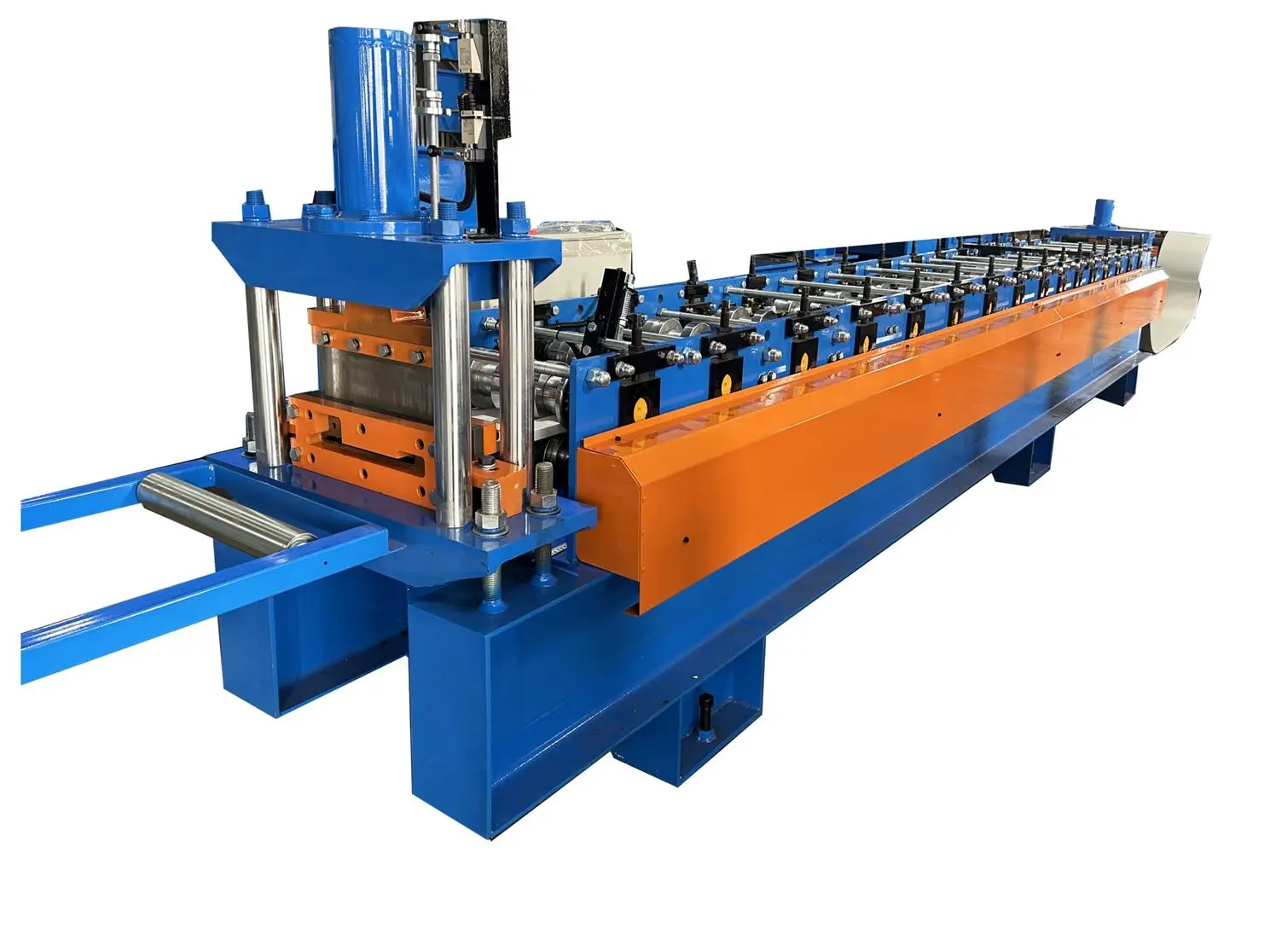

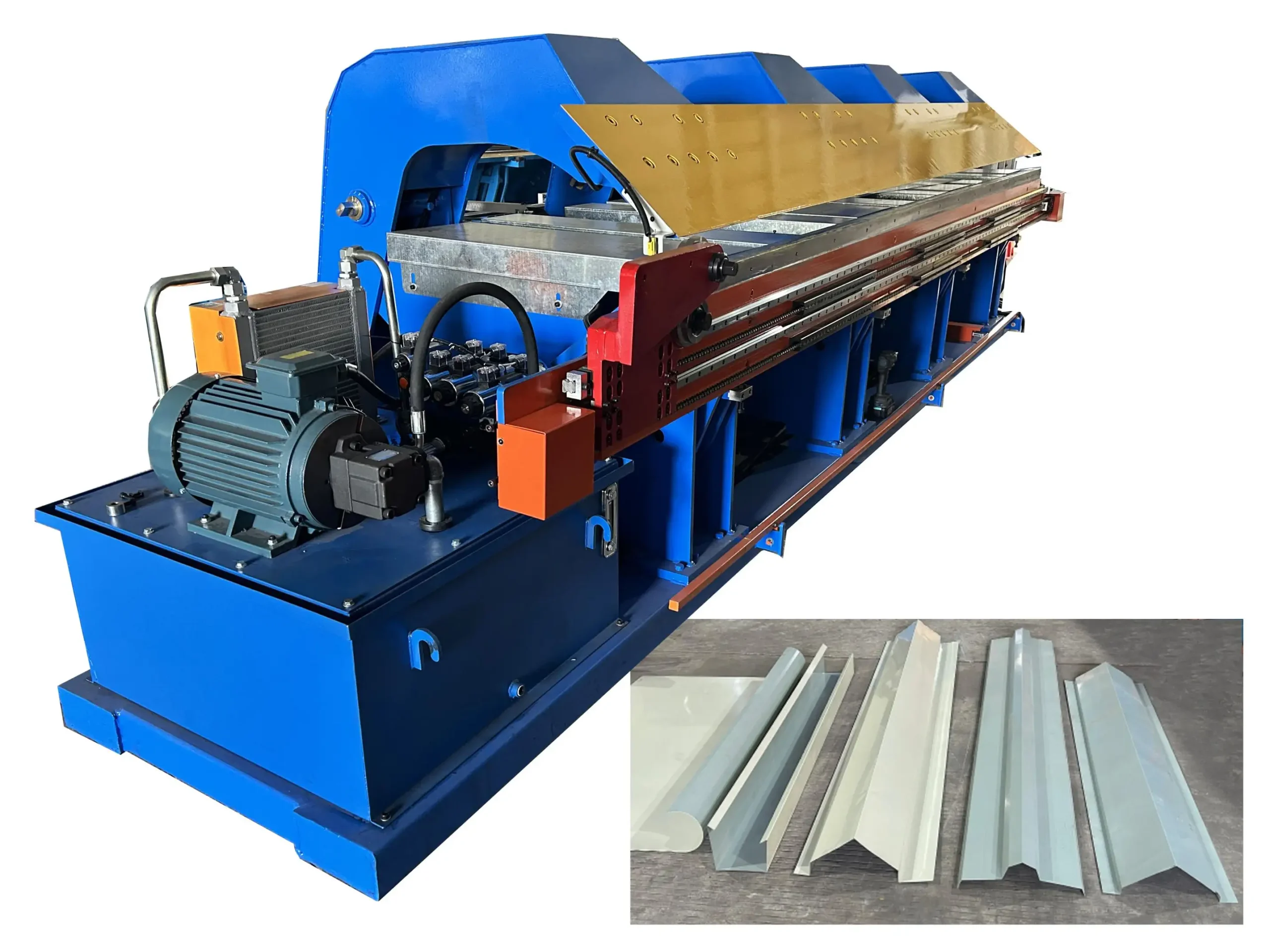

To meet the industrial production requirements of C and Z purlins for steel structures, the modern CZ purlin CNC roll forming machine adopts an innovative integrated cold forming process system to achieve high-precision, intelligent metal profile processing. This equipment system demonstrates the following technical features:

- The modular design concept allows for the configuration of automated control systems at different levels according to production capacity demands.

