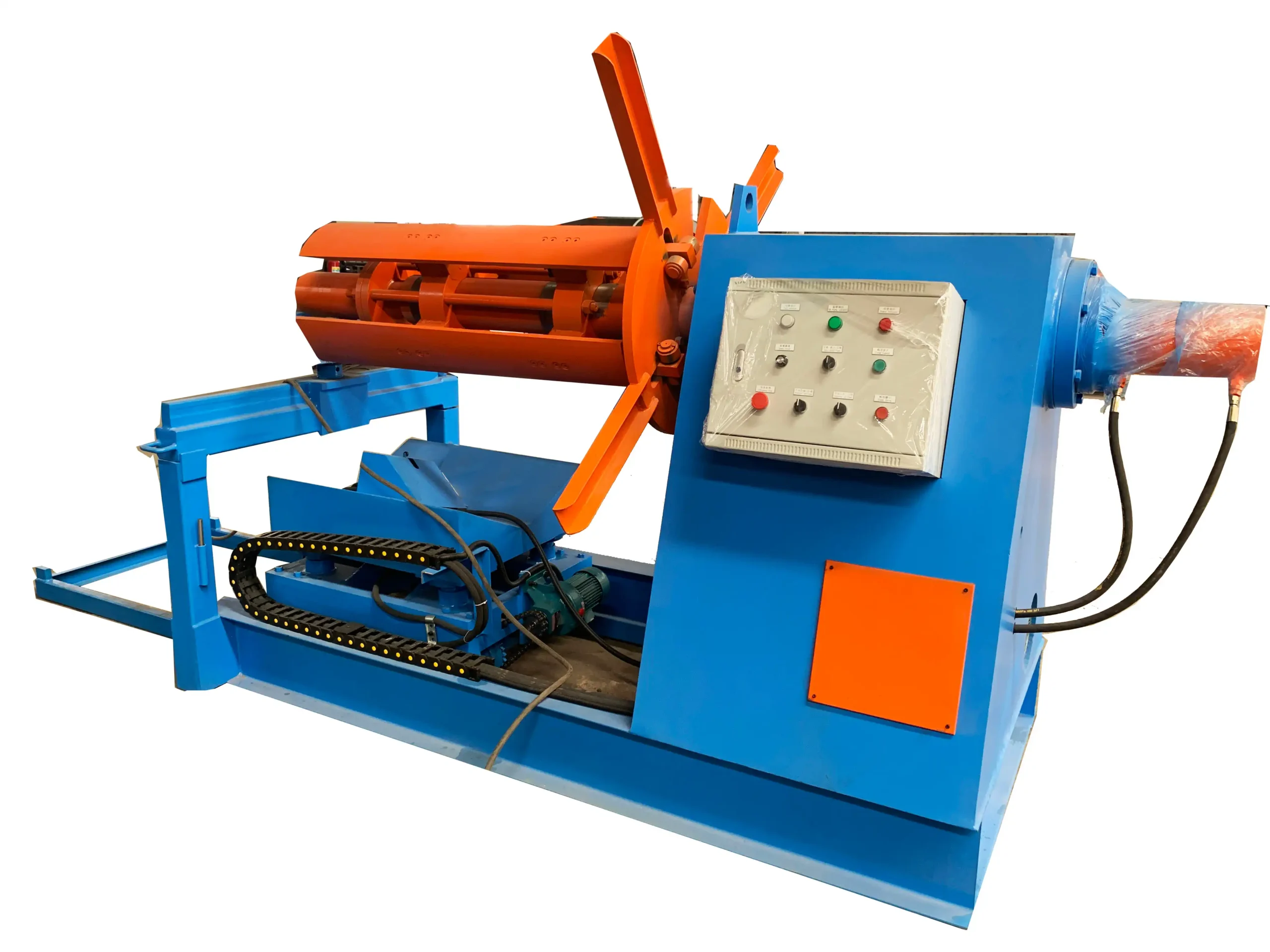

Komponenter til maskine til sandwichpaneler

2 sæt 5 tons hydrauliske afrullere med læssevogn

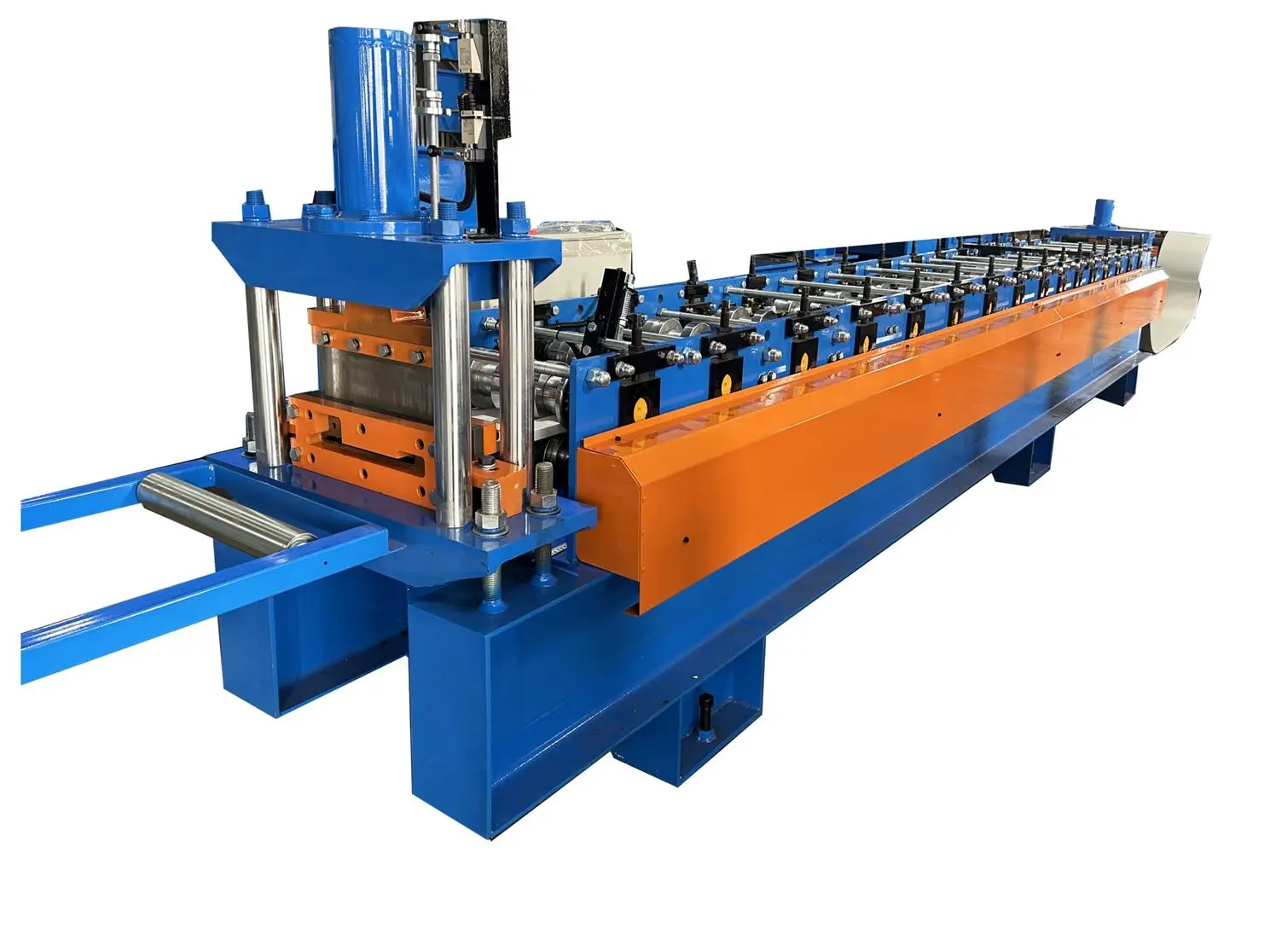

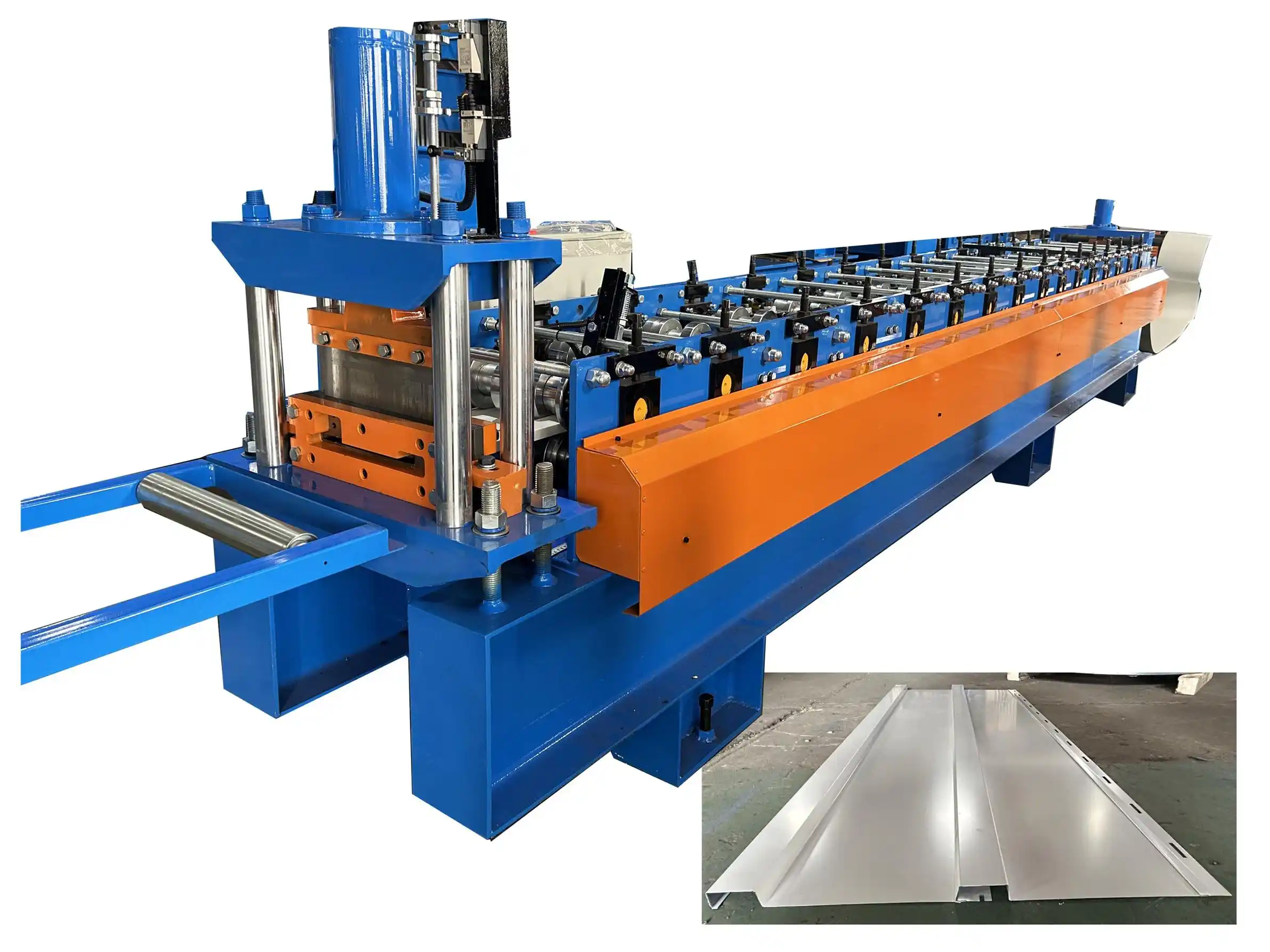

2 sæt rulleformningsmaskiner

Double Roll Forming Machine – Precision & Efficiency for Your Production Line

Among the core components of the production line, the double roll forming machine plays a critical role in ensuring synchronous, precise, and efficient material shaping. This advanced equipment processes raw materials into predefined dimensions and profiles using high-precision roll forming technology, meeting strict product specifications.

