High Pressure Rubber Belt Sandwich Panel Machine Advantages

Modern building materials must meet key technical specifications including strength performance, density control, installation convenience, structural stability, and long-term durability. High-pressure polyurethane (PU) foam technology not only fulfills these requirements but also exhibits outstanding flame resistance and insulation properties. Due to these technical advantages, high-pressure PU materials are widely applied across multiple construction sectors, including cold chain storage, medical refrigeration, automotive manufacturing, sports arenas, and high-end residential projects. Our factory’s PU production line adopts high-pressure foaming technology, achieving industry-leading performance levels.

Advantages of High Pressure Sandwich Panel Line:

1. **Flame Resistance** – Complies with B2-grade fireproofing standards for building materials.

2. **Insulation Performance** – Meets thermal conductivity requirements for professional cold chain facilities.

3. **Advanced Mixing Process** – High-pressure blending ensures homogeneous material distribution, creating denser foam cell structures, improving product lifespan by **30%+**.

4. **Higher Material Efficiency** – Compared to low-pressure processes, **7-9% less raw material consumption**, significantly lowering production costs.

5. **Self-Cleaning Nozzle System** – Proprietary automatic cleaning eliminates manual maintenance, reducing downtime by **50%**.

6. **Intelligent Flying Cutting System** – Fully automated operation cuts labor costs by **60%**.

7. **Multi-Layer Pressure Monitoring** – Ensures **safe and stable** machine operation.

**Optional Product Configurations:**

1. **PU Composite Panels** (metal/PVC surface, Thickness: **18-22mm or 22-25mm**)

2. **Double-Metal Sheets** (standard **25mm & 50mm** thickness)

Diagramma di flusso

Profili popolari di coperture e pareti

Video in esecuzione

Componenti della macchina per pannelli sandwich

2 serie di aspirapolvere idraulici da 5 tonnellate con vagone di carico

** Multi-Level Feeding System for Enhanced Roll Forming Performance**

Our unloading system to deliver synchronized material distribution to both upper and lower roll forming stations. This innovative stratification enables:

1. **Independent Material Management**

– Upper deck: Precision-calibrated for optimal feed to top-tier roll formers

– Lower deck: Engineered for flawless material routing to bottom-tier forming units

2. **Smart Flow Regulation Technology**

• Real-time feed rate adjustment through controlled mechanisms

• Embedded optical sensors for continuous material tracking

3. **Production Optimization Benefits**

– 10% reduction in material transfer fluctuations (vs conventional single-tier systems)

– Elimination of cross-tier interference through isolated control circuits

4.The system’s modular design allows seamless integration with existing roll forming lines while delivering:

✓ 8-9% throughput enhancement

This advancement represents a fundamental improvement in continuous manufacturing processes.

2 set di macchine formatrici di rotoli

Double Roll Forming Machine: Two of the most important machines on the production line are the double roll forming machines. They are essential to the production process because they ensure that the raw materials can be formed synchronously, accurately and efficiently. In order to meet the product requirements, the forming machine uses roll forming to process the raw materials into preset sizes and shapes.

The double-layer machine can be controlled by PLC, with two layers produced synchronously, or it can only run a single layer

The stable operation of this equipment not only improves production efficiency, but also ensures product consistency and excellent quality.

1 set di sistema di schiumatura PU ad alta pressione

**Principle and comparison of high-pressure foaming and low-pressure foaming of polyurethane**

1. Low-Pressure Foaming

Principle:

Mechanical mixing: Mix material A (isocyanate) and material B (polyol + additives) by low-speed stirring (200-1000 rpm), and inject them into the mold by gravity or low pressure.

Chemical reaction: Isocyanate (-NCO) reacts with polyol (-OH) to form polyurethane, accompanied by the formation of CO₂ bubbles (foaming agent effect).

Caratteristiche:

– The mixing accuracy is low, and problems such as uneven bubbles and inconsistent density are prone to occur.

2. High-Pressure Foaming

Principle:

High-pressure impact mixing: A and B materials are accurately measured under high pressure (100-200 bar) and instantly mixed (mixing time <1ms) by high-precision collision mixing heads (such as Hennecke, Cannon).

-Atomization mixing: High pressure makes the raw materials atomized to ensure uniform mixing at the molecular level.

Core advantages of high-pressure foaming:

1. More uniform mixing and finer pores

– High-pressure atomization can reduce dead zones and avoid defects caused by unmixed materials (such as lumps and uneven bubbles).

2. Higher production efficiency

– Suitable for automated continuous production.