- With a high-precision servo drive system, it achieves a forming accuracy of ±0.15mm/m.

- Incorporates a rapid die-changing function capable of switching product specifications within 15 minutes.

Feature of CZ Purlin Machine

**High-Efficiency Production:** The advanced forming process and high-speed transmission system enable rapid production and cutting of C & Z purlins. Depending on model configurations, the equipment can achieve large-scale manufacturing to meet the demands of major construction projects.

**Precision Processing:** With high-accuracy forming molds and an intelligent control system, the machine ensures dimensional consistency and structural stability of the purlins. The state-of-the-art processing technology allows for customized C & Z purlin production tailored to specific engineering requirements.

**User-Friendly Operation:** The intuitive human-machine interface (HMI) simplifies operation, allowing easy setup, production control, and quick mold changeovers. The intelligent monitoring system provides real-time feedback on production data and equipment status, enhancing operational management efficiency.

**High Flexibility:** By adjusting molding dies and control parameters, the machine supports manufacturing purlins in various sizes and specifications, adaptable to diverse project needs. Seamless switching between C- and Z-type purlin production is achievable for enhanced workflow efficiency.

**Robust & Reliable Performance:** Constructed with premium materials and engineered with precision manufacturing techniques, the equipment ensures long-term stability and durability under continuous operation. Its comprehensive safety protection system prevents overload, overheating, and mechanical failures, minimizing downtime.

Details of the CZ Purlin Machine

**Structural Capabilities & Applications**

Heavy-duty CZ purlins are critical load-bearing elements in modern steel structures, designed to deliver superior stability and strength for demanding construction applications.

