Steel Floor Decking Machine Application

Metal floor decking machine (also known as metal floor decking forming machine) is a professional equipment used to produce corrugated steel plates for construction. Its products are widely used in modern building structures.

Actual application scenarios

1. Commercial and industrial buildings

• The preferred floor material for large-span spaces such as large shopping malls, logistics warehouses, and factory buildings, used to quickly build multi-story structures. For example: warehouse loft platform, data center mezzanine, etc.

2. Public facilities

• Floor slabs of subway stations and airport terminals are vibration-resistant and durable.

Advantage analysis

1. Structural performance optimization: Through the coordinated work of shear nails and concrete, the bending stiffness is increased by 30%-40%, and the deflection deformation is reduced.

2. Construction efficiency breakthrough

• The mechanized installation speed reaches 200㎡/man-day, which saves 70% of the construction period compared with traditional wooden formwork and reduces the use of scaffolding.

3. Economic comparison

• Reduce overall costs by 15%-25%:

• Material savings: Steel plate thickness can be optimized to 0.8mm (traditional 1.2mm);

• Later savings: Eliminate template removal and repair costs.

4. Sustainable development

• 100% recyclable steel, 85% less construction waste. Additional points for materials can be obtained in LEED certification projects.

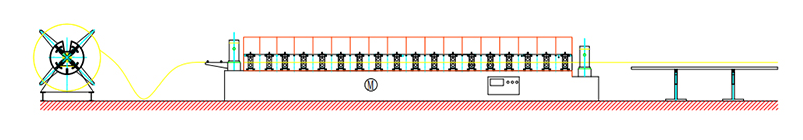

Flow Chart of Floor Decking Machine

Decoiler→Dispositivo di guida di alimentazione→Dispositivo di pretaglio (opzionale)→Sistema di profilatura→Dispositivo idraulico di taglio dei pali→Cremagliera di uscita