3. Less material waste

– The mixing head is self-cleaning, with a residual amount of <0.1%, which reduces raw material loss and can save 7-9% of raw materials compared to low-pressure foaming.

4. Better product performance

– The pore structure is more uniform.

High-pressure foaming technology is superior to low-pressure foaming in terms of mixing accuracy, production efficiency and product performance, and is particularly suitable for high-end manufacturing.

1 set di macchine host pu

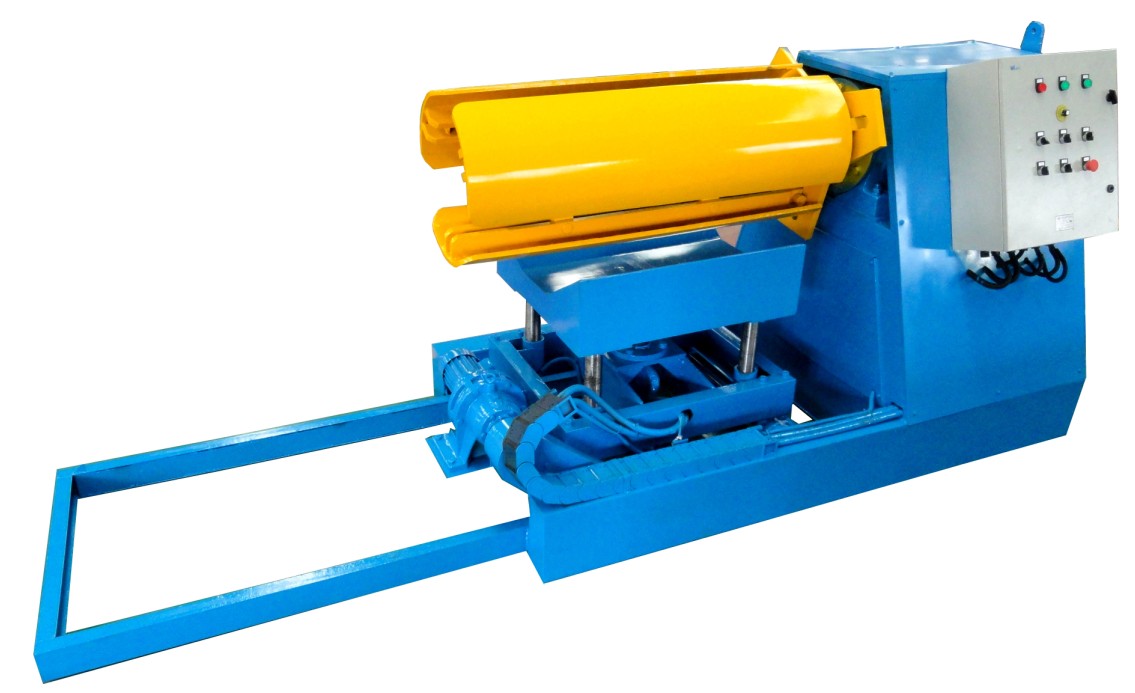

La lunghezza del mainframe in PU è solitamente compresa tra 25 e 30 metri, determinata dai disegni forniti dal cliente e dallo spessore di schiumatura richiesto. Per soddisfare al meglio le esigenze produttive dei clienti, l'apparecchiatura è stata progettata tenendo conto della diversità e della flessibilità delle specifiche dei prodotti, in modo da potersi adattare a vari scenari produttivi.

Il nostro mainframe adotta un sistema di trasmissione a cinghia di gomma, che non solo garantisce la stabilità e l'efficienza dell'apparecchiatura durante il funzionamento, ma riduce anche in modo significativo il costo di produzione della macchina. Rispetto ai metodi di trasmissione tradizionali, le cinghie di gomma sono eccellenti nell'assorbimento degli urti e nella resistenza all'usura, prolungando così la vita utile dell'apparecchiatura, riducendo la frequenza di manutenzione e risparmiando i successivi costi operativi per le imprese.

1 Sistema di controllo PLC completo

L'intera macchina principale è composta da 3 parti: macchina formatrice di rotoli, sistema di schiumatura PU e sistema di cesoiatura. Ogni parte è dotata di un sistema di controllo elettronico indipendente e i 3 sistemi possono essere gestiti in modo intelligente online.

1 Sistema di taglio volante

Sistema di taglio con servomotore: Il sistema di taglio utilizza un servomotore ad alta precisione per garantire il taglio preciso delle lastre di poliuretano e può tagliare in modo rapido, accurato e stabile materiali di varie dimensioni e requisiti. È inoltre dotato di uno speciale collettore di polveri, igienico e bello.

Applicazioni