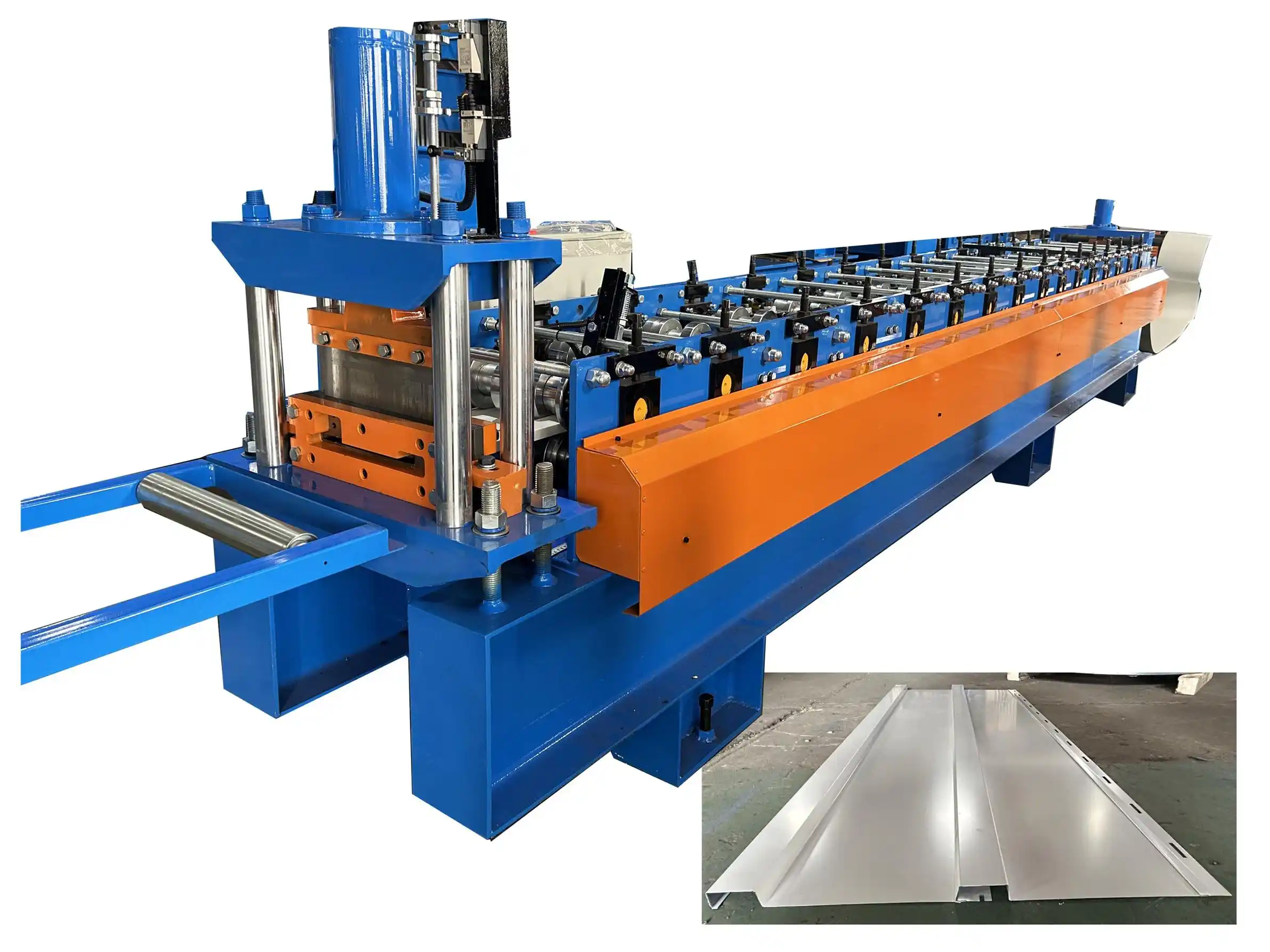

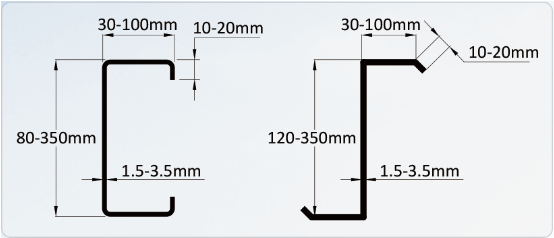

– **C-Purlins**: Fabricated from high-grade hot-rolled steel strips, these components feature a **C-shaped cross-section** optimized for structural rigidity and vertical load resistance. Their design ensures reliable support in roofing and wall framing systems.

– **Z-Purlins**: Engineered with thicker steel strips in a **Z-profile configuration**, these purlins provide enhanced bending resistance and load distribution—ideal for long-span structures requiring high-tensile performance.

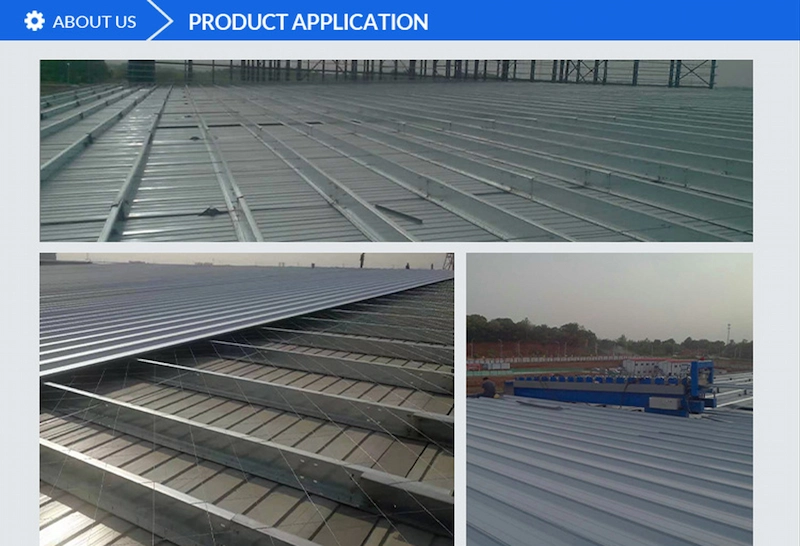

**Industrial Applications**

Heavy-duty CZ purlins are extensively utilized in:

**Large-span infrastructure** (aircraft hangars, industrial warehouses, stadiums)

**High-load buildings** (manufacturing plants, logistics centers)

**Seismic-resistant structures** (improves stability while reducing deformation under stress)

The precision-engineered design of these components enhances structural integrity, ensuring durability even in extreme conditions.