1 sæt højtryks PU-skumningssystem

**Principle and comparison of high-pressure foaming and low-pressure foaming of polyurethane**

1. Low-Pressure Foaming

Principle:

Mechanical mixing: Mix material A (isocyanate) and material B (polyol + additives) by low-speed stirring (200-1000 rpm), and inject them into the mold by gravity or low pressure.

Chemical reaction: Isocyanate (-NCO) reacts with polyol (-OH) to form polyurethane, accompanied by the formation of CO₂ bubbles (foaming agent effect).

Funktioner:

– The mixing accuracy is low, and problems such as uneven bubbles and inconsistent density are prone to occur.

2. High-Pressure Foaming

Principle:

High-pressure impact mixing: A and B materials are accurately measured under high pressure (100-200 bar) and instantly mixed (mixing time <1ms) by high-precision collision mixing heads.

-Atomization mixing: High pressure makes the raw materials atomized to ensure uniform mixing at the molecular level.

Core advantages of high-pressure foaming:

1. More uniform mixing and finer pores

– High-pressure atomization can reduce dead zones and avoid defects caused by unmixed materials (such as lumps and uneven bubbles).

2. Higher production efficiency

– Suitable for automated continuous production.

3. Less material waste

– The mixing head is self-cleaning, with a residual amount of <0.1%, which reduces raw material loss and can save 7-9% of raw materials compared to low-pressure foaming.

4. Better product performance

– The pore structure is more uniform.

High-pressure foaming technology is superior to low-pressure foaming in terms of mixing accuracy, production efficiency and product performance, and is particularly suitable for high-end manufacturing.

1 sæt pu-værtsmaskine

Længden på PU-hovedrammen er normalt 25 til 30 meter, hvilket bestemmes af tegningerne fra kunden og den krævede skumtykkelse. For bedre at kunne imødekomme kundernes produktionsbehov er udstyret designet under fuld hensyntagen til mangfoldigheden og fleksibiliteten i forskellige produktspecifikationer, så det kan tilpasses forskellige produktionsscenarier.

Vores mainframe anvender et transmissionssystem med gummibælter, som ikke kun sikrer udstyrets stabilitet og effektivitet under drift, men også reducerer maskinens produktionsomkostninger betydeligt. Sammenlignet med traditionelle transmissionsmetoder er gummibælter fremragende til stødabsorbering og slidstyrke, hvilket forlænger udstyrets levetid, reducerer vedligeholdelsesfrekvensen og sparer efterfølgende driftsomkostninger for virksomhederne.

1 Hele sættet af PLC-kontrolsystem

Hele hovedmaskinen består af 3 dele: rulleformningsmaskine, PU-skumningssystem og klippesystem. Hver del har et uafhængigt elektronisk kontrolsystem, og de 3 systemer kan betjenes intelligent online.

1 Flyvende skæresystem

Servo motor cutting system

1 Pneumatic Stacker

- Grab Length: 1.5-12m

- Grab Width: 930-1160mm

- Maximum Grab Weight: 500kg

- Automatic Flip

- Fully Automatic Computer Control

1 Wrapping Packaging Machine

- Packaging Dimensions: 1200 x 1000

- Product Weight: 2 tons

- Packaging Material: Stretch Film

- Stretch Film Dimensions: Width 500mm, Diameter within 250mm

- Stretch Film Core Inner Diameter: 75mm

- Packaging Method: Horizontal Conveyor Rotary Packaging

- Film Loading Method: Ring Drives Mold Rotation

- Conveyor and Ring Speeds Adjustable by Frequency Converter

- Roller Length: 10 meters for both front and rear ends of the wrapping machine

Anvendelser