High Pressure Rubber Belt Sandwich Panel Machine Advantages

Modern building materials must meet key technical specifications including strength performance, density control, installation convenience, structural stability, and long-term durability. High-pressure polyurethane (PU) foam technology not only fulfills these requirements but also exhibits outstanding flame resistance and insulation properties. Due to these technical advantages, high-pressure PU materials are widely applied across multiple construction sectors, including cold chain storage, medical refrigeration, automotive manufacturing, sports arenas, and high-end residential projects. Our factory’s PU production line adopts high-pressure foaming technology, achieving industry-leading performance levels.

Advantages of High Pressure Sandwich Panel Line:

1. **Flame Resistance** – Complies with B2-grade fireproofing standards for building materials.

2. **Insulation Performance** – Meets thermal conductivity requirements for professional cold chain facilities.

3. **Advanced Mixing Process** – High-pressure blending ensures homogeneous material distribution, creating denser foam cell structures, improving product lifespan by **30%+**.

4. **Higher Material Efficiency** – Compared to low-pressure processes, **7-9% less raw material consumption**, significantly lowering production costs.

5. **Self-Cleaning Nozzle System** – Proprietary automatic cleaning eliminates manual maintenance, reducing downtime by **50%**.

6. **Intelligent Flying Cutting System** – Fully automated operation cuts labor costs by **60%**.

7. **Multi-Layer Pressure Monitoring** – Ensures **safe and stable** machine operation.

**Optional Product Configurations:**

1. **PU Composite Panels** (metal/PVC surface, Thickness: **18-22mm or 22-25mm**)

2. **Double-Metal Sheets** (standard **25mm & 50mm** thickness)

흐름도

지붕 및 벽의 인기 프로파일

실행 중인 비디오

샌드위치 패널 기계의 구성 요소

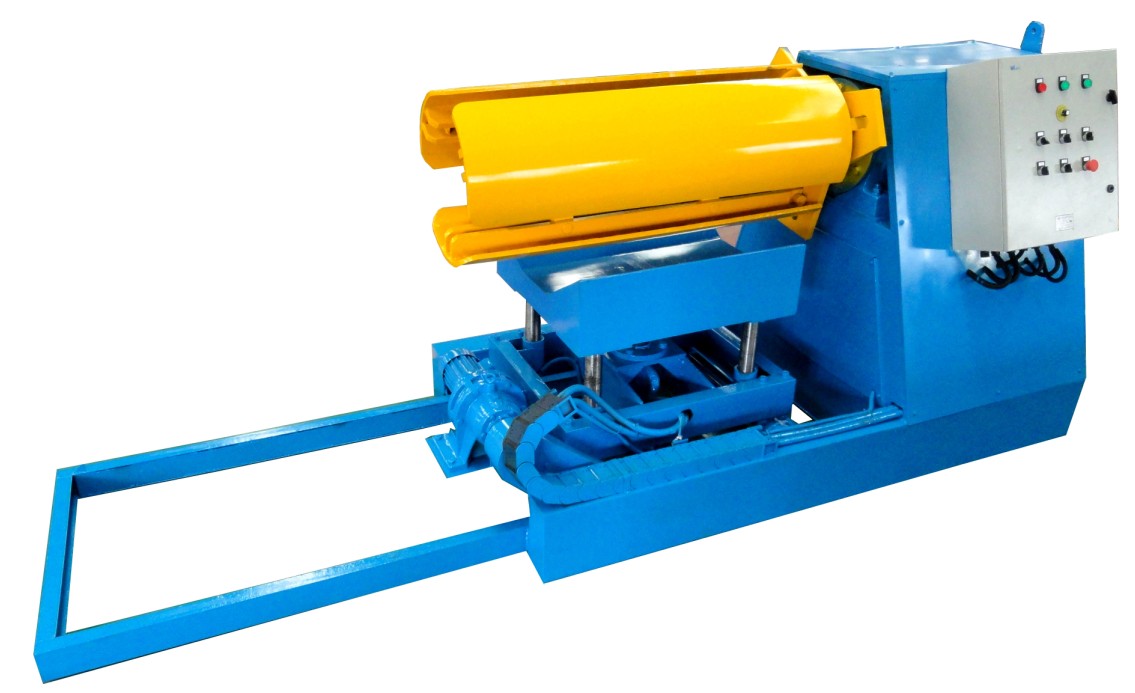

적재 차량이 있는 5톤 유압 디코일러 2세트

** Multi-Level Feeding System for Enhanced Roll Forming Performance**

Our unloading system to deliver synchronized material distribution to both upper and lower roll forming stations. This innovative stratification enables:

1. **Independent Material Management**

– Upper deck: Precision-calibrated for optimal feed to top-tier roll formers

– Lower deck: Engineered for flawless material routing to bottom-tier forming units

2. **Smart Flow Regulation Technology**

• Real-time feed rate adjustment through controlled mechanisms

• Embedded optical sensors for continuous material tracking

3. **Production Optimization Benefits**

– 10% reduction in material transfer fluctuations (vs conventional single-tier systems)

– Elimination of cross-tier interference through isolated control circuits

4.The system’s modular design allows seamless integration with existing roll forming lines while delivering:

✓ 8-9% throughput enhancement

This advancement represents a fundamental improvement in continuous manufacturing processes.

롤 성형기 2세트

Double Roll Forming Machine: Two of the most important machines on the production line are the double roll forming machines. They are essential to the production process because they ensure that the raw materials can be formed synchronously, accurately and efficiently. In order to meet the product requirements, the forming machine uses roll forming to process the raw materials into preset sizes and shapes.

The double-layer machine can be controlled by PLC, with two layers produced synchronously, or it can only run a single layer

The stable operation of this equipment not only improves production efficiency, but also ensures product consistency and excellent quality.

고압 PU 발포 시스템 1세트

**Principle and comparison of high-pressure foaming and low-pressure foaming of polyurethane**

1. Low-Pressure Foaming

Principle:

Mechanical mixing: Mix material A (isocyanate) and material B (polyol + additives) by low-speed stirring (200-1000 rpm), and inject them into the mold by gravity or low pressure.

Chemical reaction: Isocyanate (-NCO) reacts with polyol (-OH) to form polyurethane, accompanied by the formation of CO₂ bubbles (foaming agent effect).

기능:

– The mixing accuracy is low, and problems such as uneven bubbles and inconsistent density are prone to occur.

2. High-Pressure Foaming

Principle:

High-pressure impact mixing: A and B materials are accurately measured under high pressure (100-200 bar) and instantly mixed (mixing time <1ms) by high-precision collision mixing heads (such as Hennecke, Cannon).

-Atomization mixing: High pressure makes the raw materials atomized to ensure uniform mixing at the molecular level.

Core advantages of high-pressure foaming:

1. More uniform mixing and finer pores

– High-pressure atomization can reduce dead zones and avoid defects caused by unmixed materials (such as lumps and uneven bubbles).

2. Higher production efficiency

– Suitable for automated continuous production.

3. Less material waste

– The mixing head is self-cleaning, with a residual amount of <0.1%, which reduces raw material loss and can save 7-9% of raw materials compared to low-pressure foaming.

4. Better product performance

– The pore structure is more uniform.

High-pressure foaming technology is superior to low-pressure foaming in terms of mixing accuracy, production efficiency and product performance, and is particularly suitable for high-end manufacturing.

PU 호스트 머신 1세트

PU 메인프레임의 길이는 일반적으로 25~30미터이며, 이는 고객이 제공한 도면과 필요한 발포 두께에 따라 결정됩니다. 고객의 생산 요구를 더 잘 충족시키기 위해 장비는 다양한 제품 사양의 다양성과 유연성을 충분히 고려하여 다양한 생산 시나리오에 적응할 수 있도록 설계되었습니다.

당사의 메인프레임은 고무 벨트 전송 시스템을 채택하여 작동 중 장비의 안정성과 효율성을 보장할 뿐만 아니라 기계의 제조 비용도 크게 절감합니다. 기존의 전송 방식에 비해 고무 벨트는 충격 흡수 및 내마모성이 우수하여 장비의 수명을 연장하고 유지 보수 빈도를 줄이며 기업의 후속 운영 비용을 절감합니다.

1 PLC 제어 시스템 전체 세트

전체 메인 기계는 롤 성형기, PU 발포 시스템, 전단 시스템의 세 부분으로 구성됩니다. 각 부품에는 독립적인 전자 제어 시스템이 있으며, 3개의 시스템은 온라인으로 지능적으로 작동할 수 있습니다.

1 플라잉 커팅 시스템

서보 모터 커팅 시스템: 절단 시스템은 고정밀 서보 모터를 사용하여 폴리우레탄 시트를 정밀하게 절단하고 다양한 크기와 요구 사항의 재료를 빠르고 정확하고 안정적으로 절단할 수 있습니다. 또한 위생적이고 아름다운 특수 집진기가 장착되어 있습니다.

애플리케이션