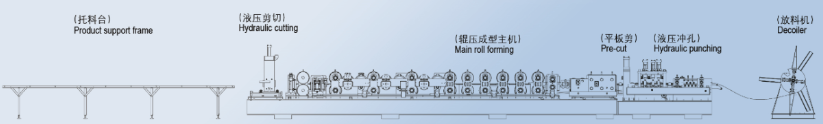

Heavy-duty automatic CZ purlin plate rolling machine main parts description

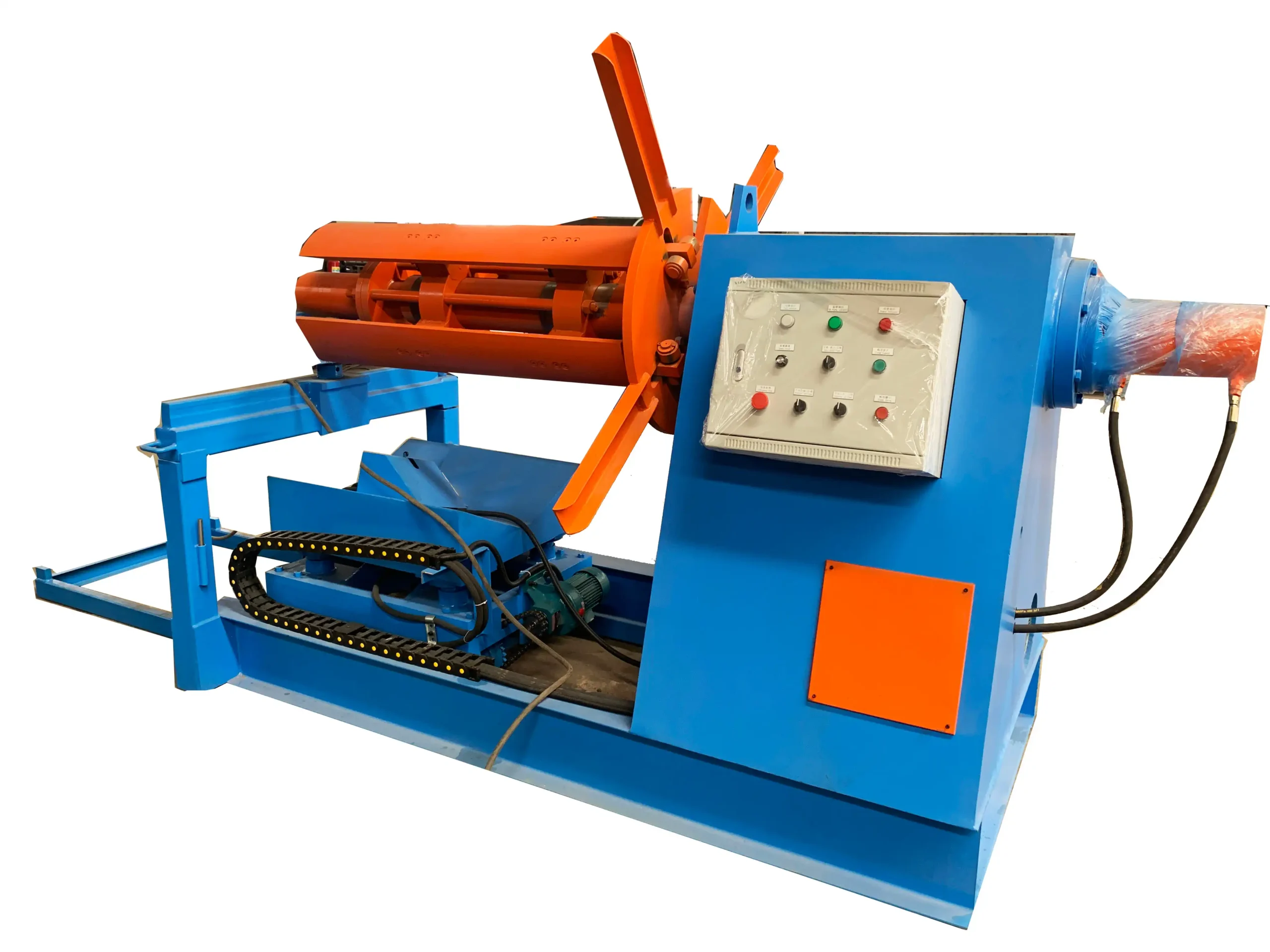

Hydraulic uncoiler

Uncoiler type: designed with automatic tightening and loosening functions, convenient for fast loading and unloading of materials.

Weight capacity: capable of carrying up to 10 tons of coils, meeting the needs of large-scale production.

Feeding and leveling device

Function: before the material is fed into the roll forming machine, ensure that the surface of the material is flat and wrinkle-free, providing high-quality raw material state for subsequent forming processing.

Hydraulic pre-cutting and punching device

Pre-cutting function: precise cutting of raw materials before roll forming.

Punching function: Punching operation is performed on flat materials, the position and number of punching holes are accurately controlled by PLC, the horizontal position is automatically adjusted, and the vertical position can be manually fine-tuned.

Customization: The number and size of punching holes on the web and flange can be customized according to the specific requirements of customers.

Convenience: The punching rod and punching die are designed to be easy to replace to meet different production needs.

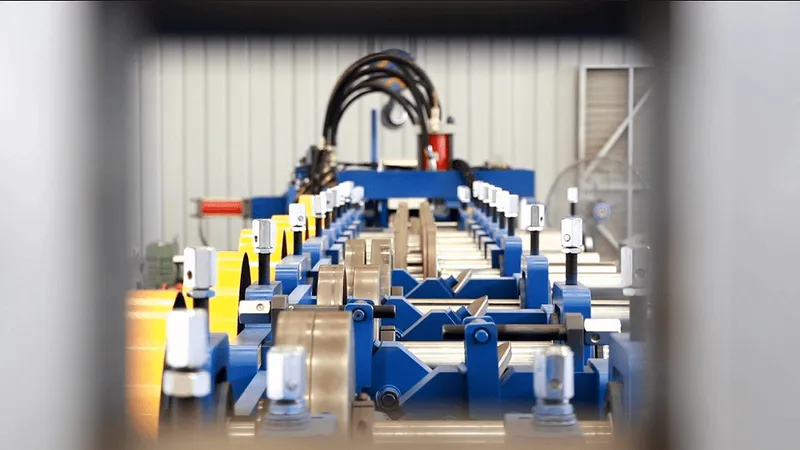

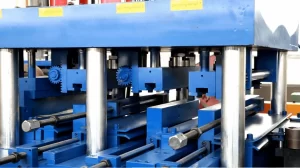

Main machine

Drive mode: Adopt efficient gearbox drive to ensure the stability and efficiency of transmission.

Forming speed: adjustable range is 0-30 m/min, flexible to adapt to different production rhythms.

Roller configuration: about 24 sets of rollers, made of Cr12 mold steel, to ensure the accuracy and durability of forming.

Lower roller diameter: about 360 mm, providing sufficient pressure and contact area to ensure the quality of forming.

Roller shaft processing: after two grinder processing, to ensure the accuracy and durability of the shaft, thereby ensuring the accuracy of the finished product.

Spindle material: 40Cr material is used, which has both strength and toughness to meet the needs of long-term high-intensity work.

Rear hydraulic cutting device

Innovative cutting system: the company’s innovative cutting technology is used to ensure the accuracy and efficiency of cutting.

CZ integrated adjustable cutting mold: the unique design makes it unnecessary to replace the cutting mold when the purlin size changes, greatly improving the flexibility and efficiency of production. This design not only reduces the time for changing the mold, but also reduces the production cost, while ensuring the consistency and quality of cutting.