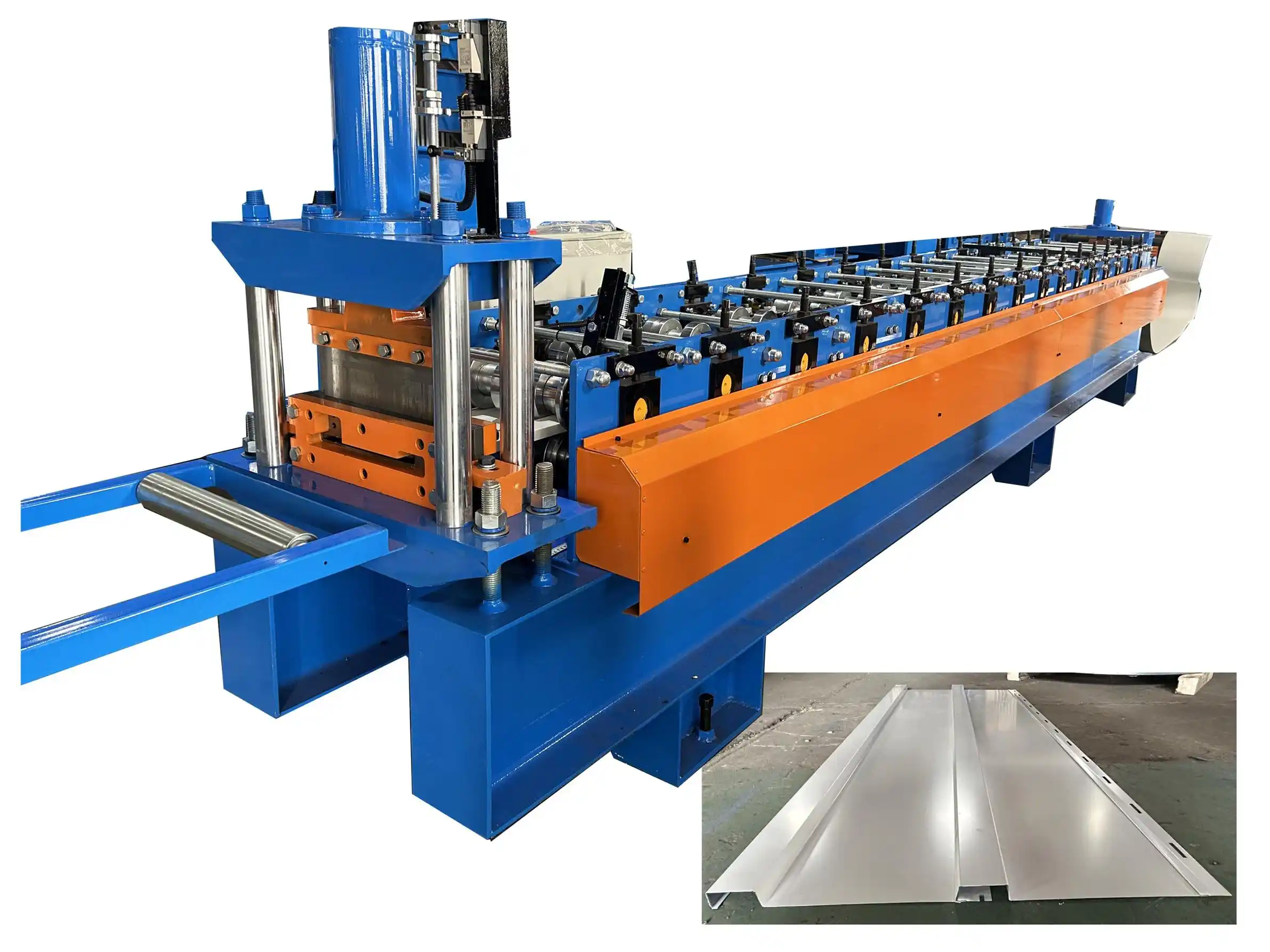

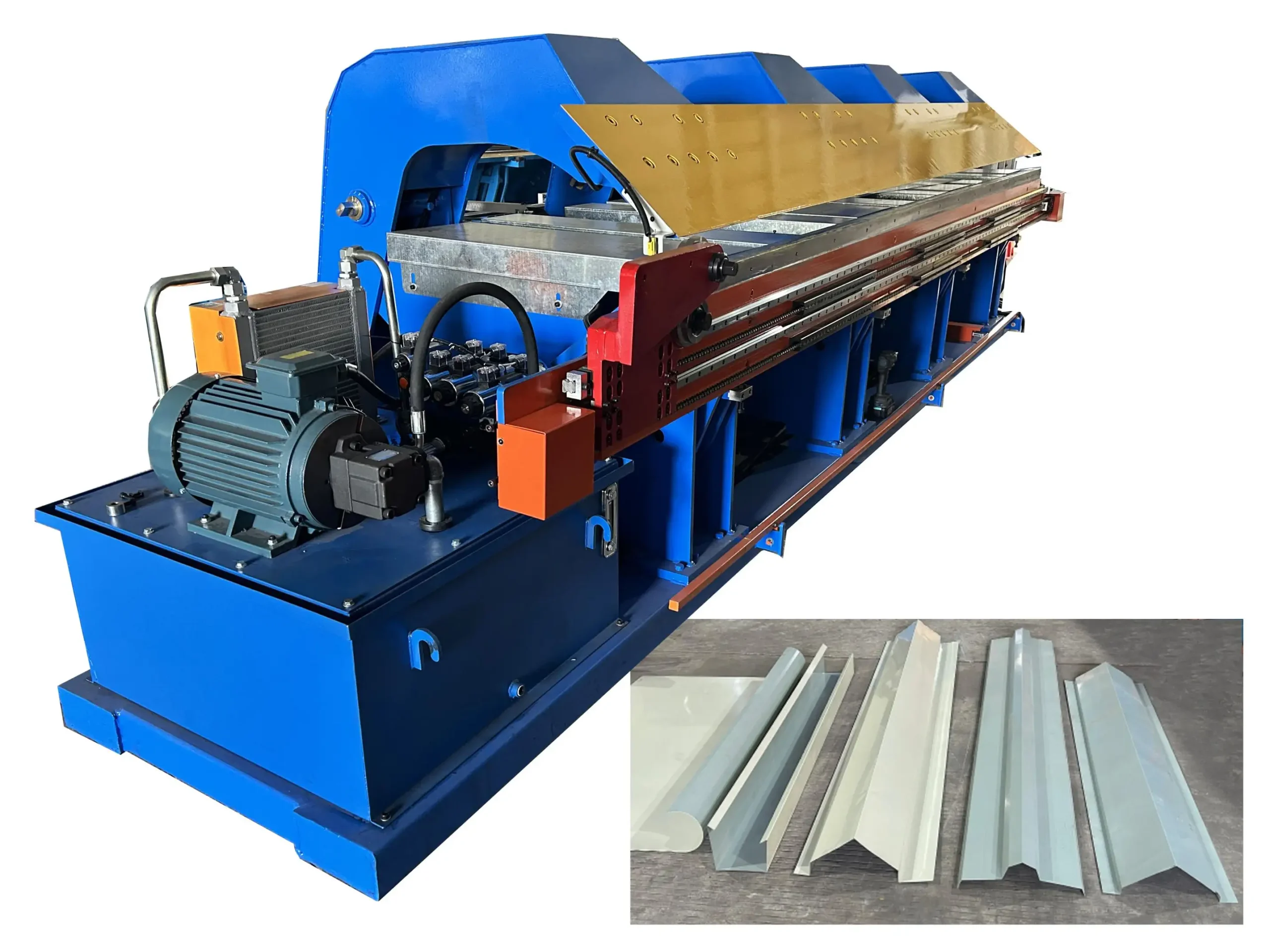

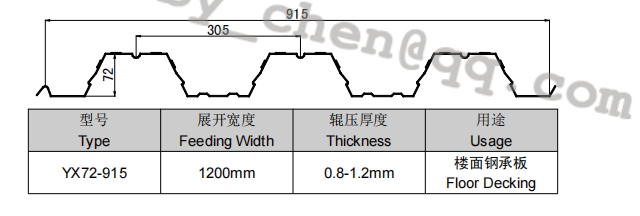

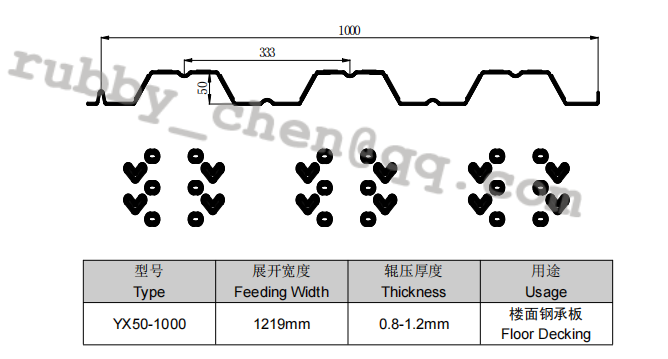

Popular Floor Decking Profiles

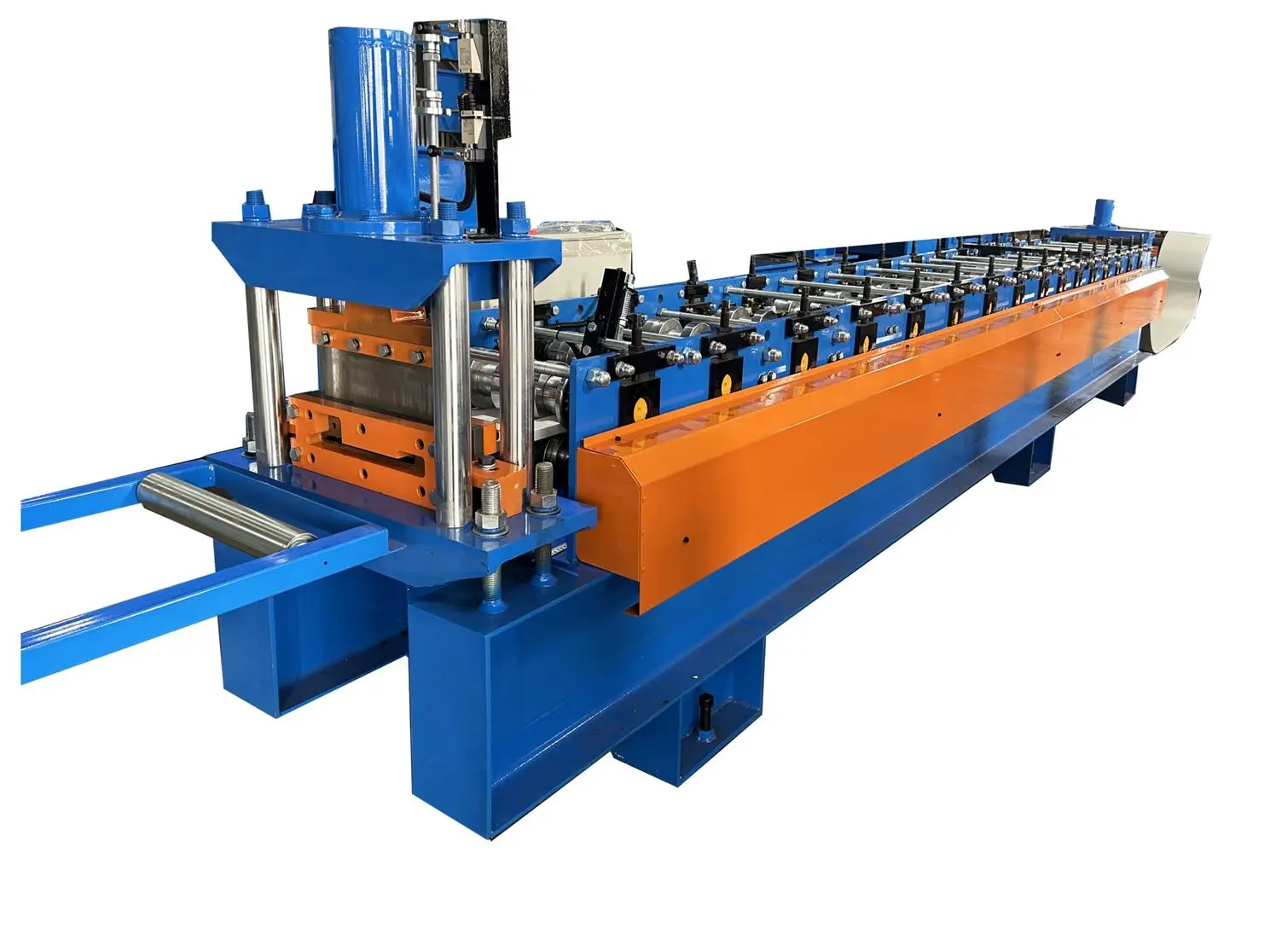

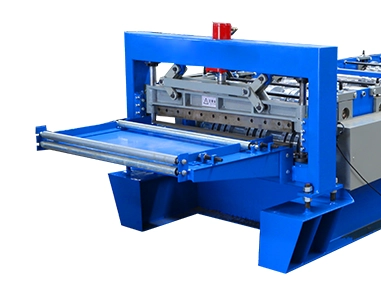

Components of Floor Decking Machine

- Alimentazione Directional guide wheels ensure that the material is guided into the correct position

- Pretaglio idraulico The thickness of the floor deck is usually 0.8-1.2mm, so it is equipped with hydraulic front shears, which greatly saves manpower.

- Rulli della macchina per la posa di pavimenti

I rulli sono realizzati in acciaio per cuscinetti di alta qualità GCr15, torniti CNC, trattati termicamente e disponibili con rivestimento in cromo duro.

Con guida per l'alimentazione del materiale, struttura del corpo realizzata in acciaio tipo H 300# mediante saldatura

- Taglierina per la formazione di decking per pavimenti

Realizzato in acciaio per stampi di alta qualità Cr12 con trattamento termico

- Sistema di controllo PLC

Facile da usare

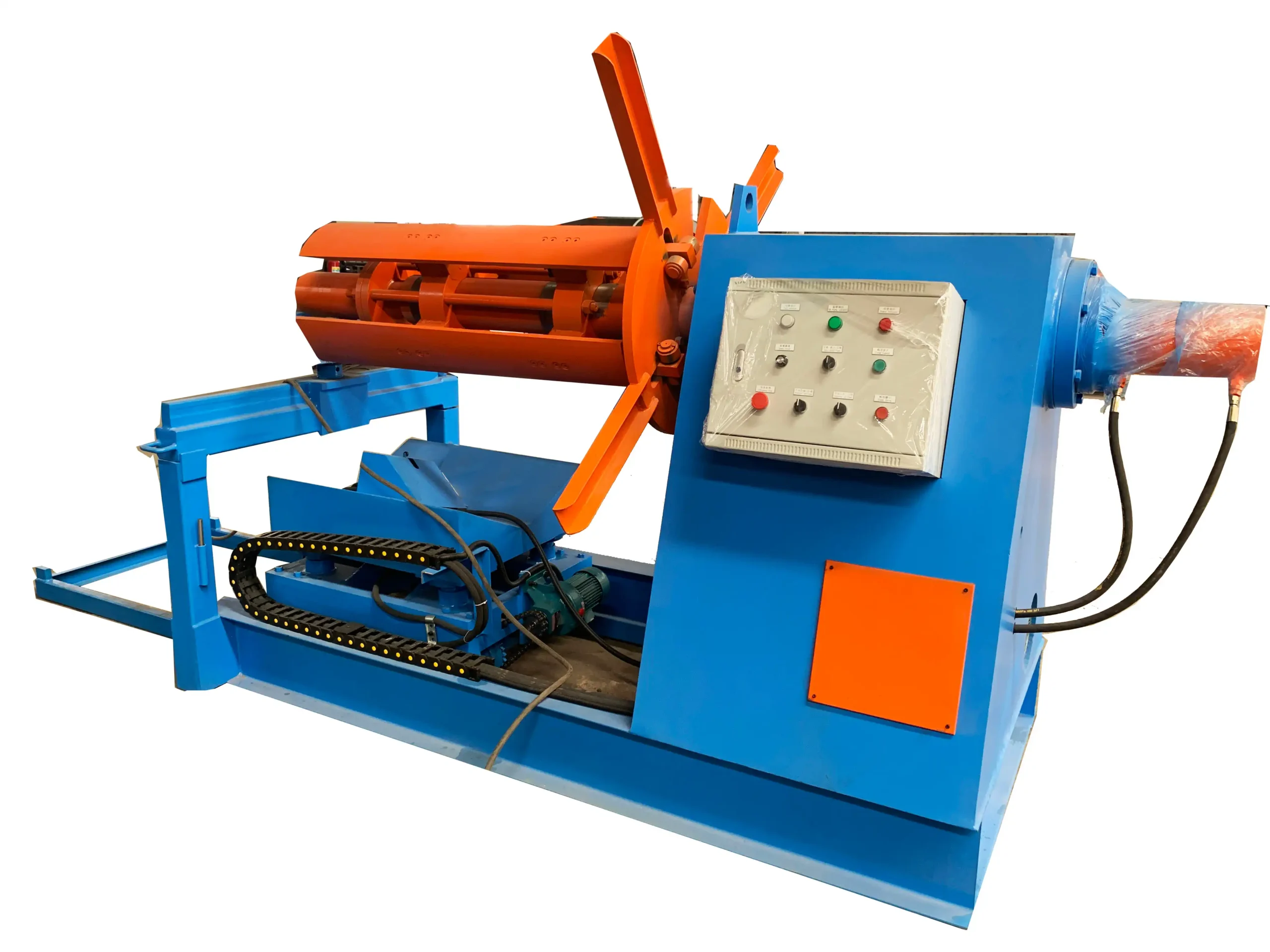

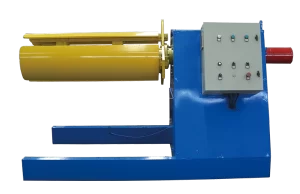

6.Decoiler

Decoiler manuale: un set

Non alimentato, controlla manualmente il restringimento e l'arresto del foro interno della bobina d'acciaio

Larghezza massima di alimentazione: 1250 mm, intervallo ID bobina 480 mm±30 mm

Capacità: Max. 5 tonnellate

Con aspirapolvere idraulico da 5 tonnellate con e senza macchina a scelta

Our Service

Raw Material Selection: To ensure the strength and wear resistance of the product, we use high-quality steel, such as Cr12 die steel and GCr15 bearing steel, when producing metal floor slabs.

Processing Technology: Heat treatment technology is used to improve material performance, and CNC machine tools are used for precision processing. To further improve wear resistance, the roller surface is hard chrome plated.

All the shafts of the machine are solid shafts, which can ensure the stability, precision and durability of the product.

Strict quality control: To ensure that each equipment meets customer requirements and national standards, strict quality control is implemented in each production link from raw material procurement to assembly and commissioning.

Servizio post-vendita

Equipment Installation and Commissioning: To ensure that the equipment is smoothly put into production, we provide equipment installation, commissioning and trial operation services.

Operation Training: To ensure that operators are proficient in the use and maintenance of equipment, we provide operation training for customers.

Maintenance: Provide daily maintenance and upkeep services to ensure long-term stable operation of the equipment.

Technical support: Provide technical support and consulting services to customers to help solve problems encountered during use.